4A-2 - STARTING SYSTEM 90-823225--1 1096

Direct Drive Starter Motor

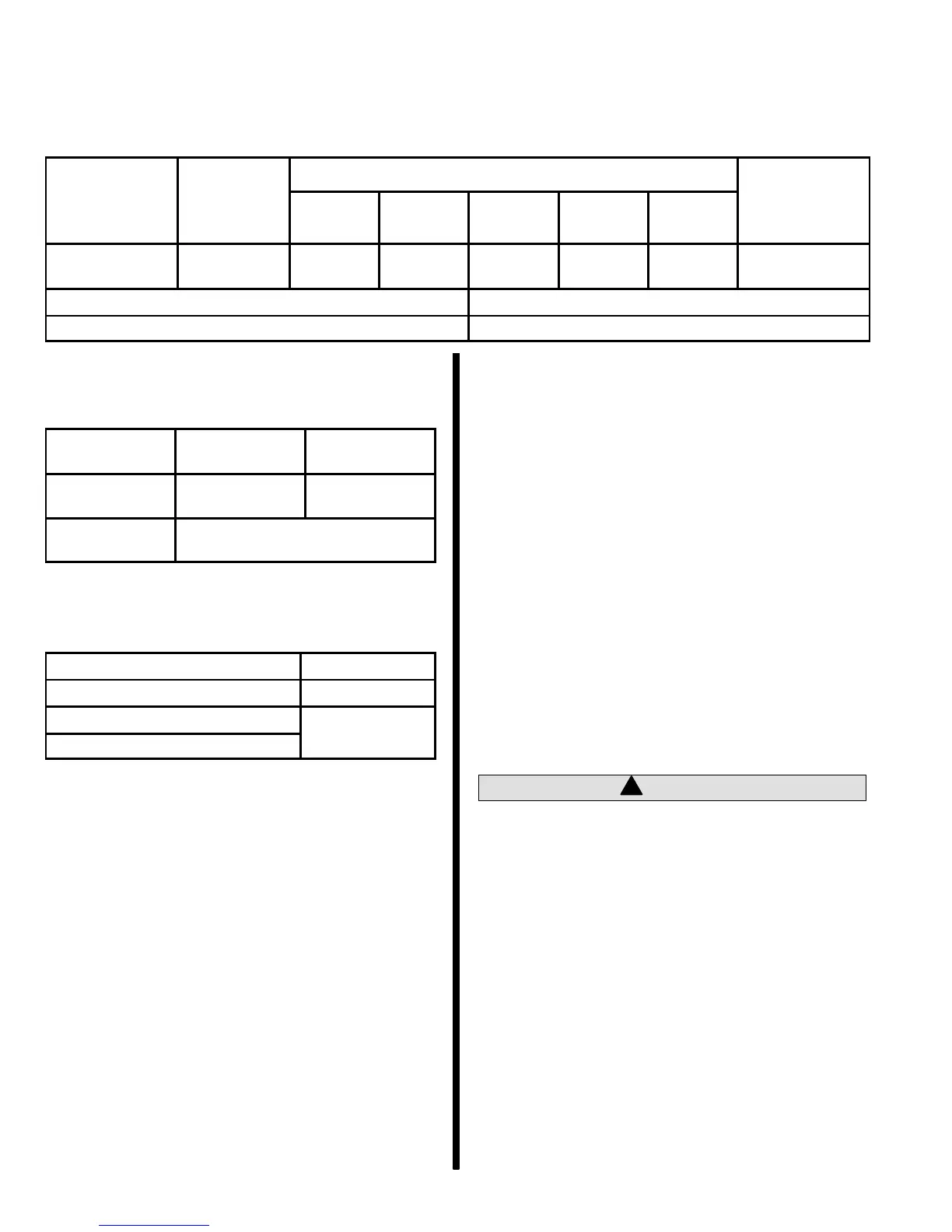

Specifications

Delco

No Load Test

Brush

-

Identification

Number

Rotation

Volts

Min.

Amps

Max.

Amps

Min.

RPM

Max.

RPM

-

sion

Oz. (Grams)

10455602 LH 10.6 70 120 5400 10800

56-105

(1588-2976)

Pinion Clearance .010-.140 (0.25-3.5 mm)

Commutator End Frame Gap .025 Max. (0.6 mm Max.)

Torque Specifications

Fastener

Location

Lb. Ft. N·m

Starter Motor

To Block

50 68

All Other

Fasteners

Tighten Securely

Lubricants/Sealants

Description Part Number

Quicksilver Liquid Neoprene 92-25711-2

SAE 10W Oil

SAE 20W Oil

Positive Current Flow

This is a general description of the positive current

flow, from the battery and through the system until the

starter motor cranks.

• Battery to the solenoid switch (on starter)

(RED battery cable).

• Solenoid switch to circuit breaker (RED).

• Circuit breaker to wire junction (RED-PUR).

• Wire junction to wiring harness plug

(RED-PUR) terminal 6.

• Wiring harness plug to 20 amp fuse

(RED-PUR).

• 20 amp fuse to ignition switch terminal I

(RED-PUR). At this point ignition switch is

turned to START.

• Ignition switch terminal B to terminal S.

• Ignition switch terminal S to neutral start

switch (YEL-RED). NEUTRAL START SWITCH

MUST BE AT NEUTRAL POSITION.

• Neutral start switch to wiring harness plug

terminal 7 (YEL-RED).

• Wiring harness plug to starter solenoid (small

terminal) (YEL-RED). Also ensure that black

(small terminal) wire is grounded.

• Starter solenoid is now “closed,” completing

circuit between large terminal (RED-PUR) and

other large terminal (YEL-RED), causing

starter motor to crank.

!

CAUTION

The starter motor is designed to operate under

great overload and produce a high horsepower

for its size. It can do this only for a short time,

since considerable heat accumulates and can

cause serious damage. For this reason, the

cranking motor must never be used for more than

30 seconds at any one time. Cranking should not

be repeated without a pause of at least 2 minutes

to permit the heat to escape.

Loading...

Loading...