10-10

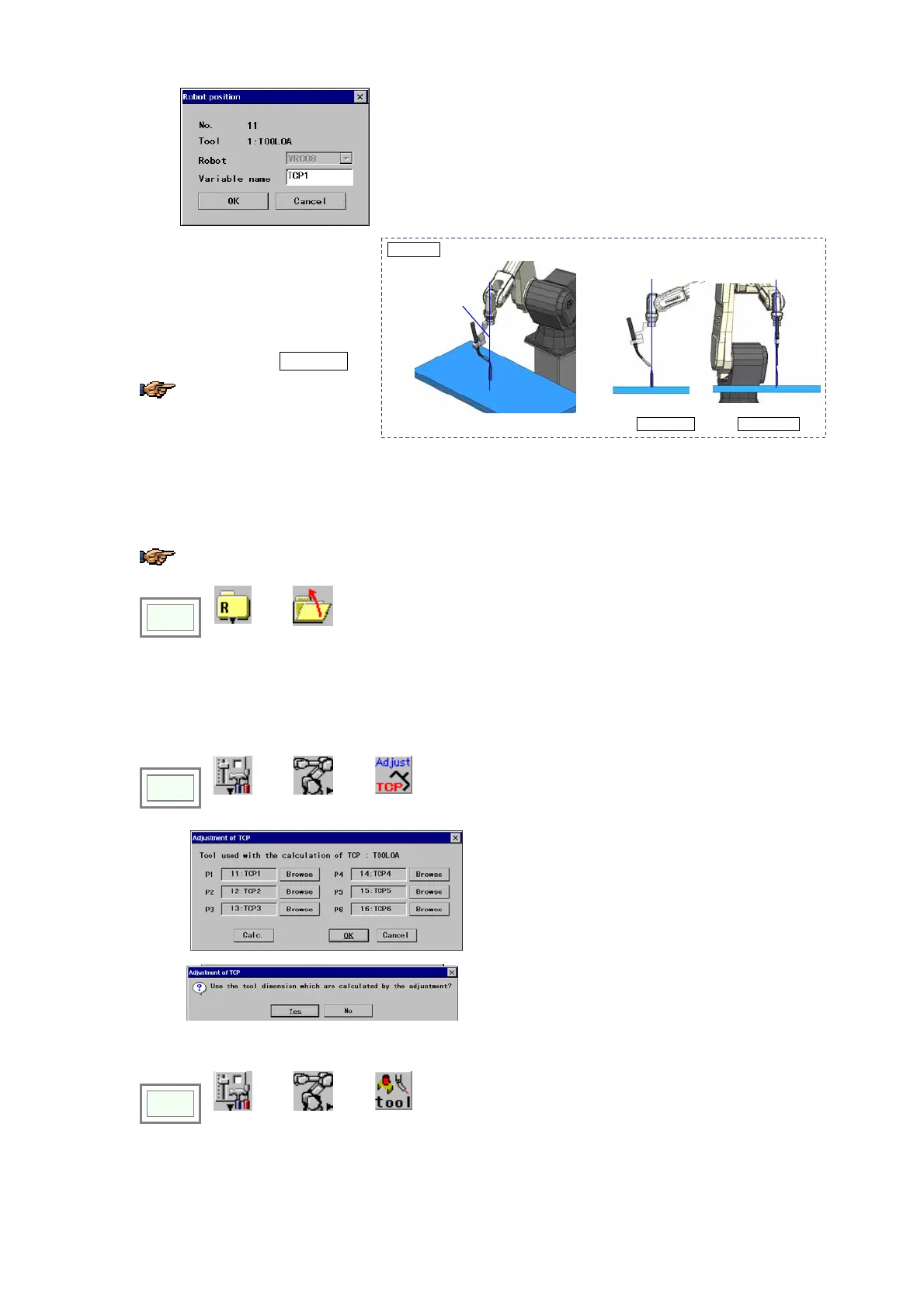

To identify the data as variable name, fill in the variable name box

and the click the OK button.

7.

<Position 2>

Then move the Y-axis of the tool

coordinate system to align the

directions of the adjustment jig and

of the TW axis rotation center as the

second position on the tool X-Z

plane. (See the figre Position 2.)

Only Y-axis of the tool

coordinate system is operable.

Position 2

Align the directions of the adjustment jig and of the TW axis rotation center.

TW axis

rotation center

Side view Front view

Move the cursor to the variable for the Position 2, and then press the ENTER key.

8. Rotate the Y-axis again to change the position for the third position on the tool X-Z plane. <Position 3>

9. As for Positions 4 to 6, teach position on the tool X-Y plane.

For Positions 5 and 6, only Z-axis of the tool coordinate system is operable.

10.

Click

>>

File

>>

Close

to close the list of the robot variables.

Then a dialog box to confirm updating the adjustment appears. Click the OK button.

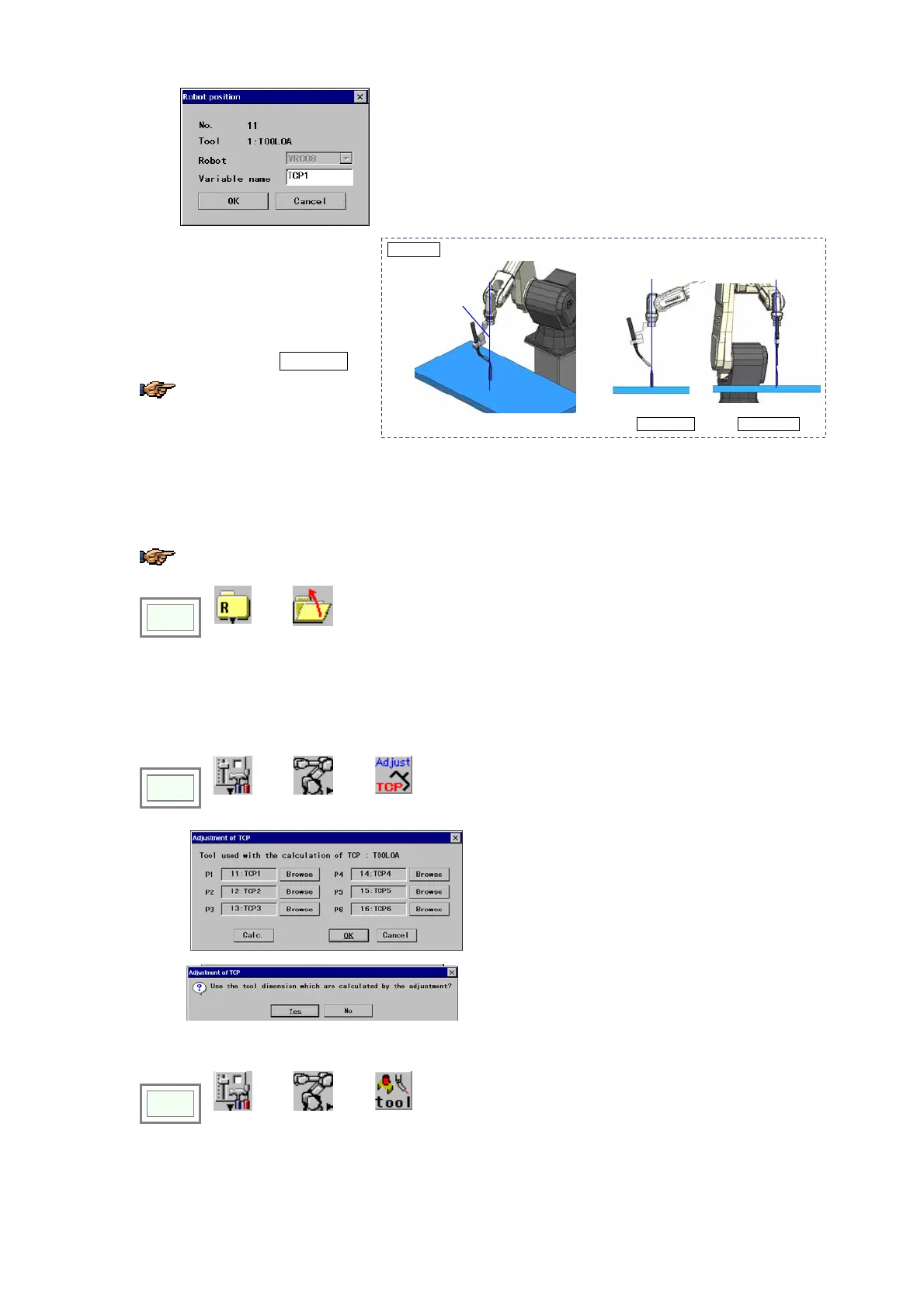

(2) TCP offset value calculation

1.

Click

>>

Set

>>

Robot

>>

TCP

adjust

Î

If all positions has stored properly, the preset

variable names are indicated in the P1 to P6 boxes.

Then click the Calc. button.

2.

Click the OK button, then the dialog box to confirm

the adjustment appears. Click the Yes button to

complete the adjustment.

3. Check the adjusted tool offset value.

Click

>>

Set

>>

Robot

>>

Tool

Loading...

Loading...