1B-2 - MAINTENANCE 90-823225--1 1096

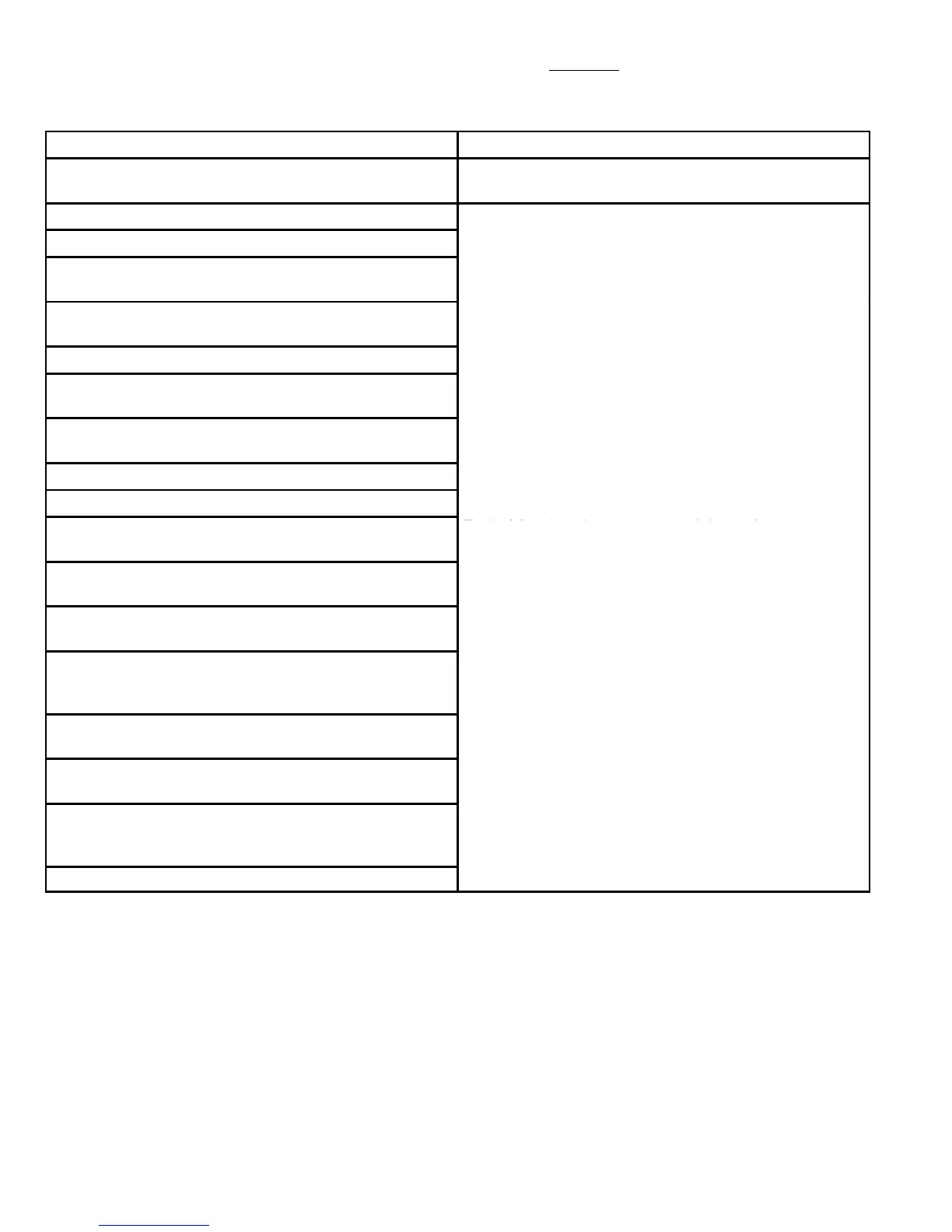

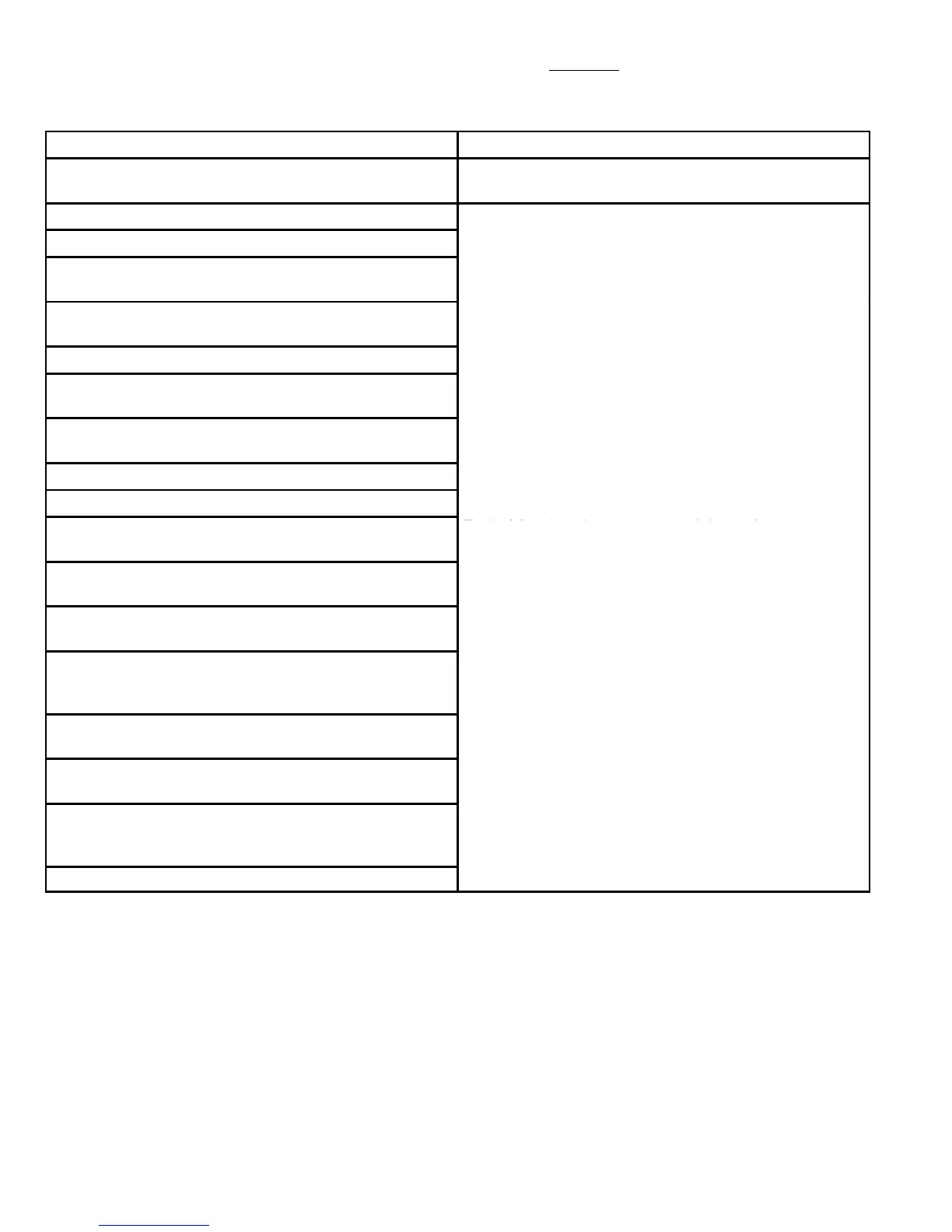

SCHEDULED MAINTENANCE THAT CAN BE PERFORMED BY DEALER

NOTE: Only perform maintenance which applies to your particular power package.

Task Interval

Seawater Pickup Pump - Disassemble and inspect

Whenever insufficient seawater flow is suspected.

(If operating temperature exceeds normal range.)

Crankcase Oil and Filter Change

Ignition system - Clean and Inspect condition.

Flame Arrestor and Crankcase Ventilation Hose -

Clean and Inspect.

Positive Crankcase Ventilation (PCV) Valve

(If Equipped) - Change

Stern Drive unit Oil - Change

Gimbal Ring Clamping Screws

Retorque to 50-55 ft. lb. (67-74 N·m)

Rear Engine Mounts

Check torque to 30-40 ft. lb. (47-54 N·m)

Gimbal Bearing - Lubricate

Cooling System - Clean and Inspect

Steering System - Lubricate and inspect for loose,

damage or missing parts.

End of first boating season and thereafter, every 100

hours of operation or once yearly, whichever occurs

Electrical System - Check for loose or damaged

wiring.

first.

Closed Cooling System Pressure Cap - Clean,

inspect and test.

Cooling System Hoses and Clamps - Inspect for

damage and deterioration. Check clamps for

tightness.

Continuity Circuit - Check components for loose

connections, broken or frayed wires.

Shift and Throttle Cable and Linkage - Lubricate and

inspect for loose, damaged or missing parts.

Engine Exhaust System - Inspect externally for

damage, deterioration and restrictions. Check for

tightness.

Ignition System - Check Timing and adjust as needed.

Loading...

Loading...