4D-4 - INSTRUMENTATION 90-823225--1 1096

Cruiselog Meter

TESTING

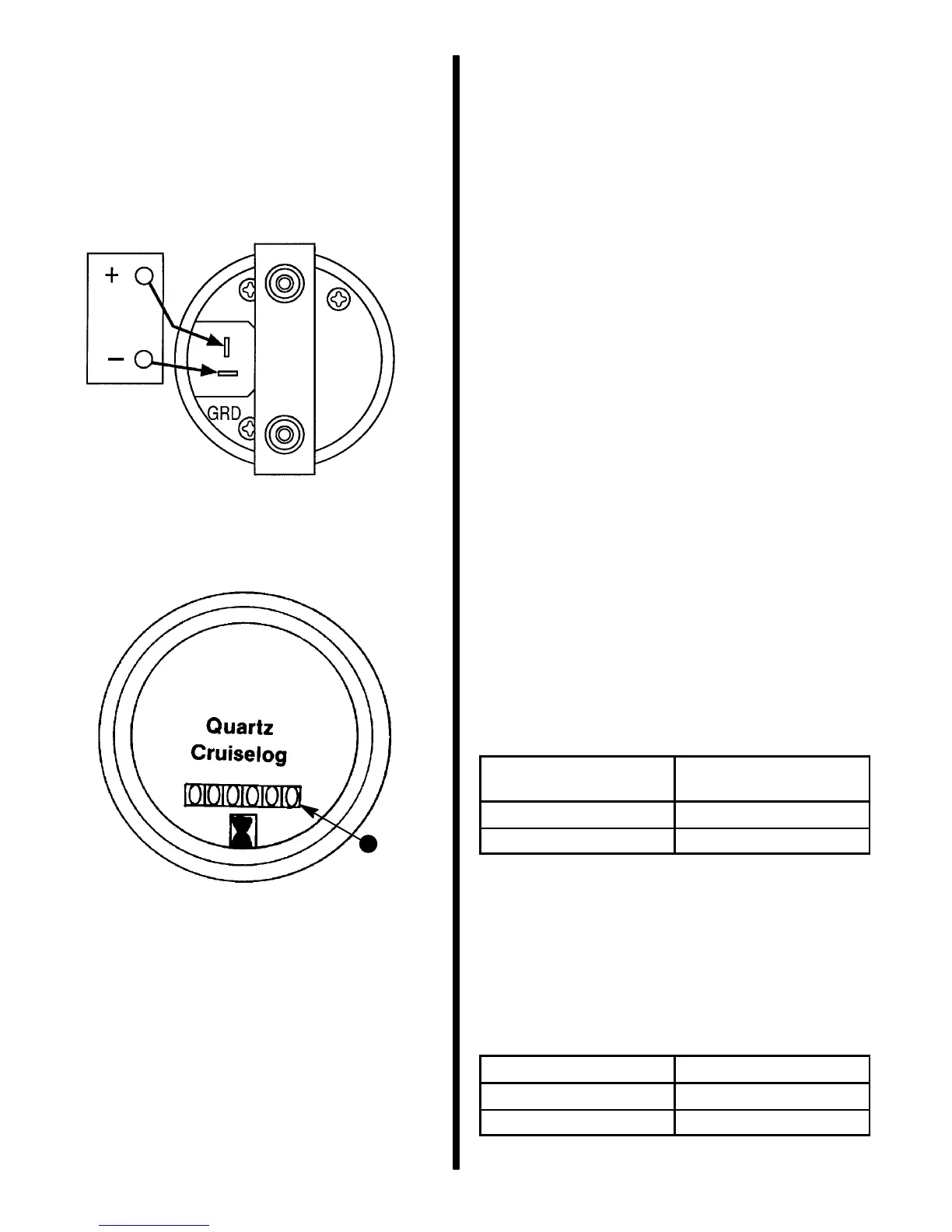

1. Connect jumper wire from negative (–) battery

terminal to negative (–) gauge terminal.

2. Connect jumper wire from positive (+) battery ter-

minal to positive (+) gauge terminal.

72752

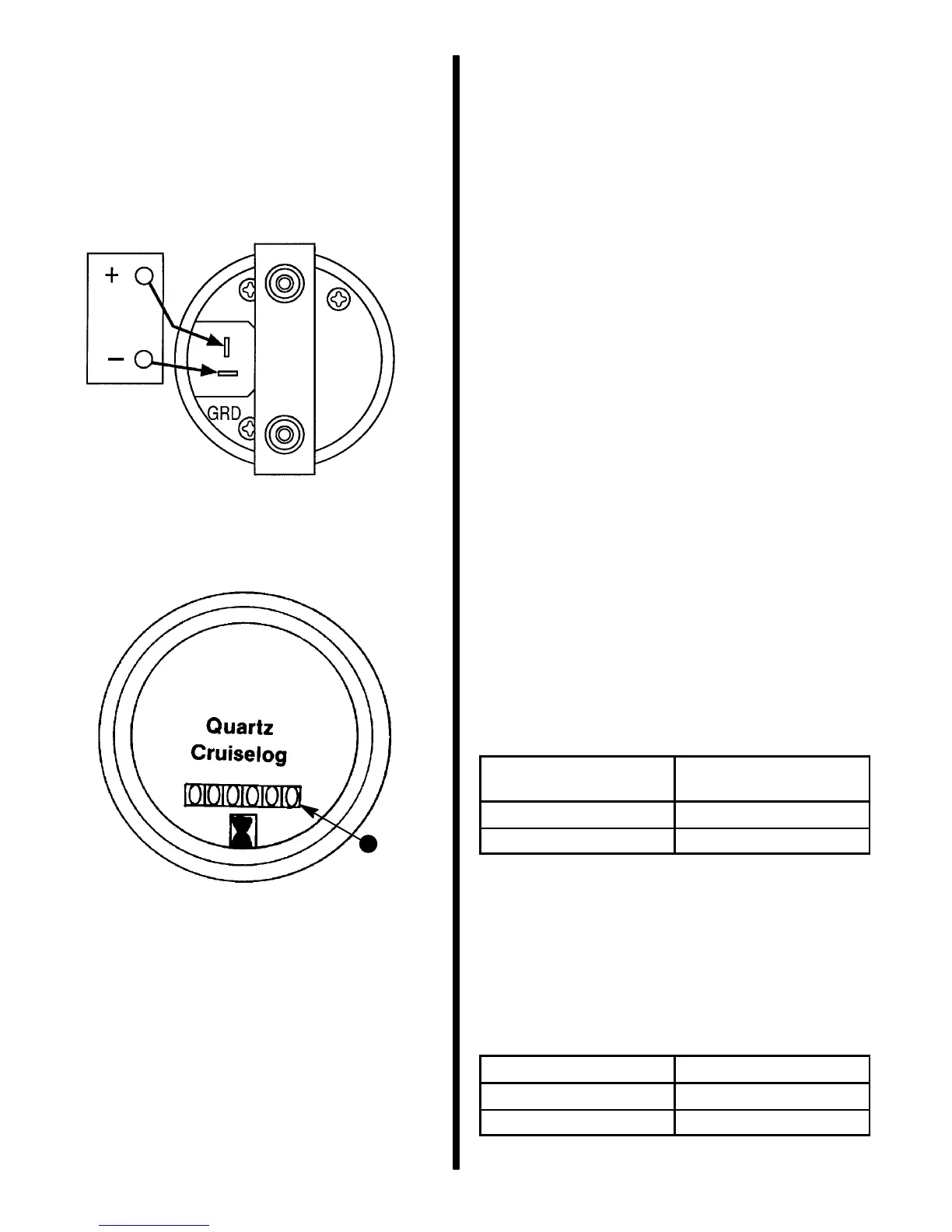

3. Observe gauge run indicator. If indicator is turn-

ing, gauge is operable; if not, replace gauge.

72753

a

a - Indicator

Vacuum Gauge

TESTING

1. Disconnect vacuum hose from engine. Connect

service vacuum gauge to engine and record en-

gine vacuum readings at idle, 1000, 2000 and

3000 RPM. Reconnect vacuum hose and com-

pare vacuum gauge readings (at specified RPM)

with service gauge readings. Readings should be

within 3 inches of vacuum of each other.

IMPORTANT: Make sure that vacuum hose be-

tween gauge and engine is not leaking and that

all connections are tight.

Speedometer

TESTING

IMPORTANT: When testing speedometer gauge

for accuracy, the air supply used for the test must

be regulated to the specified air pressure. Do not

apply excessive air pressure to speedometer

gauge.

1. Apply air pressure directly to speedometer gauge

(specified in chart) and note gauge reading. Light

tapping of pressure gauge is required during ac-

curacy check.

2. If gauge readings are not within specifications,

gauge is defective.

CALIBRATION CHART

Air Pressure Guage

PSI

Speedometer Gauge

MPH (km/Hr)

5.3 20±2 (32±1.6)

27.8 45±1 (72±1.6)

Tachometer

TESTING

1. Connect a service tachometer to engine and

compare readings.

2. Replace if not within specifications.

Tachometer Allowance

6000 RPM ± 150 RPM

8000 RPM ± 200 RPM

Loading...

Loading...