10-3

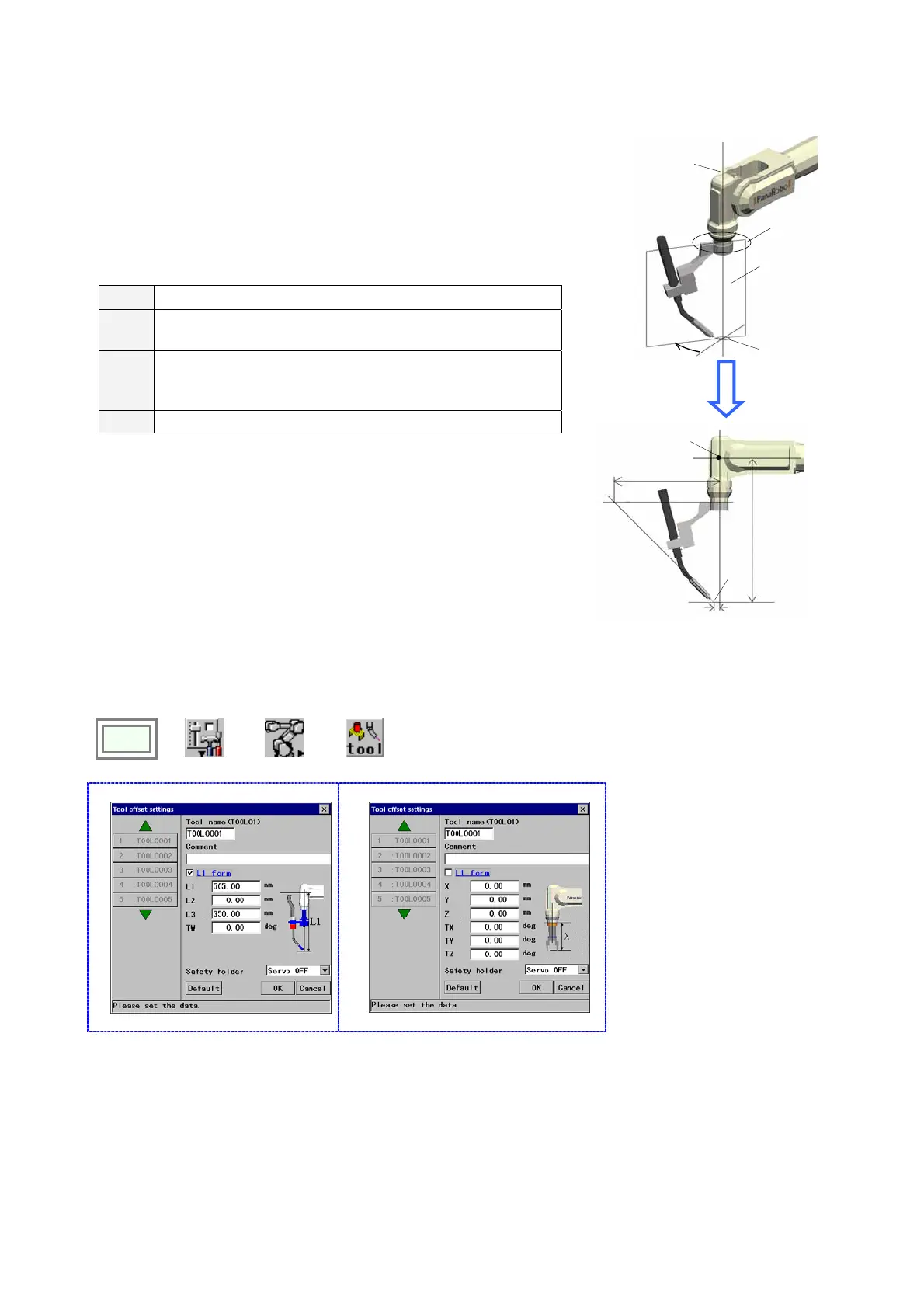

10-2-3. Definition of L1 type tool offset

• It uses 4 parameters, L1, L2, L3 and TW, to determine the tool

offset.

• When the BW axis is at –90 degrees, define the intersection

point of RW-axis and TW-axis as “point P” and the plane on

which the control point travels by moving only the TW-axis as

“plane Q”.

L1

Distance (in millimeters) between point P and plane Q.

L2

Distance (in millimeters) between the control point and the

TW rotation center.

L3

Distance (in millimeters) between the intersection point the

extension of the flange surface and the extension of the tool

direction intersects and the TW-axis rotation center.

TW Tool setting angle (in degree) measured from TW=0

* For details of each parameter, refer to manual of applied

equipment.

TW

Plane of L1,

L2 and L3

Plane Q

TW rotation

center

Flange

surface

+

L

2

L1

L3

Point P

Control

point

L2

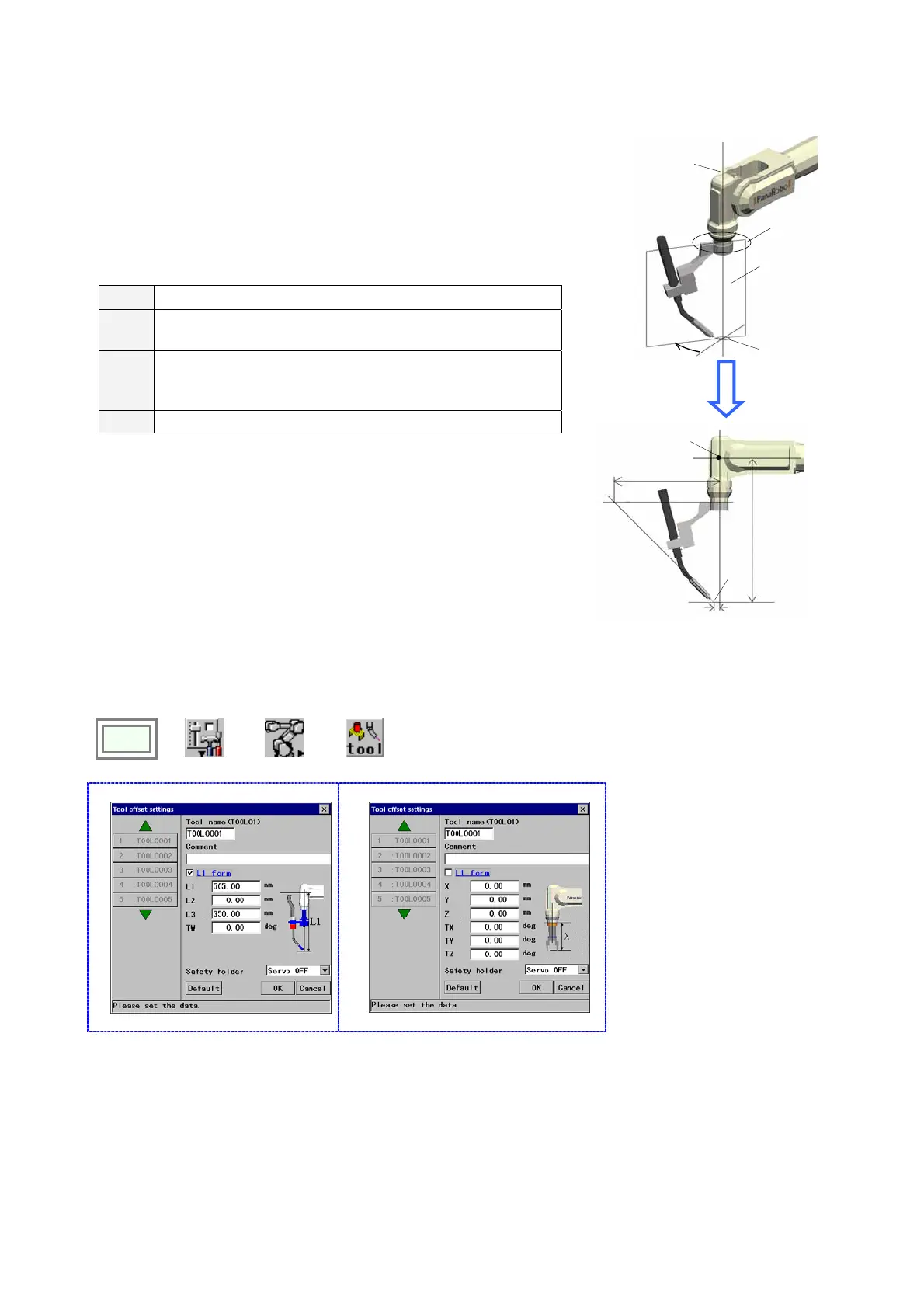

10-2-4. Setting procedure

Set the control point of the manipulator on which an interpolation movement of the robot is controlled to be operated.

Click

>>

Set

>>

Robot

>>

Tool

(Welding robots)

Î

(Handling robots)

Î

[Tool name] Type the tool name (the

identifier of each tool) you want to work

on. The Tool name can have up to 20

characters.

[Comment] Provides a space for you to

add comment about the tool.

Comments can have up to 20

characters.

[L1 form] Click this box to apply the L1

form to set parameters.

Clear this box to apply the XYZ form.

[Safety holder] Specifies whether the

robot should be in the [Hold] state or in

the [Servo OFF] state when the safety

holder activates.

[Default] Resets the settings in this

dialog box to the factory settings at

shipment.

Loading...

Loading...