4D-6 - INSTRUMENTATION 90-823225--1 1096

Water Temperature

DUAL STATION SENDER IDENTIFICATION

Sender will have 362-BC stamped on hex.

REMOVAL

1. Drain coolant from closed cooling system into a

suitable container as outlined in Section 6B.

2. Remove TAN wire from temperature sender.

72611

b

a

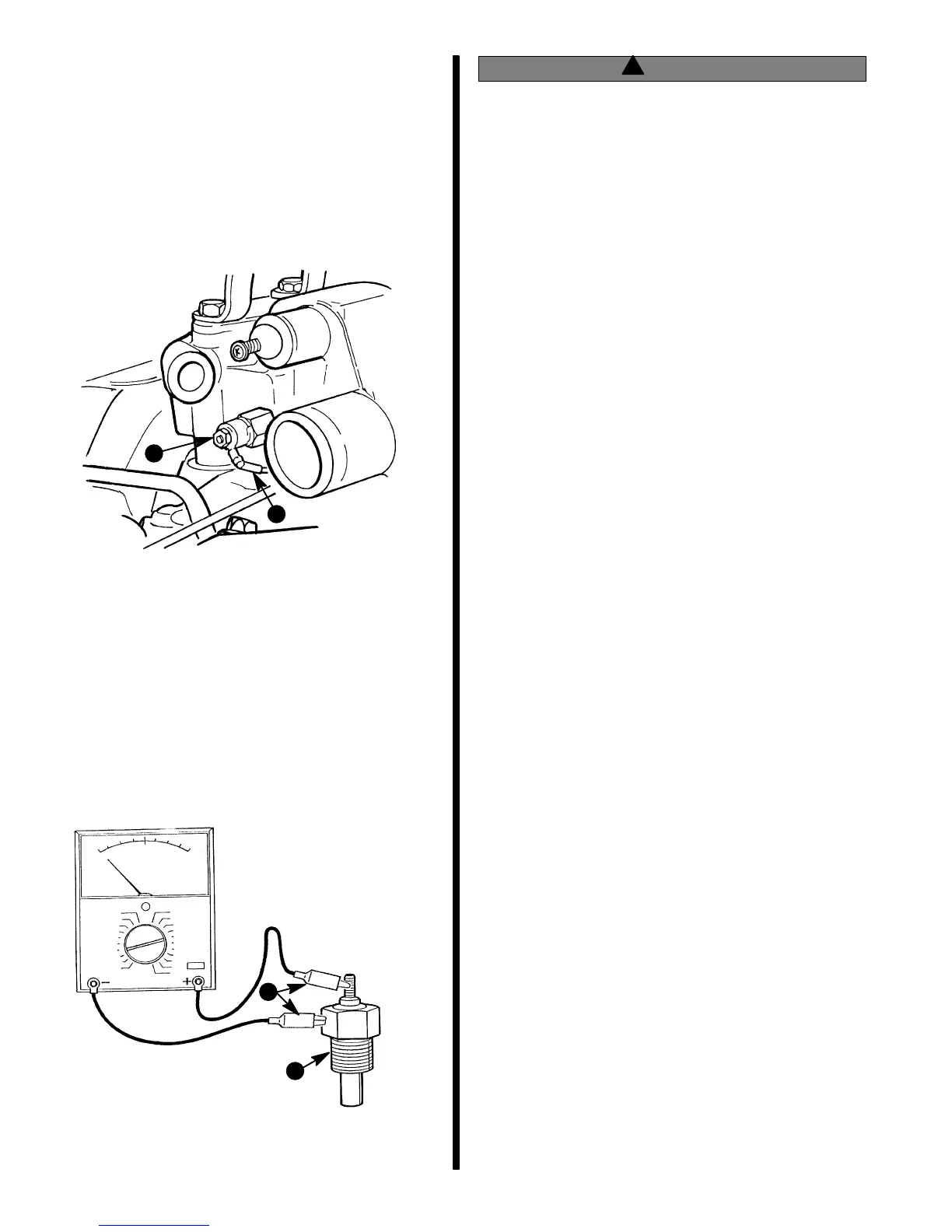

Typical Water Temperature Sender

a - TAN Wire

b - Water Temperature Sender

NOTE: Hoses are shown removed for clarity.

3. Remove temperature sender.

TESTING

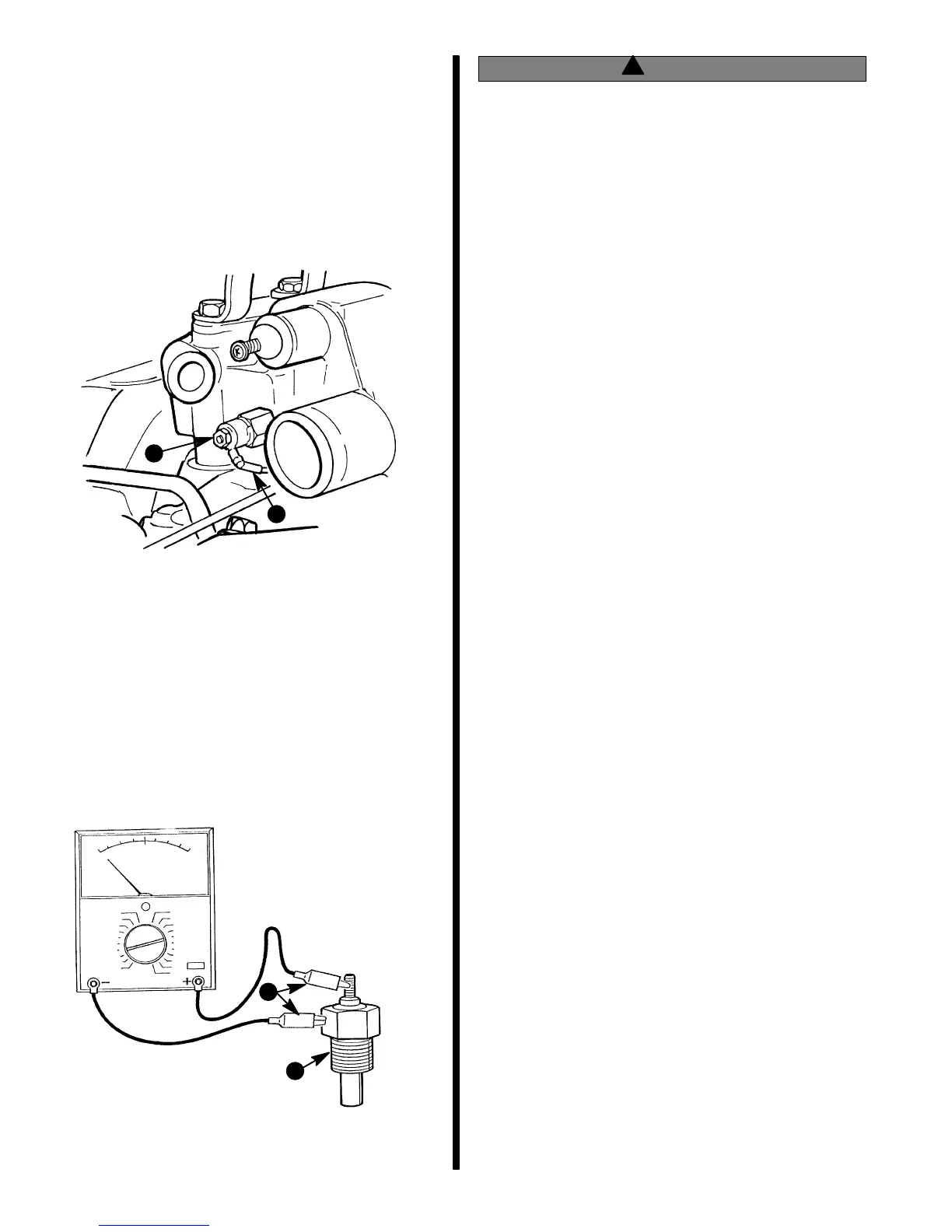

1. Connect an ohmmeter between temperature

sender terminal (+) and hex (case) for ground (–)

as shown.

72768

b

a

a - Ohmmeter Leads

b - Water Temperature Sender

!

WARNING

The following test involves the use of intense

heat. Failure to follow appropriate procedures or

warnings can cause burns which can result in se-

vere personal injury. While performing the fol-

lowing test, observe these general precautions:

• Wear personal protective clothing such as

rubber gloves, a non-flammable apron, and

eye protection - preferably full face shield or

safety glasses.

• The appropriate heat source should only be

electric. Heat source should be operated by a

qualified person. Be sure to follow all instruc-

tions of the manufacturer of the heat source.

The heat source should be checked each time

it is used to be sure it is functioning properly.

• The thermometer used in the test should be a

high-temperature thermometer with a maxi-

mum reading of at least 300°F (150°C). Under

no circumstances should the operator allow

temperatures to exceed test specifications.

• Perform test only in a well ventilated area.

• Use a suitable container, such as metal, to

hold the water. Avoid use of glass containers

unless the operator first confirms for himself/

herself that the glass container is an appro-

priate high-temperature vessel.

• Because the components will reach high tem-

peratures DO NOT handle materials or com-

ponents until COMPLETELY cooled.

Loading...

Loading...