ENGINES - 3A-5390-823225--1 1096

When a production crankshaft cannot be precision

fitted by this method, it is then ground .009 in. under-

size ON ONLY THOSE MAIN JOURNALS THAT

CANNOT BE PROPERLY FITTED. ALL JOURNALS

WILL NOT NECESSARILY BE GROUND UNDER-

SIZE. A .009 in. undersize bearing and .010 in. un-

dersize bearing may be used for precision fitting in

the same manner as previously described.

Inspection

In general, the lower half of the bearing (except

No. 1 bearing) shows a greater wear and the most

distress from fatigue. If, upon inspection, the lower

half is suitable for use, it can be assumed that

the upper half is also satisfactory. If the lower half

shows evidence of wear or damage, both upper

and lower halves should be replaced. Never re-

place one half without replacing the other half.

Checking Clearances

To obtain accurate measurements while using Plasti-

gage, or its equivalent, engine must be out of the boat

and upside down so crankshaft will rest on the upper

bearings and total clearance can be measured be-

tween lower bearing and journal.

To assure the proper seating of the crankshaft, all

bearing cap bolts should be at their specified torque.

In addition, preparatory to checking fit of bearings,

the surface of the crankshaft journal and bearing

should be wiped clean of oil.

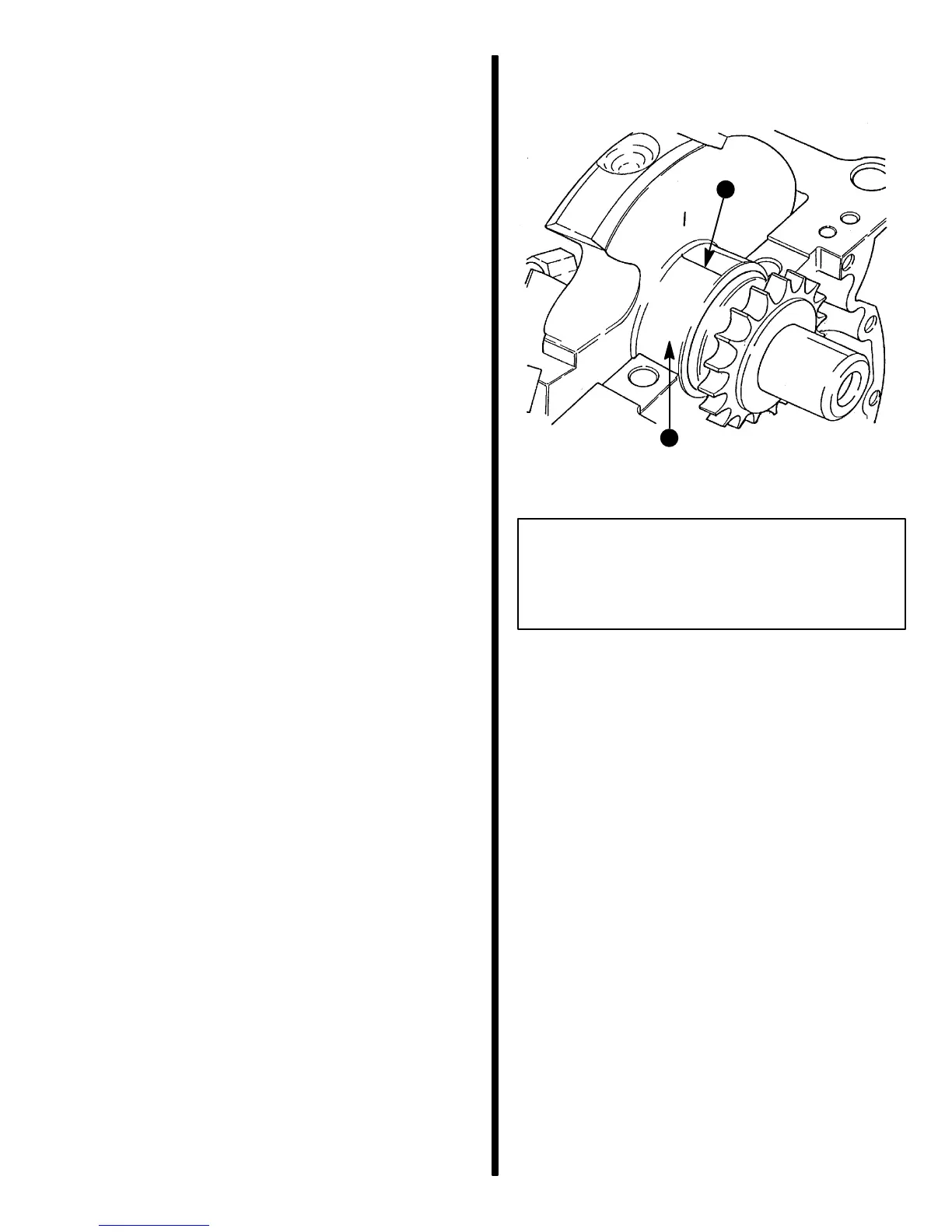

1. With the oil pan and oil pump removed, remove

bearing cap and wipe oil from journal and bearing

cap to be inspected.

2. Place a piece of gauging plastic the full width of

the bearing (parallel to the crankshaft) on the

journal as shown.

72357

a - Gauging Plastic

b - Journal

b

a

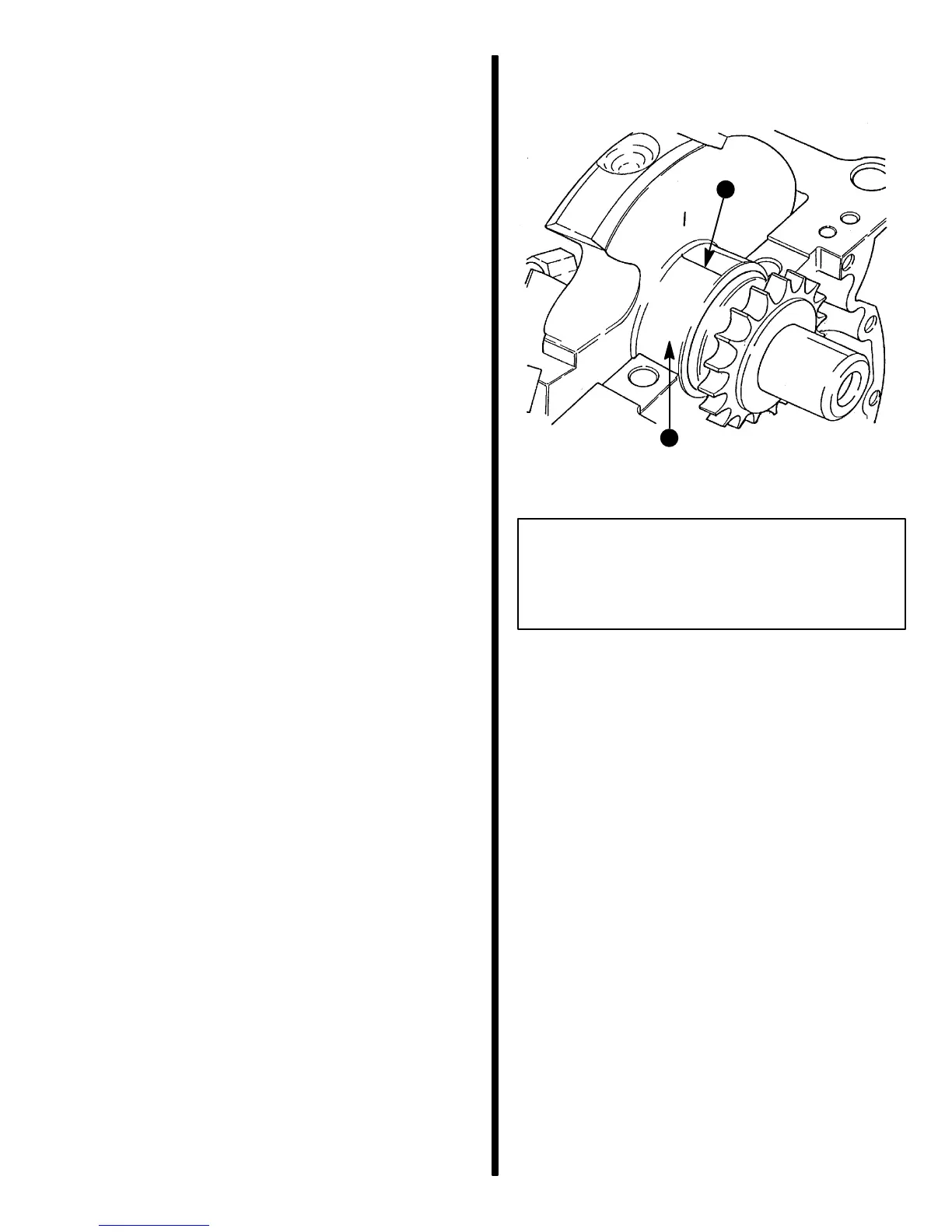

NOTICE

Do not rotate the crankshaft while the

gauging plastic is between the bearing and

journal.

3. Install the bearing cap and evenly torque the re-

taining bolts to specifications. Bearing cap MUST

be torqued to specification in order to assure

proper reading. Variations in torque affect the

compression of the plastic gauge.

4. Remove bearing cap. The flattened gauging

plastic will be found adhering to either the bearing

cap or journal.

Loading...

Loading...