4B-22 - THUNDERBOLT IV AND V IGNITION SYSTEM 90-823225--1 1096

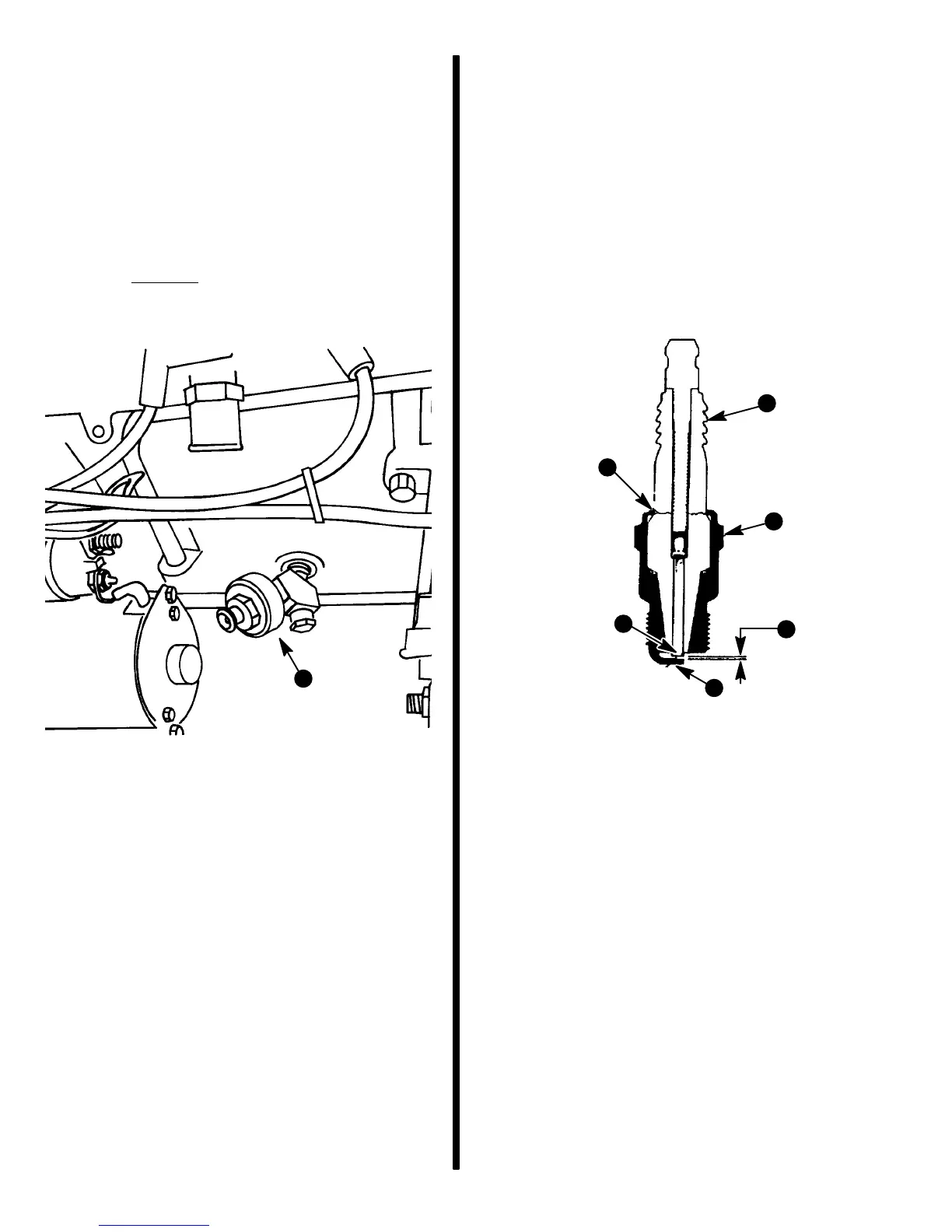

INSTALLATION OF KNOCK SENSOR

IMPORTANT: If installing a new knock sensor, be

sure to replace it with an identical part. Knock

sensors are very sensitive and designed for each

specific application.

IMPORTANT: It is very important that the knock

sensor be torqued to the exact specification. In-

correct torquing will result in unsatisfactory per-

formance. DO NOT

use sealer on threads.

1. Install knock sensor in engine block. Torque to

12-16 lb. ft. (16.3-21.7 N·m).

73756

a

a - Knock Sensor

2. Connect electrical connector to knock sensor.

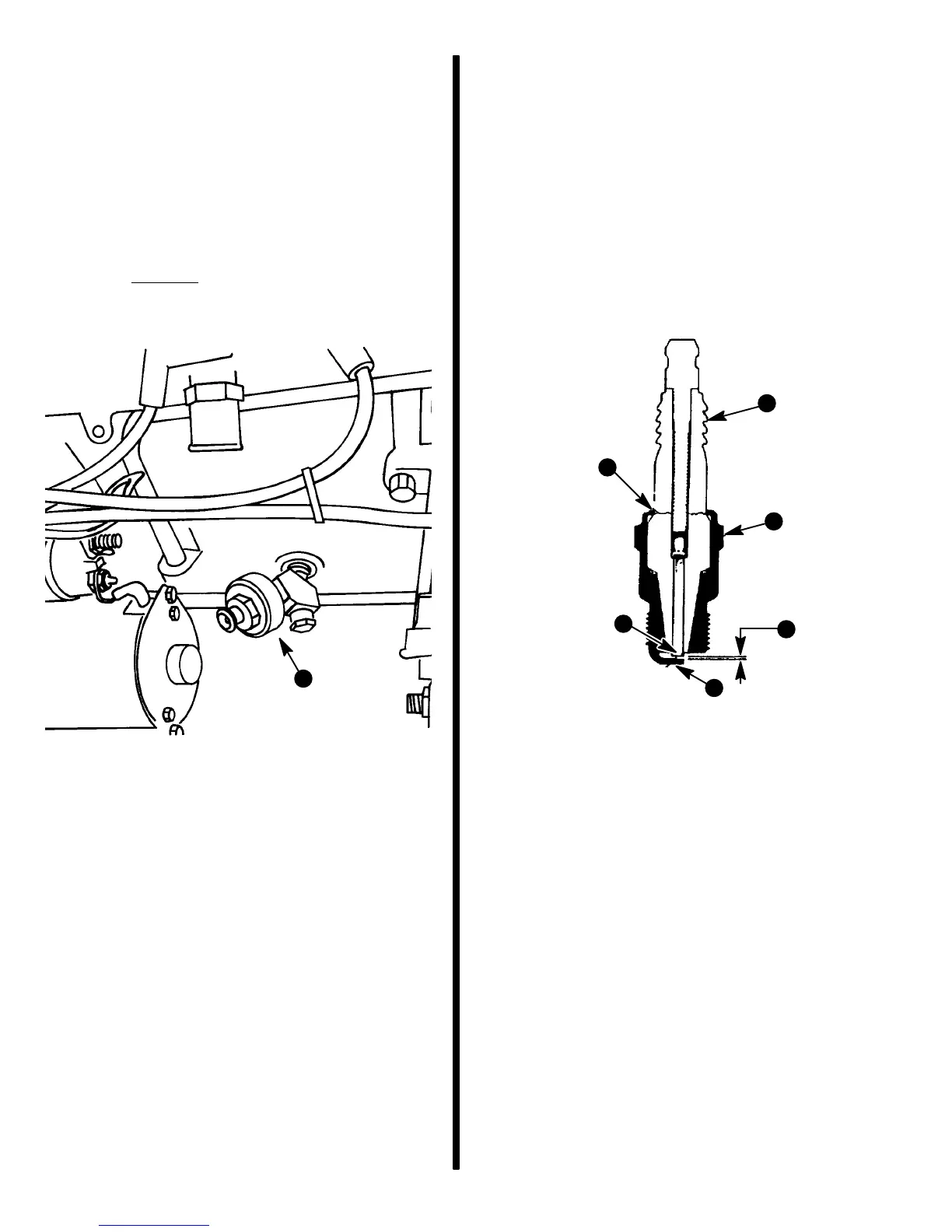

Spark Plugs

1. Inspect each plug individually for badly worn

electrodes, glazed, broken or blistered porcelain

and replace where necessary.

2. Inspect each spark plug for make and heat range.

All plugs must be the same make and number

and heat range. Refer to “Specifications” for

spark plug numbers.

3. Adjust spark plug gaps with a round feeler gauge.

Refer to “Specifications” for proper spark plug

gap.

72734

b

c

d

a

e

f

a - Porcelain Insulator

b - Insulator Cracks Often At This Point

c - Shell

d - Proper Gap

e - Side Electrode (Bend To Adjust Gap)

f - Center Electrode (File When Adjusting Gap - DO NOT

Bend)

4. Clean spark plug seating area. Do not use gas-

kets on taper seat plugs. Install spark plugs and

torque to specifications. Where used, gasket

must be fully compressed to complete heat trans-

fer and provide a gas- tight seal in cylinder. For

this reason, as well as the necessity of maintain-

ing correct plug gap, correct torque is very impor-

tant during installation.

IMPORTANT: Tapered seat spark plugs are not in-

terchangeable with non-tapered (with gasket)

spark plugs.

Loading...

Loading...