ENGINES - 3A-3390-823225--1 1096

!

CAUTION

The head gasket may be holding cylinder head to

block. Use care when prying off cylinder heads.

DO NOT damage gasket surfaces. DO NOT drop

cylinder heads.

3. Place cylinder head on wooden blocks to prevent

damage to gasket surfaces.

Cleaning and Inspection

1. Clean gasket material and sealer from engine

block and cylinder heads.

2. Inspect sealing surfaces for deep nicks and

scratches.

3. Inspect for corrosion around cooling passages.

4. Clean head bolt threads and engine block bolt

hole threads, making sure no dirt, old oil or cool-

ant remain.

Installation

!

CAUTION

When using ribbed stainless steel head gaskets,

apply a thin coating of Quicksilver Perfect Seal to

both sides of gasket. Too much sealer may hold

gasket away from head or block causing leakage.

DO NOT use sealer on graphite composition

head gaskets.

1. Place head gasket in position over dowel pins.

2. Carefully set cylinder head in place over dowel

pins.

3. Coat threads of head bolts with Quicksilver Per-

fect Seal and install finger-tight.

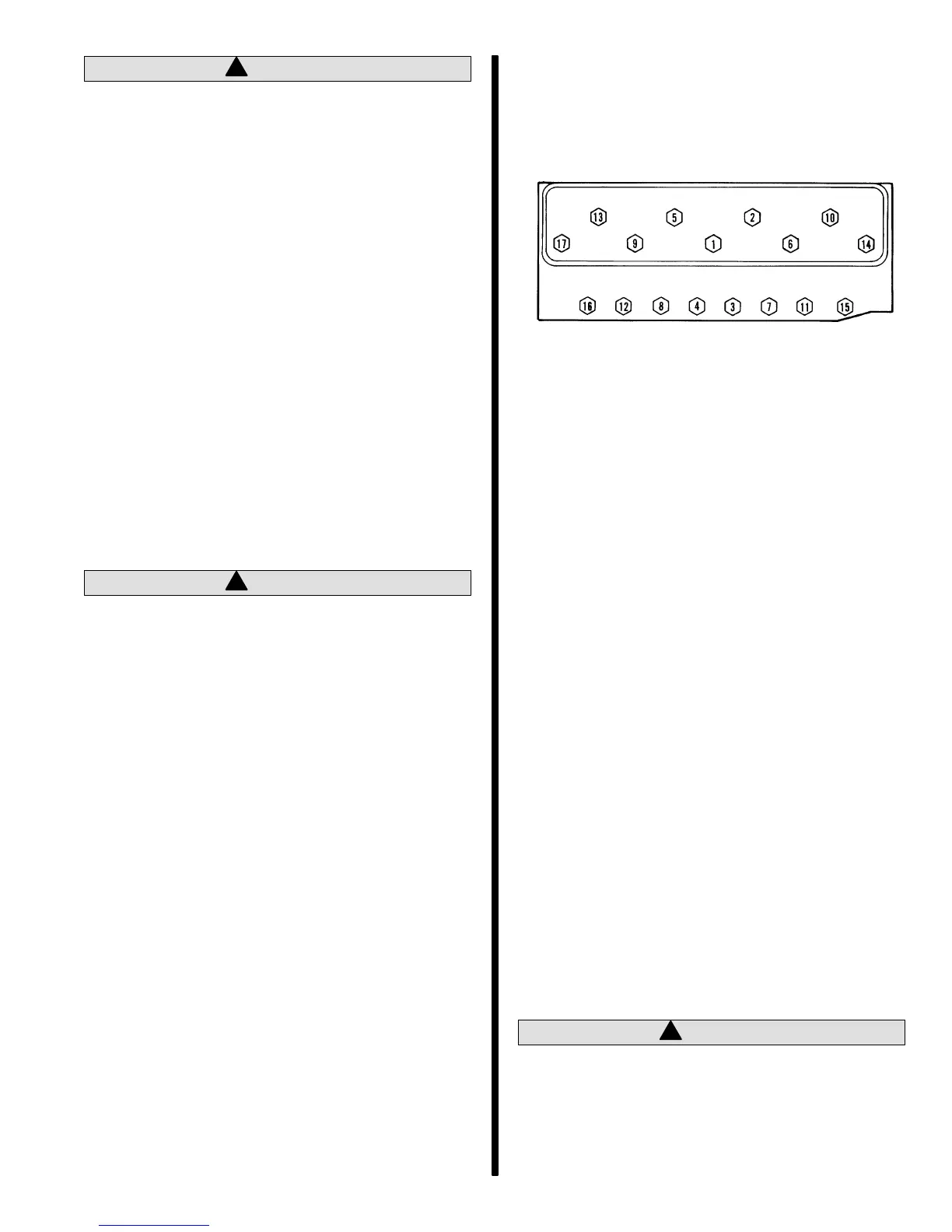

a. All Engines Except Gen+: Torque head

bolts in three steps, following torque se-

quence for each step. Start first step at 20 lb.

ft. (27 N·m), second step at 40 lb. ft. (54 N·m),

and finish with a final torque of 65 lb. ft. (88

N·m).

72332

b. Gen+ Engines Only: Torque cylinder heads

in two steps. Initial pass, torque all bolts to 22

lb. ft. (30 N·m). Second pass is an angle

torque sequence:

short bolts 55 degrees

medium bolts 65 degrees

long bolts 75 degrees

4. Install push rods and rocker arm assemblies in

their original positions. On roller cam engines

only, install baffle plate and retainers.

5. Adjust valves as outlined under “Valve Adjust-

ment - Engine Stopped.”

6. Install as outlined:

a. Intake manifold.

b. Rocker arm covers.

c. Exhaust manifolds.

d. Spark plugs.

e. Any components removed from front or rear

of cylinder heads.

7. Follow procedures in Section 6A or 6B of this

manual:

Seawater Cooled Models: Provide for adequate

water supply to seawater pickup (see Section

6A).

Closed Cooled Models: Refill closed cooling

section (see Section 6B), and provide adequate

water supply to seawater pickup.

!

CAUTION

Ensure that cooling water supply is available be-

fore starting the engine.

8. Start engine, set timing, set idle speed, and

check for leaks.

Loading...

Loading...