4-11

4-10. Teach weld section (Welding spec.)

Welding robots are provided with functions for operation frequently used in welding (welding ON/OFF operation) for easy

operation.

4-10-1. Wire/inching Gas check

Turn ON the

Wire/gas

check

icon lamp in the menu bar, to use the

Function keys for wire/inching gas check.

Function keys Functions

Wire feed forward

While holding down the key, wire feeds forward without outputting welding

non-load voltage. The wire will be fed at low speed for the first 3 seconds after the

key is pressed. Then the speed will be changed to high.

Wire feed backward

While holding down the key, wire feeds backward without outputting welding

non-load voltage. The wire will be fed at low speed for the first 3 seconds after the

key is pressed. Then the speed will be changed to high.

Gas check

While the green lamp is lit on, the gas valve is open.

Each time the key is pressed the gas ON/OFF state is switched.

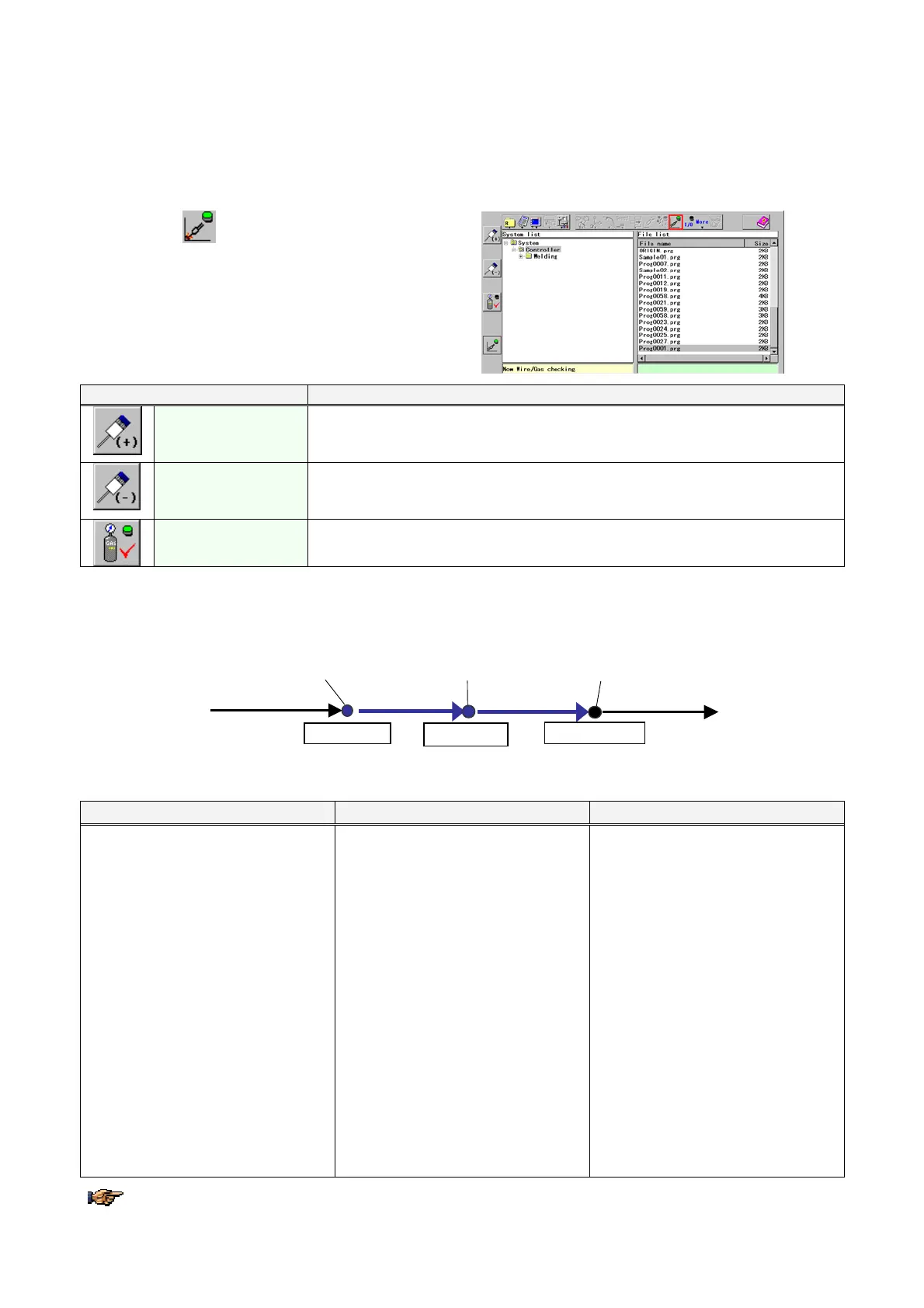

4-10-2. Teaching welding points and air-cut points

Store the welding start point and the intermediate point as “Weld” points, and the welding end point as “Air-cut” point.

Intermediate

point

Welding start point

Set “Weld”

Welding end point

Set “Air-cut”

Welding section Welding sectionAir-cut section Air-cut section

RC-SET

RC-ON

CRATER

RC-OFF

Set “Weld”

Teaching of a welding start point Teaching of intermediate point(s) Teaching of a welding end point

1. Move the robot to the point to

you want to start welding and

press the Enter key. Then the

dialog box to set teaching point

appears.

2. Change the attribute in the

dialog box to “Weld”.

3. Press the Enter key to save the

point as a welding start point.

1. Move the robot to a point within

the welding section and press

the Enter key. Then the dialog

box to set teaching point

appears.

2. Check the attribute in the dialog

box that “Weld” is specified.

3. Press the Enter key to save the

point as an intermediate point.

1. Move the robot to the point you

want to end welding and press

the Enter key. Then the dialog

box to set teaching point

appears.

2. Change the attribute in the

dialog box to “Air-cut”.

3. Press the Enter key to save the

point as a welding end point.

Note)

In a welding start point, commands to

start welding; ARC-SET (that

specifies welding current, voltage

and speed) and ARC-ON (that

specifies the program to start welding

operation) will be saved

automatically.

Note)

To change welding conditions at an

intermediate point, newly save

ARC-SET command (to change all

welding current, voltage and speed),

AMP (to change only welding current)

or VOLT (to change only welding

voltage).

Note)

In a welding end point, commands to

end welding; CRATER (that specifies

crater welding current, voltage and

time) and ARC-OFF (that specifies

the program to end welding

operation) will be saved

automatically.

Instead of the Enter key, you can click the OK button on the screen to save a teaching point.

Loading...

Loading...