3A-38 - ENGINES 90-823225--1 1096

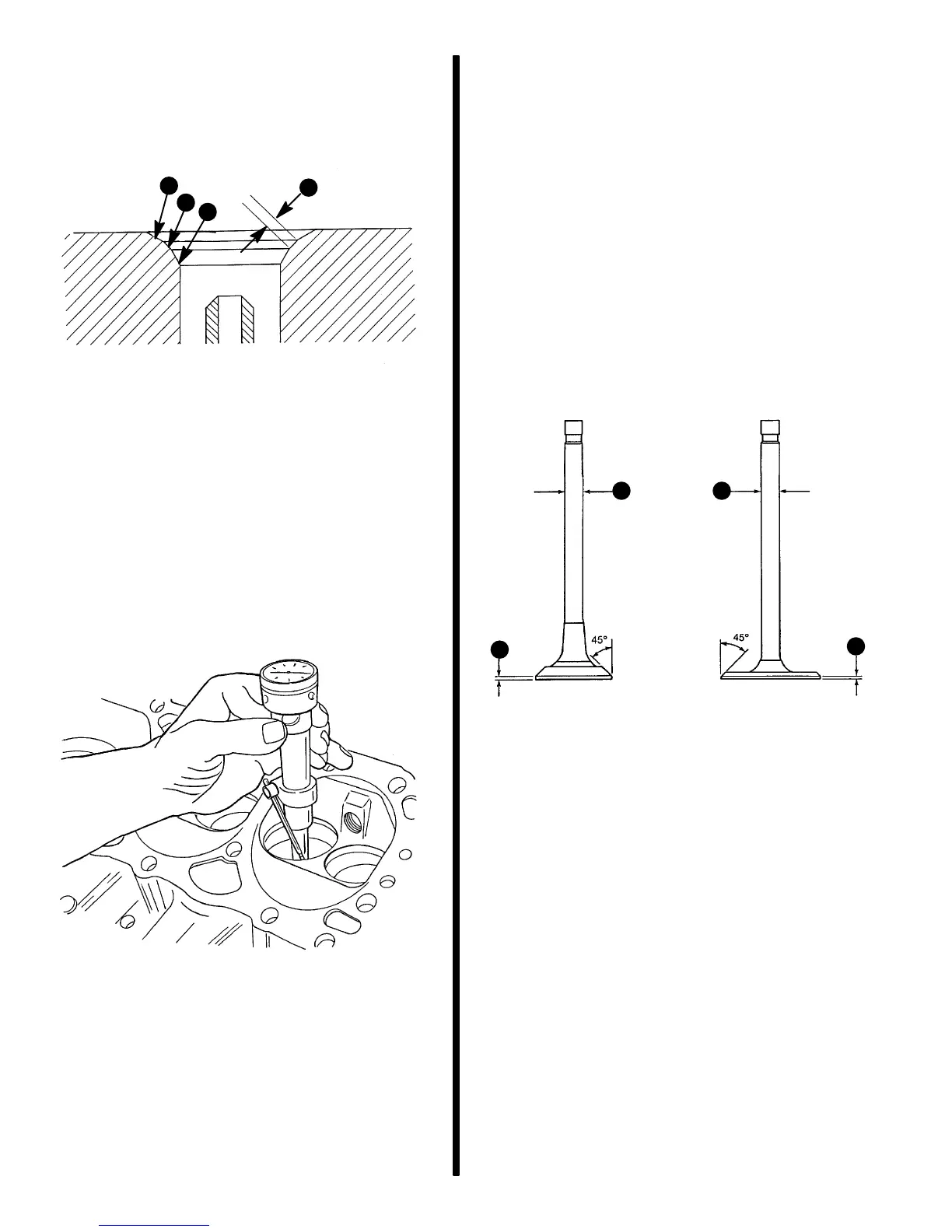

Several different types of equipment are available for

reseating valve seats. Equipment manufacturer’s

recommendations should be followed carefully to at-

tain proper results.

50668

a - Top Angle (30°)

b - Seat Angle (46

°)

c - Bottom Angle (60

°)

d - Seat Width

Intake 1/32-1/16 [.031-.063] In. (0.8-1.5 mm)

Exhaust 1/16-3/32 [.063-.094] In. (1.6-2.3 mm)

Typical “3 Angle” Valve Seat

b

c

d

a

Regardless of type of equipment, however, it is es-

sential that valve guide bores be free from carbon or

dirt to achieve proper centering of pilot in valve guide,

ensuring concentricity.

72338

Measuring Valve Seat Concentricity

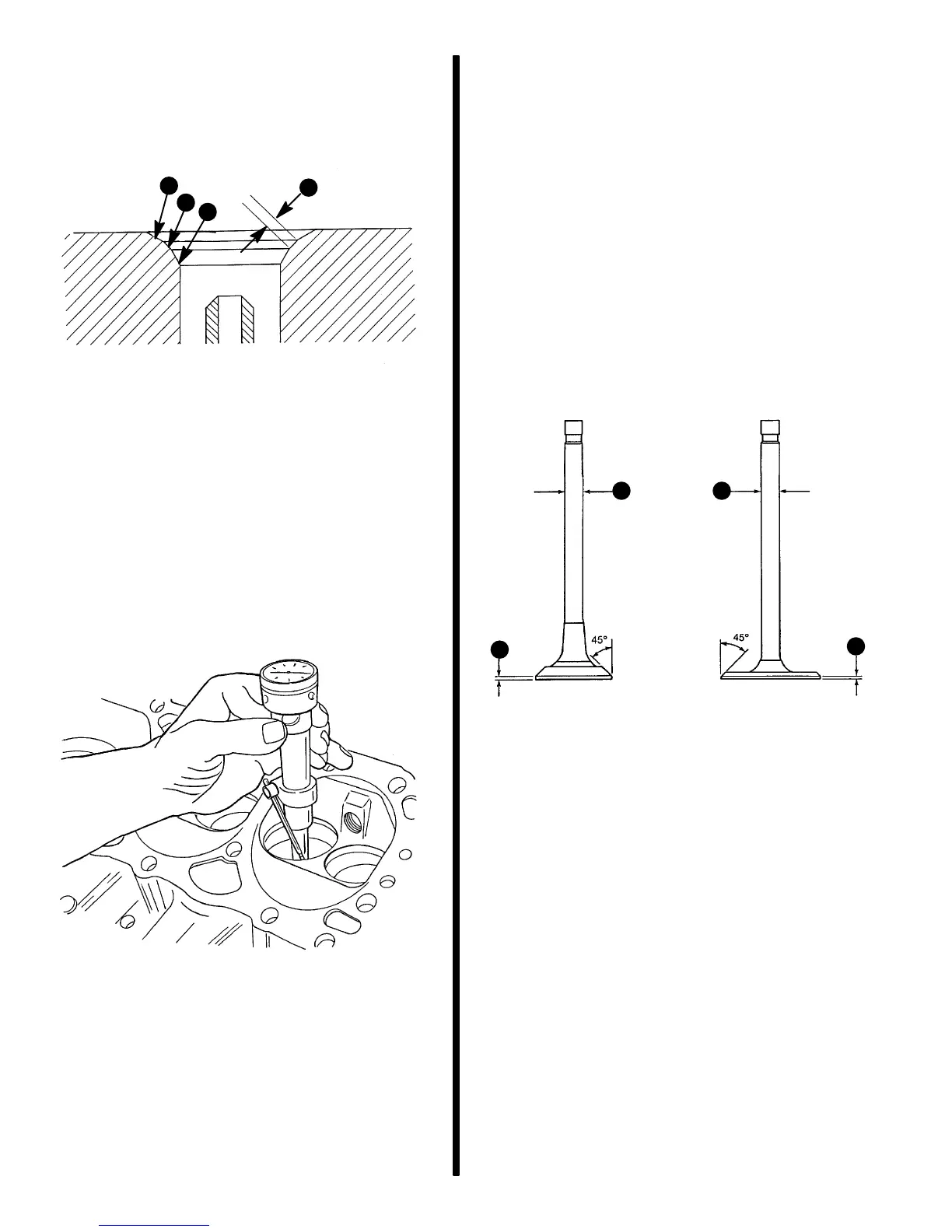

Valve Grinding

Valves that are pitted must be refaced to the proper

angle. Valve stems which show excessive wear, or

valves that are warped excessively, must be re-

placed. When a valve head which is warped exces-

sively is refaced, a knife edge will be ground on part

or all of the valve head, due to the amount of metal

that must be removed to completely reface. Knife

edges lead to breakage, burning, or pre-ignition due

to heat localizing on this knife edge. If the edge of the

valve head is less than 1/32 in. (0.8 mm) after grind-

ing, replace the valve.

Several different types of equipment are available for

refacing valves. The recommendation of the man-

ufacturer of the equipment being used should be

carefully followed to attain proper results.

50695

EXHAUST

INTAKE

Exhaust

a - .372 In. (9.45 mm)

b - 1/32 [.031] In. (0.79 mm) Min.

Intake

a - .341 In. (8.16 mm)

b - 1/32 [.031] In. (0.79 mm) Min.

b

a

b

a

Reassembly

1. Lubricate valve guides and valve stems with en-

gine oil.

2. Install each valve in the port from which it was re-

moved or to which it was fitted.

3. Install valve guide seal (intake valve only) over

valve stem and push down until seated against

head.

4. Set valve spring (with damper installed) and

shield in place.

Loading...

Loading...