4A-38 - STARTING SYSTEM 90-823225--1 1096

Clearances

PINION CLEARANCE

Pinion clearance must be checked after reassembly

of starter motor.

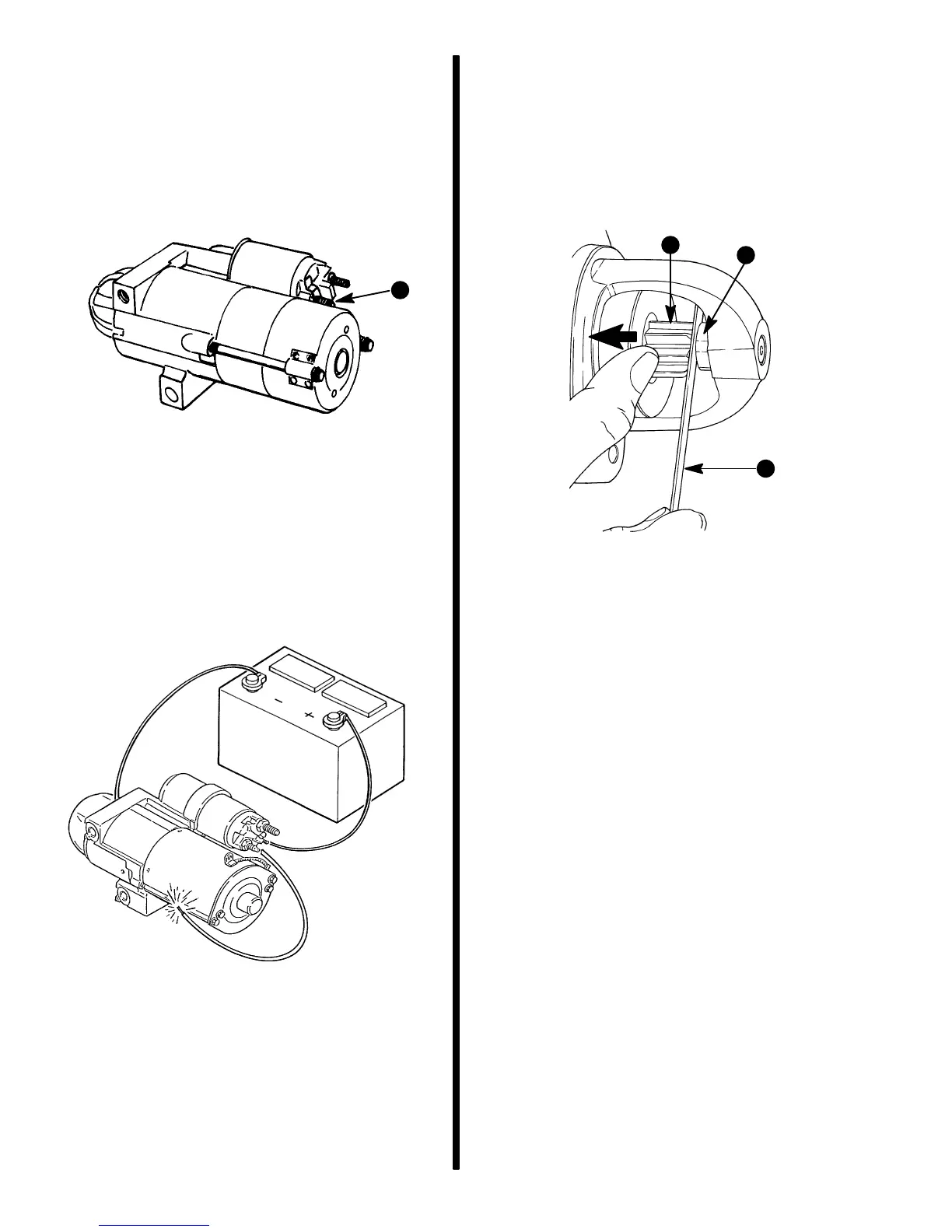

1. Disconnect brush lead from solenoid motor and

insulate it carefully.

74041

a

a - Brush Lead

2. Connect 12 volt battery positive (+) lead to bat-

tery terminal and negative (–) lead to frame.

3. Momentarily touch a jumper lead from battery ter-

minal to switch terminal. This shifts pinion into

cranking position where it will remain until battery

is disconnected.

72629

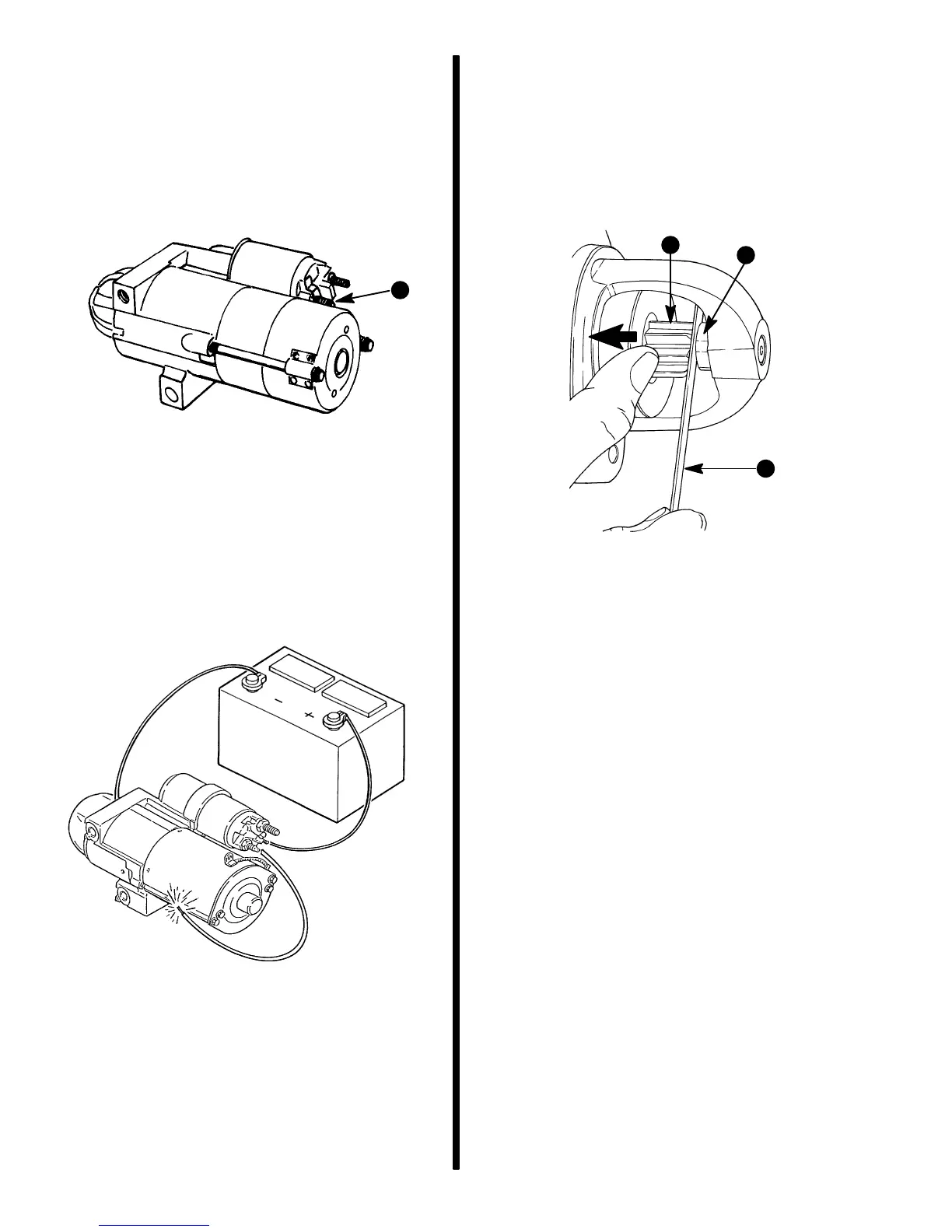

4. Push pinion back toward commutator end to

eliminate slack.

5. Measure distance between pinion and pinion

retainer.

6. If clearance is not within limits of .010-.160 in.

(0.25-4.00 mm), it may indicate excessive wear

of solenoid linkage, shift lever yoke, or improper

assembly of shift lever mechanism. Replace

worn or defective parts, since no provision is

made for adjusting pinion clearance.

72077

b

c

a

a - Pinion

b - Retainer

c - Feeler Gauge

Installation

IMPORTANT: Install special mounting shim (if

equipped) between starter motor and engine

block.

1. Place starter motor in position and install mount-

ing bolts. Torque bolts to 30 lb. ft. (41 N·m).

2. Connect YELLOW/RED wire to terminal S of so-

lenoid. Connect ORANGE wire, RED wire, and

battery cable to large terminal of solenoid. Tight-

en fasteners securely. Coat terminals with Quick-

silver Liquid Neoprene. Install battery cable boot,

if so equipped.

3. Connect battery cables to battery in the following

order. Connect positive (+) cable to positive (+)

battery terminal and tighten cable clamp. Then

connect negative (–) cable to negative (–) termi-

nal and tighten clamp.

Loading...

Loading...