3A-52 - ENGINES 90-823225--1 1096

Installation

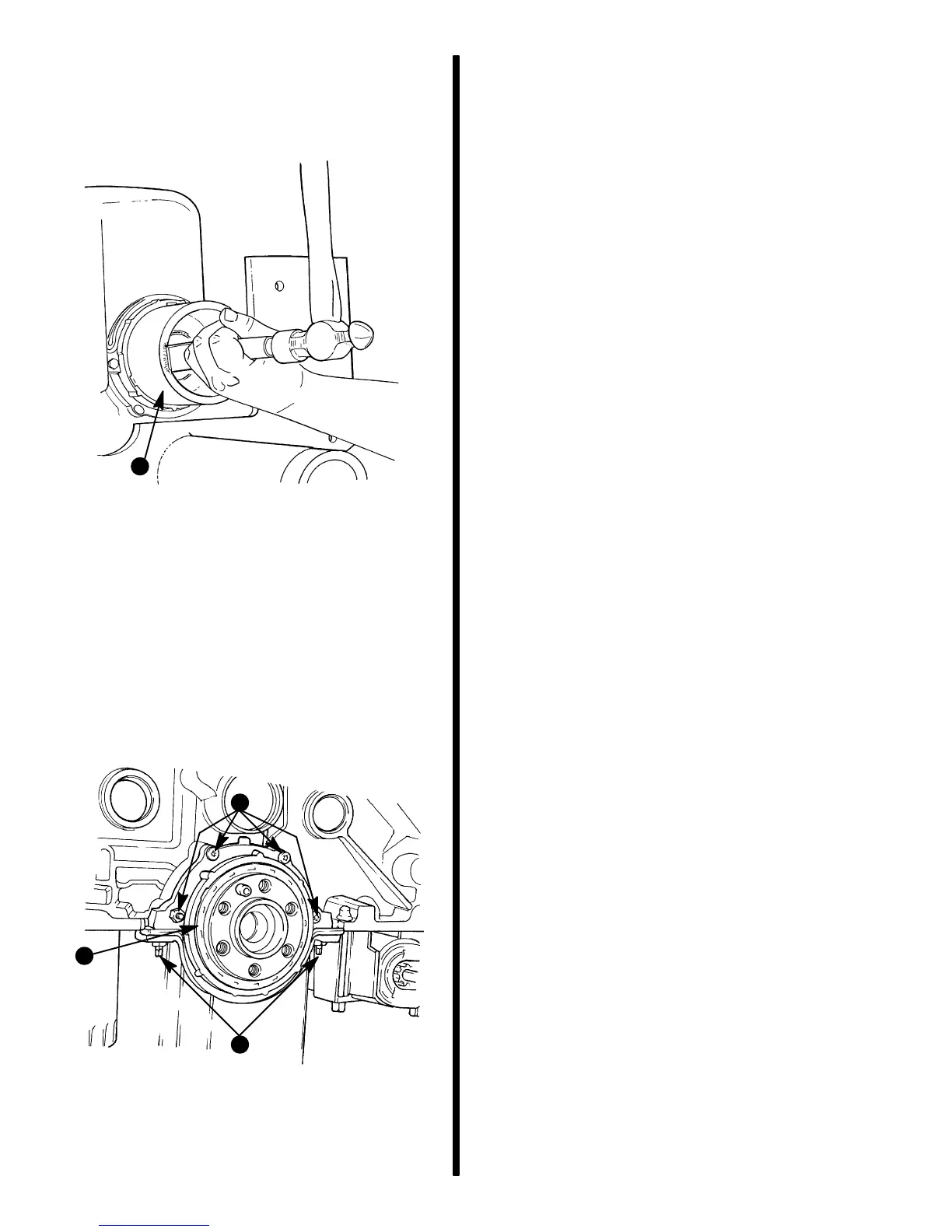

1. Apply Quicksilver Perfect Seal to seal retainer

mating surface. Apply grease to seal lips.

2. Install seal using rear main seal installer.

72356

a - Rear Main Seal Installer (J-26817-A)

a

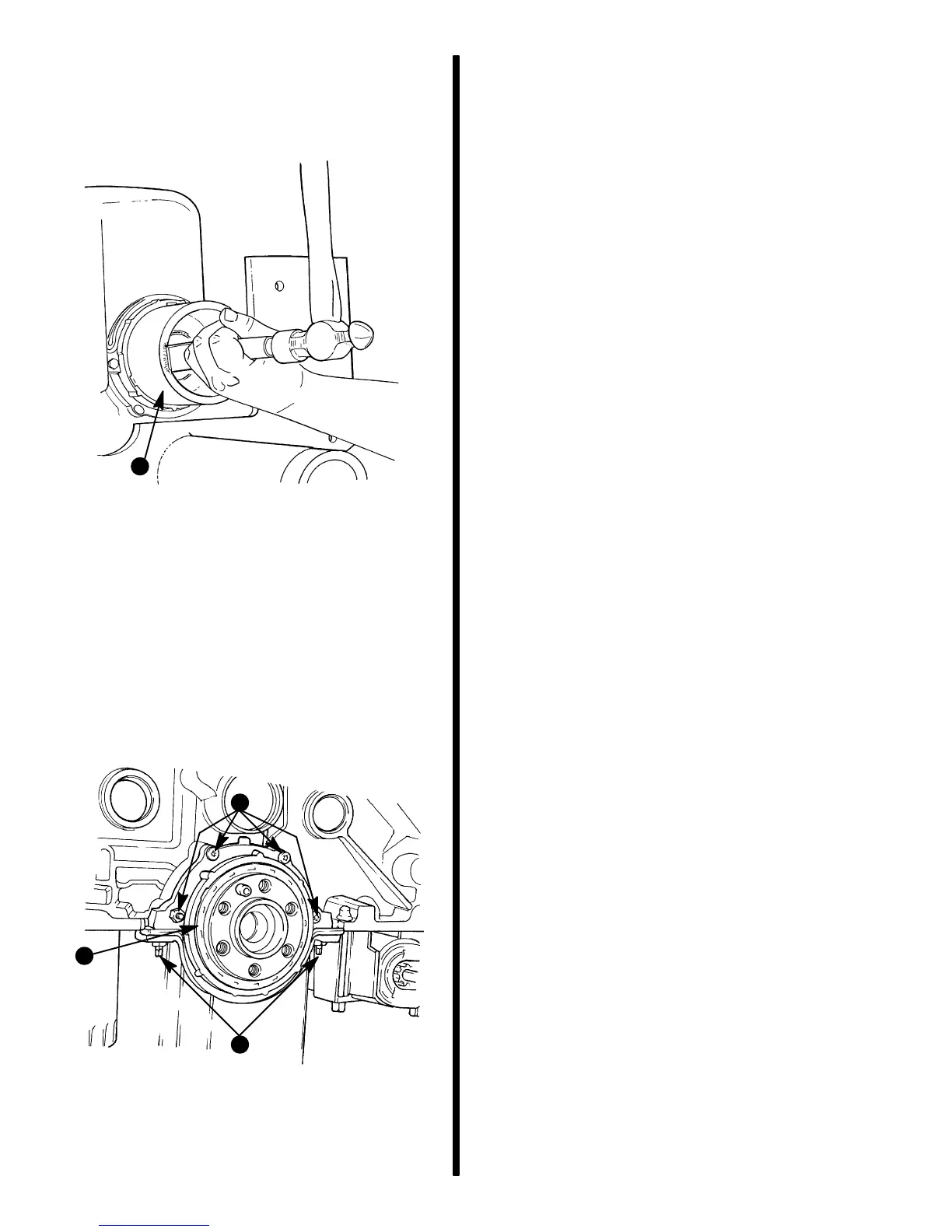

Rear Main Oil Seal Retainer

Removal

1. Remove oil pan.

2. Remove oil seal retainer fasteners.

3. Remove oil seal retainer.

72464

a - Fasteners

b - Oil Seal Retainer

b

a

a

Cleaning and Inspection

1. Clean gasket material from mating surfaces.

2. Inspect oil seal retainer for cracks or scored sur-

face.

3. Inspect oil seal for worn, dry or torn rubber. Re-

place if necessary (refer to “Rear Main Oil Seal”

as outlined).

4. Inspect alignment pin for damage; replace if nec-

essary.

Installation

1. Coat seal lips with clean 30W motor oil.

2. Install gasket and oil seal retainer with rear main

seal.

3. Coat threads of oil seal retainer fasteners with

Loctite Pipe Sealant with Teflon.

4. Install fasteners and torque to 133 lb. in. (15

N·m).

5. Install oil pan fasteners. Torque 1/4-20 thd. fas-

teners to 80 lb. in. (9 N·m) and 5/16-18 thd. fas-

teners to 165 lb. in. (19 N·m).

NOTE: A one-piece oil pan gasket may be re-used if

it is still pliable and is not cracked, torn or otherwise

damaged.

Main Bearings

IMPORTANT: Before removing main bearing

caps or connecting rod caps, mark them for reas-

sembly in their original locations.

Main bearings are of the precision insert type and do

not use shims for adjustment. If clearances are found

to be excessive, a new bearing, both upper and lower

halves, will be required. Service bearings are avail-

able in standard size and .001 in., .010 in. and .020

in. undersize.

Selective fitting of both rod and main bearing inserts

is necessary in production in order to obtain close tol-

erances. For this reason you may find one half of a

standard insert with one half of a .001 in. undersize

insert which will decrease the clearance .0005 in.

from using a full standard bearing.

Loading...

Loading...