143

Pressing key causes moving to the control process with simultaneous

saving the determined average mass of a packaging in product record in the

database.

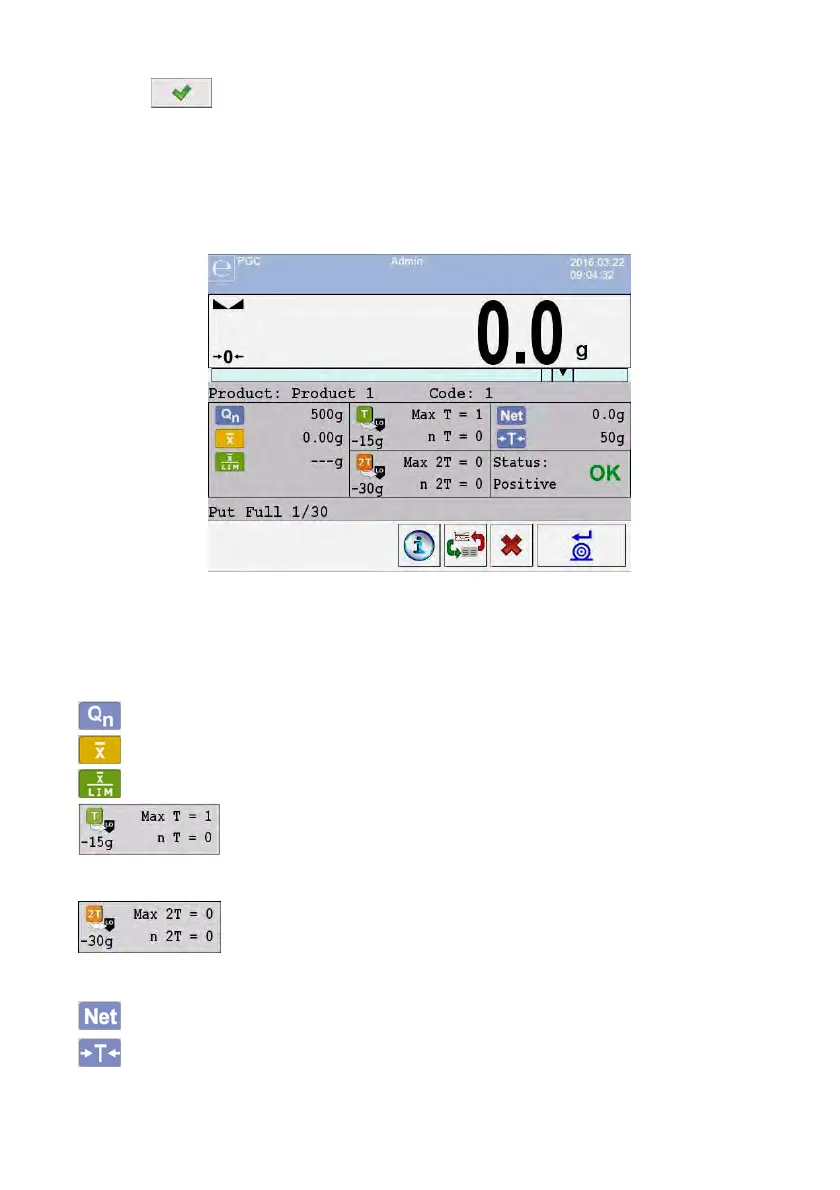

During the control process in progress the software carries out real-time

updating of measurement results and displays them in the corresponding fields

for informing an operator on control result:

Where:

Product

- Name of the controlled product

Code

- Code of the controlled product

- Nominal value of the controlled product

- Average mass of the controlled product

- Value of the disqualifying average

- Characteristics of negative errors T in a sample:

-15g – value of the negative error T,

Max T – permissible number of the negative errors T,

n T – actual number of the negative errors T

- Characteristics of negative errors 2T in a sample:

-30g - value of the negative error 2T,

Max 2T - permissible number of the negative errors 2T,

n 2T - actual number of the negative errors 2T

- Net mass of the controlled product

- Tare of the packaging

Loading...

Loading...