3A-46 - ENGINES 90-823225--1 1096

Torsional Damper

Removal

1. Remove drive belts.

2. Remove drive pulley, then remove torsional

damper retaining bolt.

IMPORTANT: Do not use a universal claw type

puller to remove torsional damper (in next step)

as outside ring of torsional damper is bonded in

rubber to the hub and use of claw type puller may

break the bond.

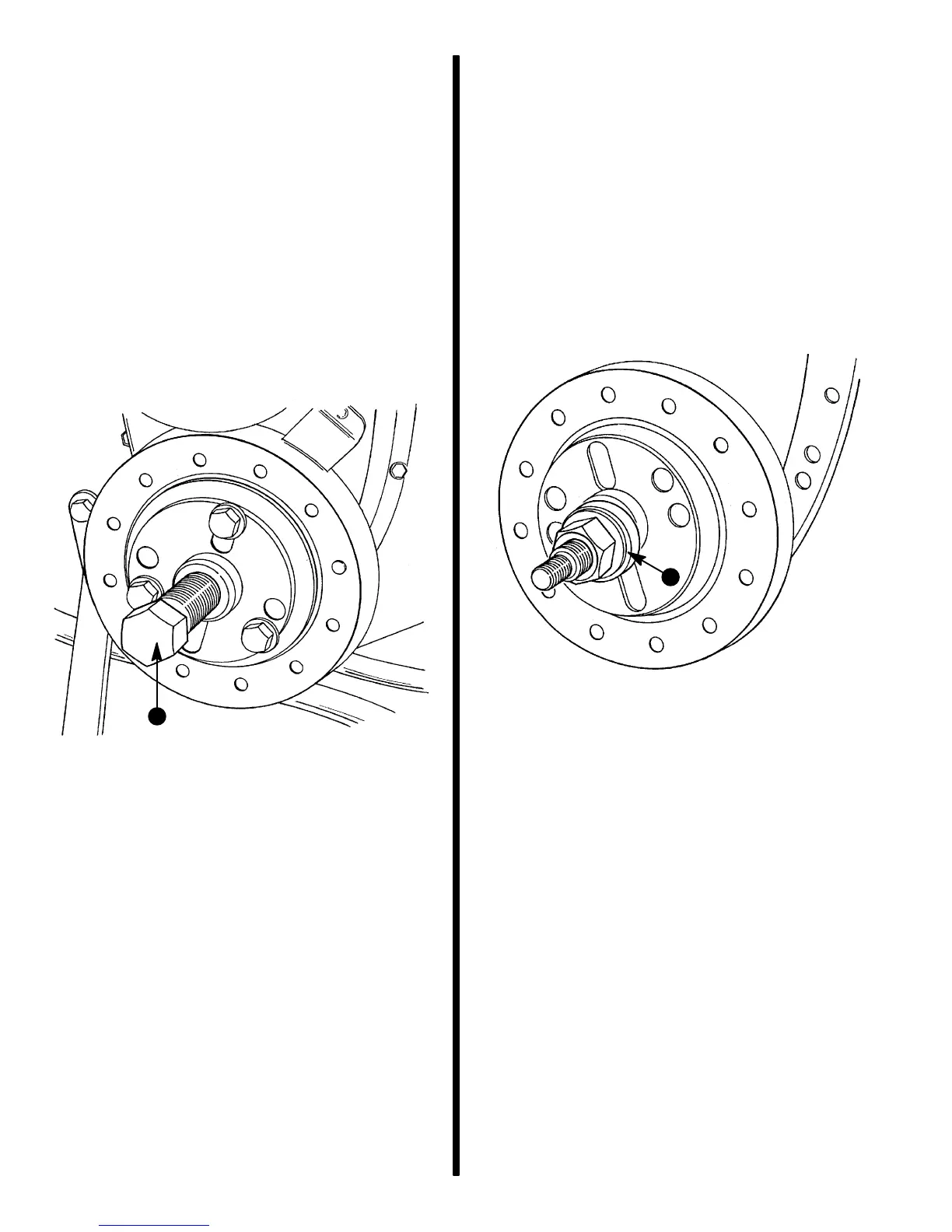

3. Remove torsional damper with torsional damper

remover and installer.

72345

a - Torsional Damper Remover and

Installer (J-23523-E)

a

Installation

IMPORTANT: The inertia weight section of tor-

sional damper is assembled to the hub with a rub-

ber type material. The installation procedure

(with proper tool) must be followed or movement

of the inertia weight on the hub will destroy the

tuning of the torsional damper.

1. Replace key in crankshaft if it is damaged.

2. Coat seal surface of torsional damper with en-

gine oil.

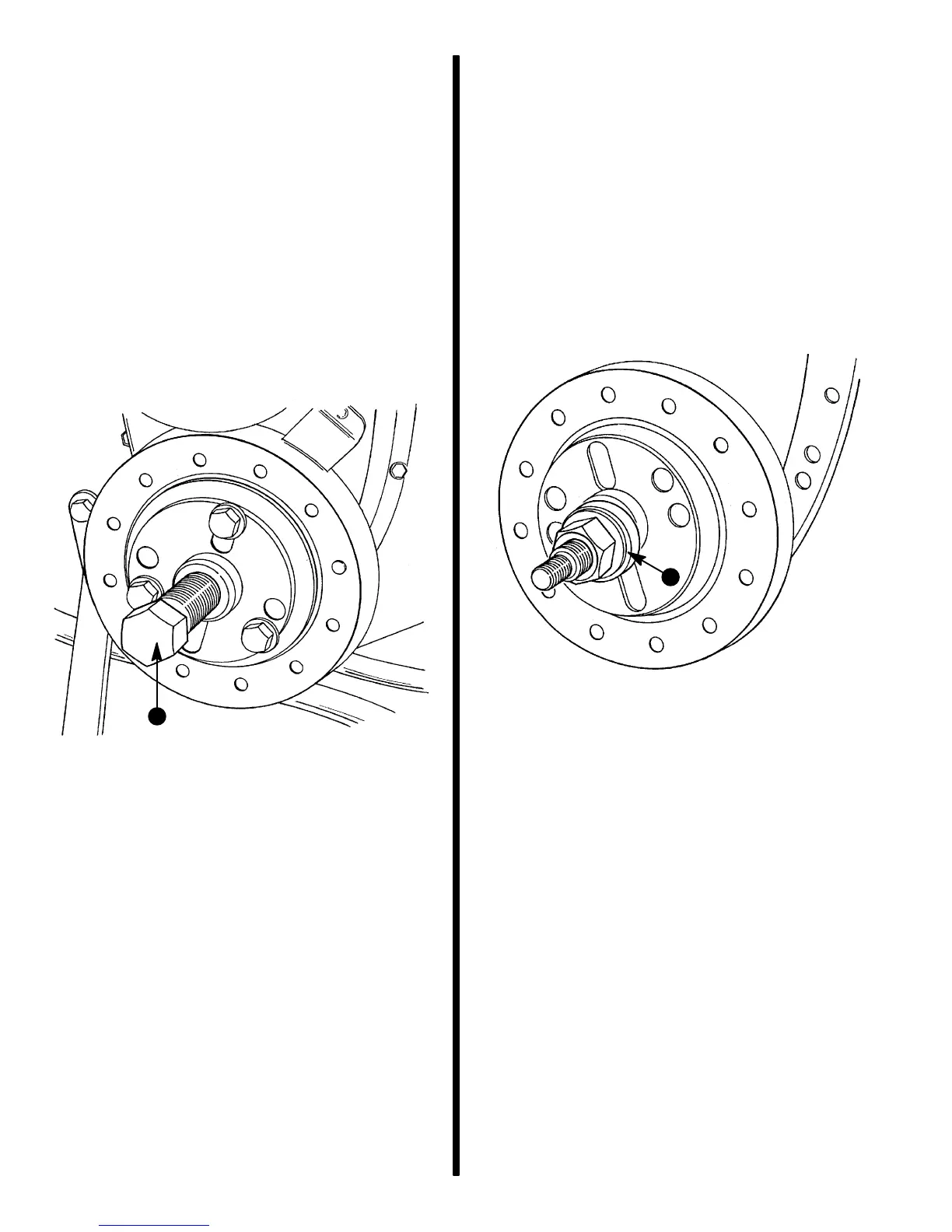

3. Install torsional damper on crankshaft, using tor-

sional damper remover and installer as follows:

a. Install appropriate end of threaded rod into

crankshaft.

IMPORTANT: Be sure to install threaded rod in

crankshaft at least 1/2 in. (13 mm) to prevent dam-

age to threads.

b. Install plate, thrust bearing, washer and nut

on rod.

c. Install torsional damper on crankshaft by

turning nut until it bottoms out.

72346

a - Torsional Damper Remover and Installer

(J-23523-E)

a

d. Remove tool from crankshaft.

e. To prevent oil leakage, apply Quicksilver RTV

sealant to torsional damper keyway.

f. Install torsional damper bolt. Torque to 60 lb.

ft. (81 N·m).

4. Install drive pulley(s). Torque bolts to 35 lb. ft.

(48 N·m).

5. Install and adjust drive belts.

Loading...

Loading...