90-823225--1 10965E-82 - ELECTRONIC FUEL INJECTION (MULTI-PORT AND THROTTLE BODY)

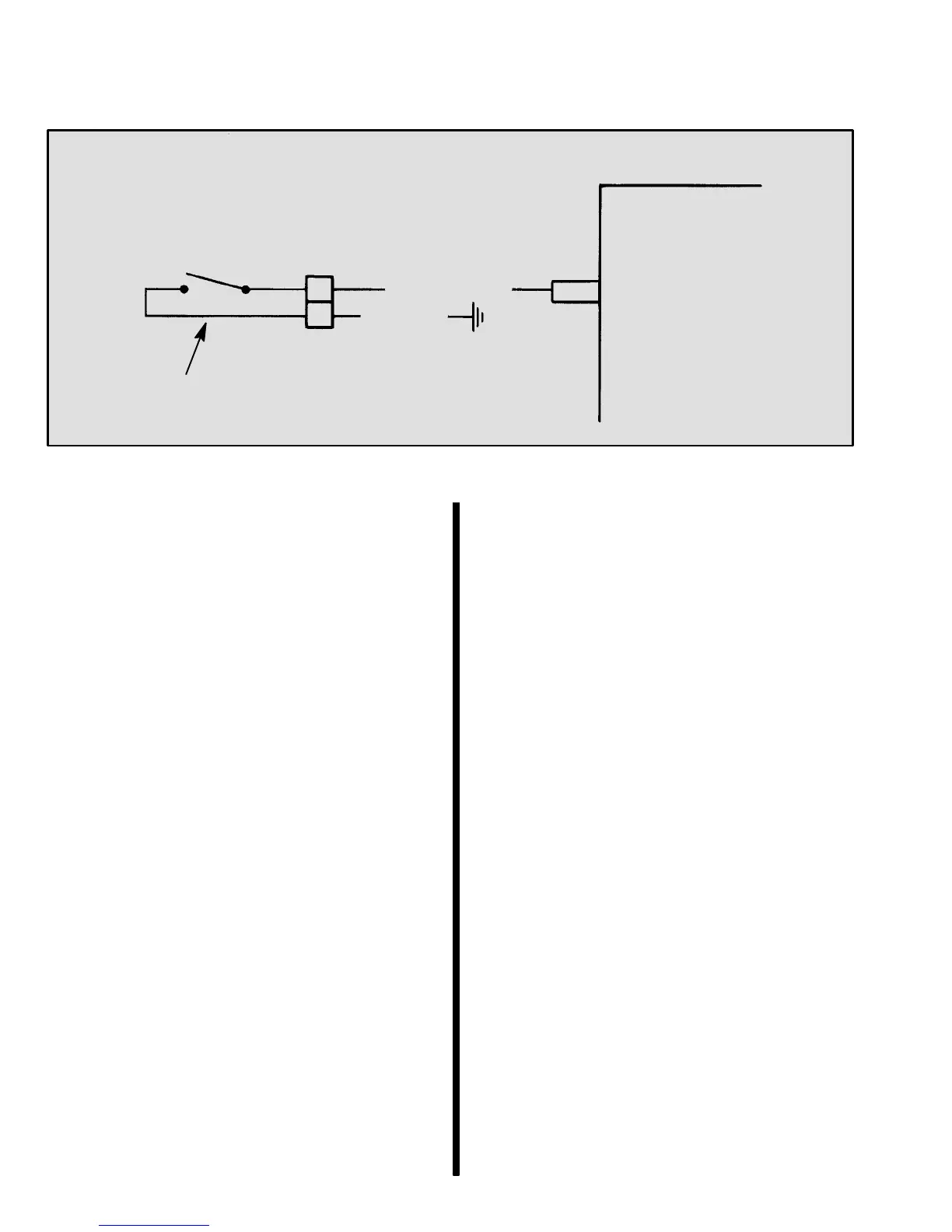

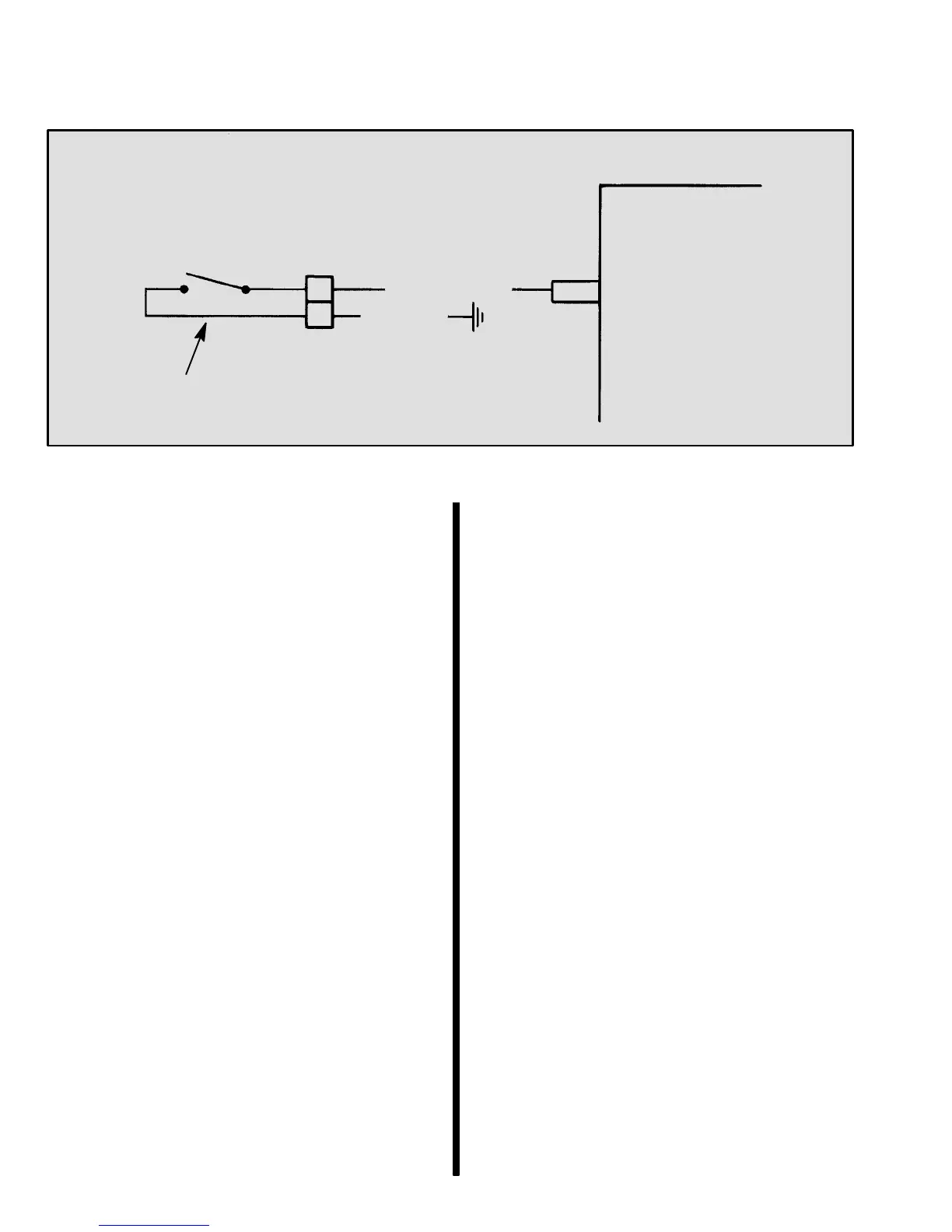

Lanyard Stop Circuit Check (Emergency Stop) Circuit Check

(1 of 2)

IN LINE 2 WAY

CONNECTOR

NORMALLY

OPEN

A

B

BLK

942 PNK

J1-21

ECM

LANYARD STOP SWITCH

LANYARD STOP SWITCH CIRCUIT

1996 AND EARLIER MODELS

NOTE: Some models are no longer equipped with

this option in the wiring harness. Connection of the

lanyard stop switch (if equipped) is performed at the

instrument panel.

CIRCUIT DESCRIPTION:

The Lanyard Stop circuit is a safety feature incorpo-

rated in boats to stop the engine in the event that the

operator is removed from a safe control position dur-

ing normal operation. The Lanyard Stop switch is a

normally open switch that is physically connected to

the operator by a tether. In the event that the operator

is removed from a control position, the tether con-

nected to the switch will be pulled out, closing the

switch. This information from the Lanyard Stop

switch will then be used by the ECM to cease engine

operation until the position of the switch is restored

to its normally open position and the ignition key

switch has been cycled.

TEST DESCRIPTION:

1. If a Lanyard Stop was recognized by the ECM,

cycling the ignition will clear the Lanyard Stop

condition in the ECM.

2. This step checks to see if the Lanyard Stop switch

is in the correct position. If the switch is closed, a

Lanyard Stop condition will exist.

3. This step checks for Lanyard Stop switch or Lan-

yard Stop circuitry that is shorted to ground.

4. This step identifies which half of the circuitry is

shorted to ground; i.e., ECM side or switch side.

5. This step identifies if the circuitry or ECM is the

cause of the short to ground.

DIAGNOSTIC AIDS:

An intermittent problem may be caused by a poor or

corroded connection, rubbed through wire connec-

tion, a wire that is broken inside the insulation, or a

corroded wire.

Any circuitry that is suspected as causing the inter-

mittent complaint should be thoroughly checked for

backed-out terminals, improper mating, broken

locks, improperly formed or damaged terminals, poor

terminal-to-wiring connections, corroded terminals

and/or wiring, or physical damage to the wiring har-

ness.

Loading...

Loading...