2D-4 – MCM MODELS - BRAVO MODELS WITH DRIVE SHAFT EXTENSIONS 90-823225--1 1096

Installation

Engine Installation/Alignment

ENGINE MOUNT ADJUSTMENT WAS NOT

DISTURBED DURING SERVICE

!

CAUTION

Center lifting eye (located on top of thermostat

housing) is used for engine alignment only. DO

NOT use to lift entire engine.

!

CAUTION

DO NOT allow lifting sling to hook or compress

engine components or damage to them will oc-

cur.

1. Attach a suitable sling to lifting eyes on engine

and adjust so that engine is level when sus-

pended. (Refer to “Removal” section for loca-

tion of lifting eyes.)

2. Lift engine into approximate position (in boat),

using an overhead hoist.

3. Set engine on stringers.

4. Grease drive shaft universal joints with Quicksil-

ver 2-4-C Marine Lubricant.

!

CAUTION

When attaching shaft in next step, BE SURE that

the pilot on drive shaft flanges are engaged in in-

put shaft and output shaft flanges. Flanges

MUST BE flush to each other prior to tightening

screws or screws may come loose during opera-

tion.

!

CAUTION

Failure to align shaft flanges with matching

marks made on disassembly may cause improp-

erly aligned drive unit and extension drive shaft

U-joint centerlines resulting in a severe vibration

problem.

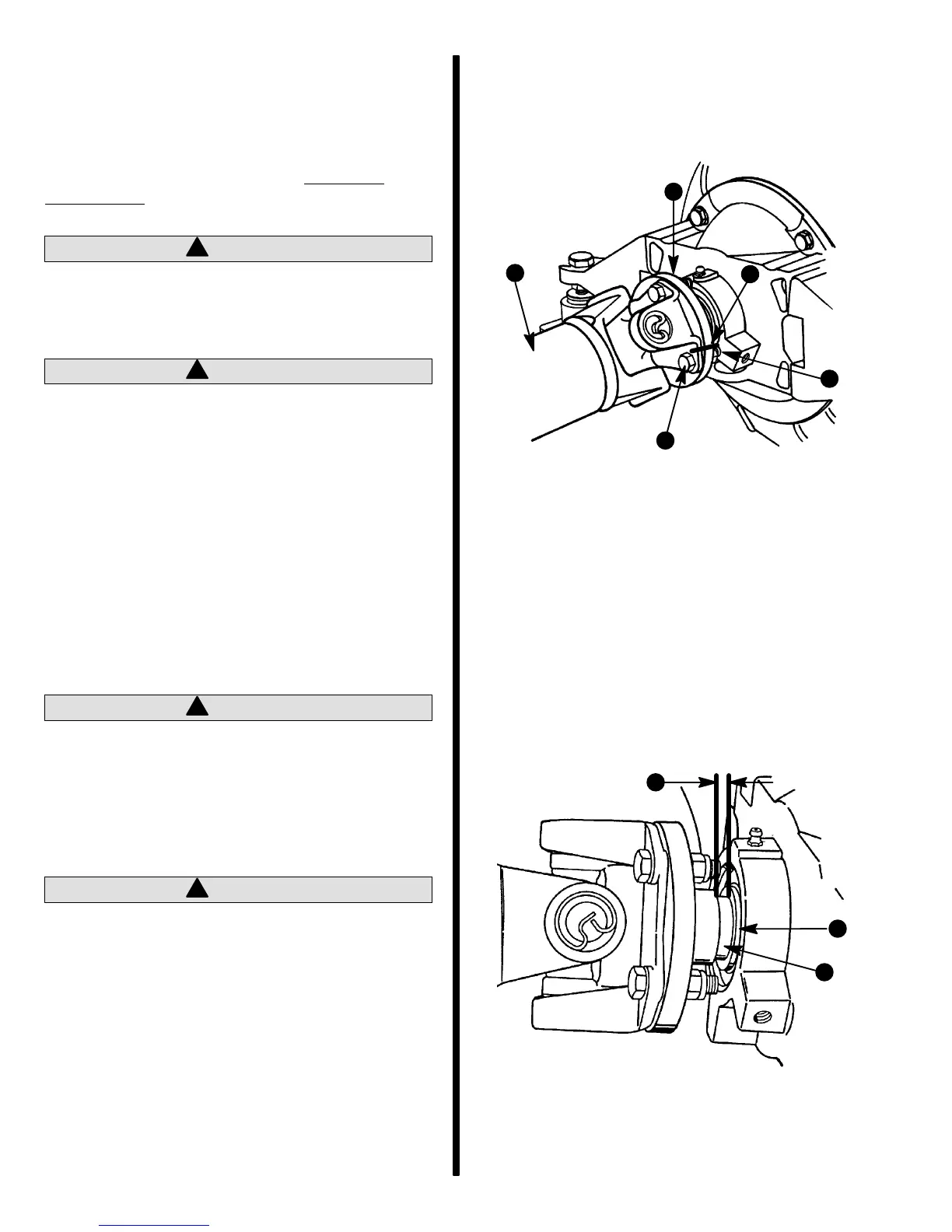

5. As shown, attach engine output flange to drive

shaft flange exactly as marked during disassem-

bly. Torque fasteners to 50 lb. ft. (68 N·m).

70237

b

c

d

a

e

Engine End Shown

a - Output Shaft Flange

b - Drive Shaft

c - Screw

d - Nut

e - Matching Marks Made Upon Disassembly - Aligned

IMPORTANT: Failure to properly position output

shaft flange may result in bearing damage.

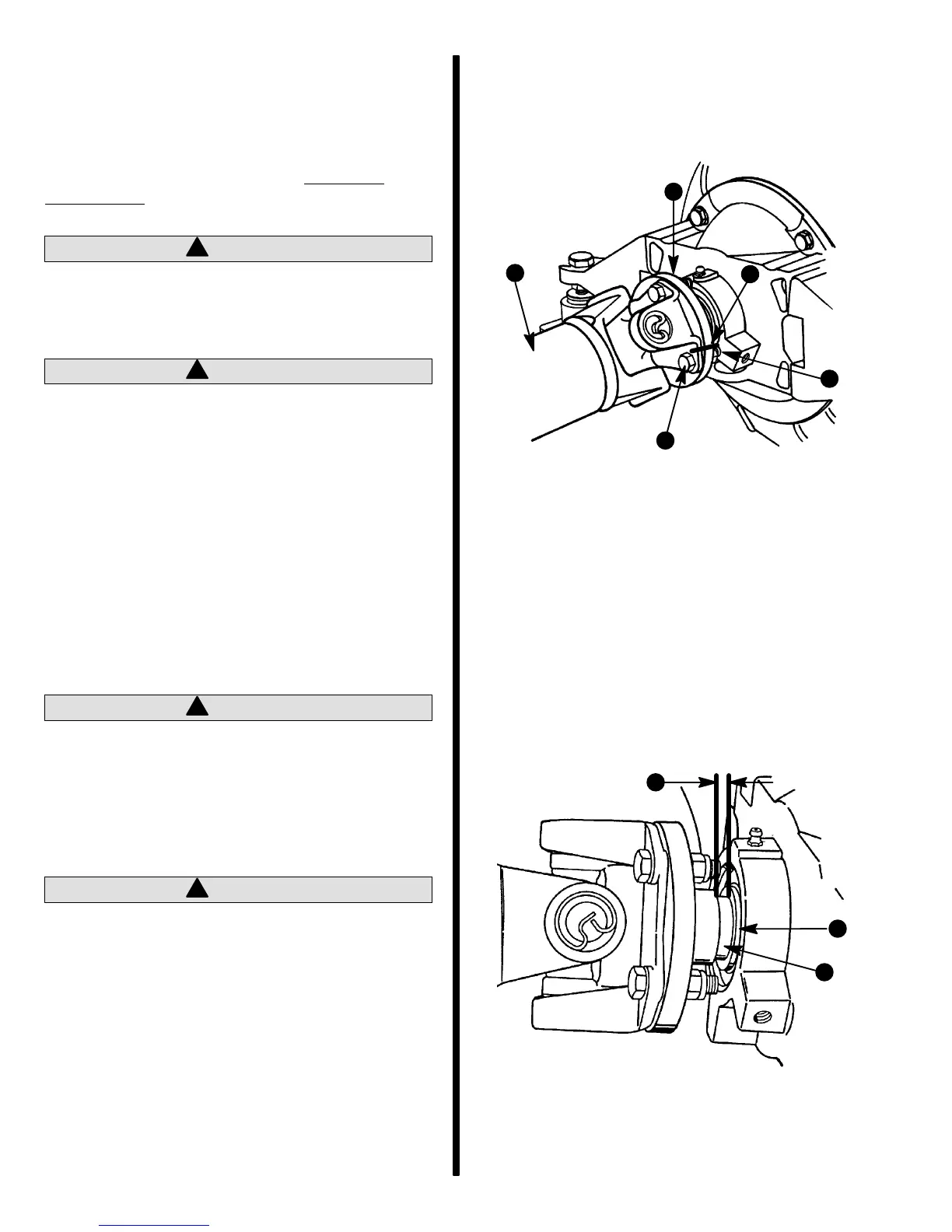

6. Relieve hoist tension from engine, then slide en-

gine fore or aft as needed to obtain 1/4 in. (6 mm)

clearance between flange shoulder and exten-

sion shaft housing bearing.

72591

a - Flange Shoulder

b - Bearing

c - 1/4 In. (6 mm)

b

c

a

Loading...

Loading...