ENGINE

M6040, M7040, WSM

1-S62

Cylinder Head Flaw

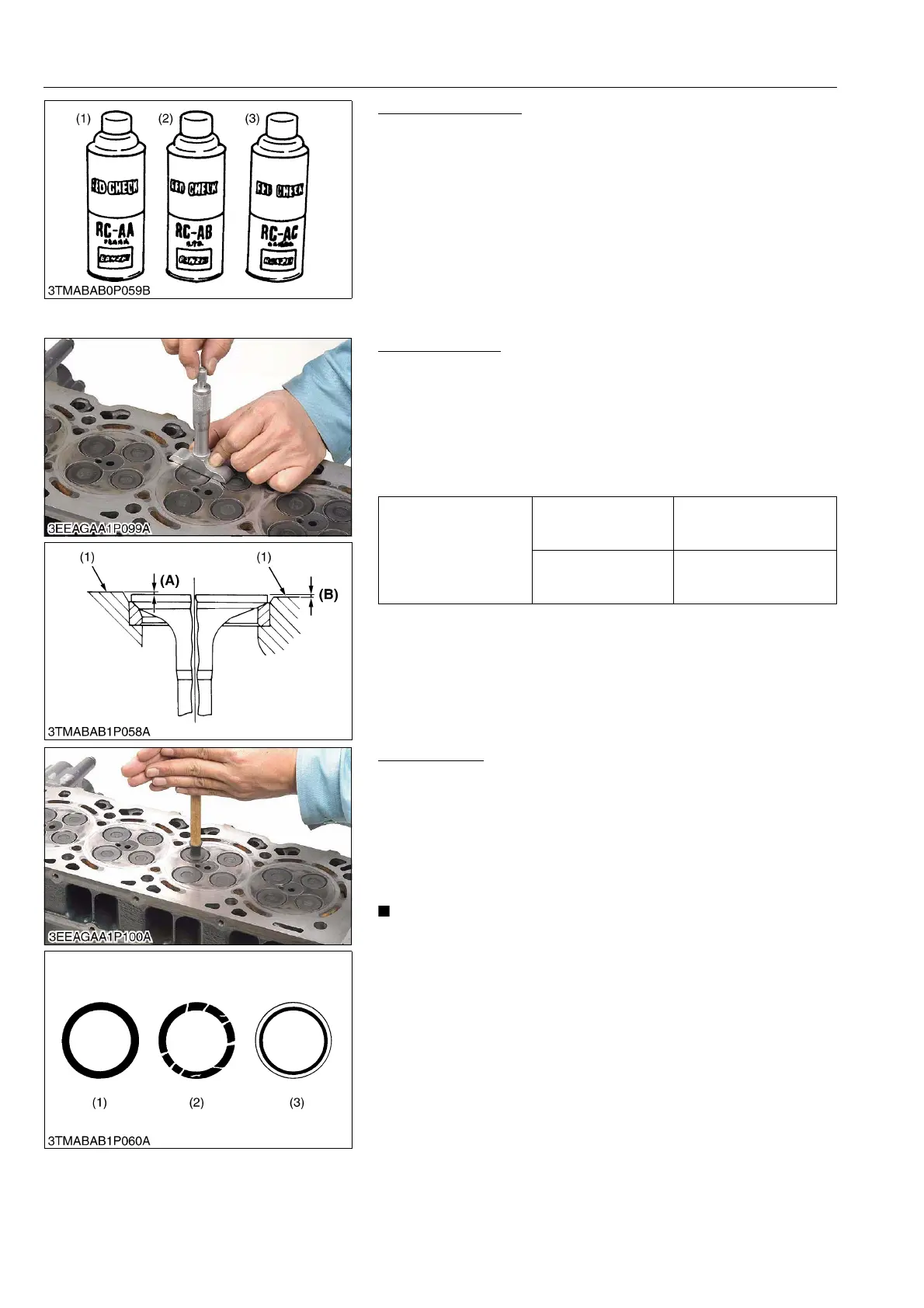

1. Prepare an air spray red check.

2. Clean the surface of the cylinder head with the detergent (2).

3. Spray the cylinder head surface with the red permeative liquid

(1). Leave it five to ten minutes after spraying.

4. Wash away the red permeative liquid on the cylinder head

surface with the detergent (2).

5. Spray the cylinder head surface with the white developer (3).

6. If flawed, it can be identified as red marks.

9Y1210143ENS0088US0

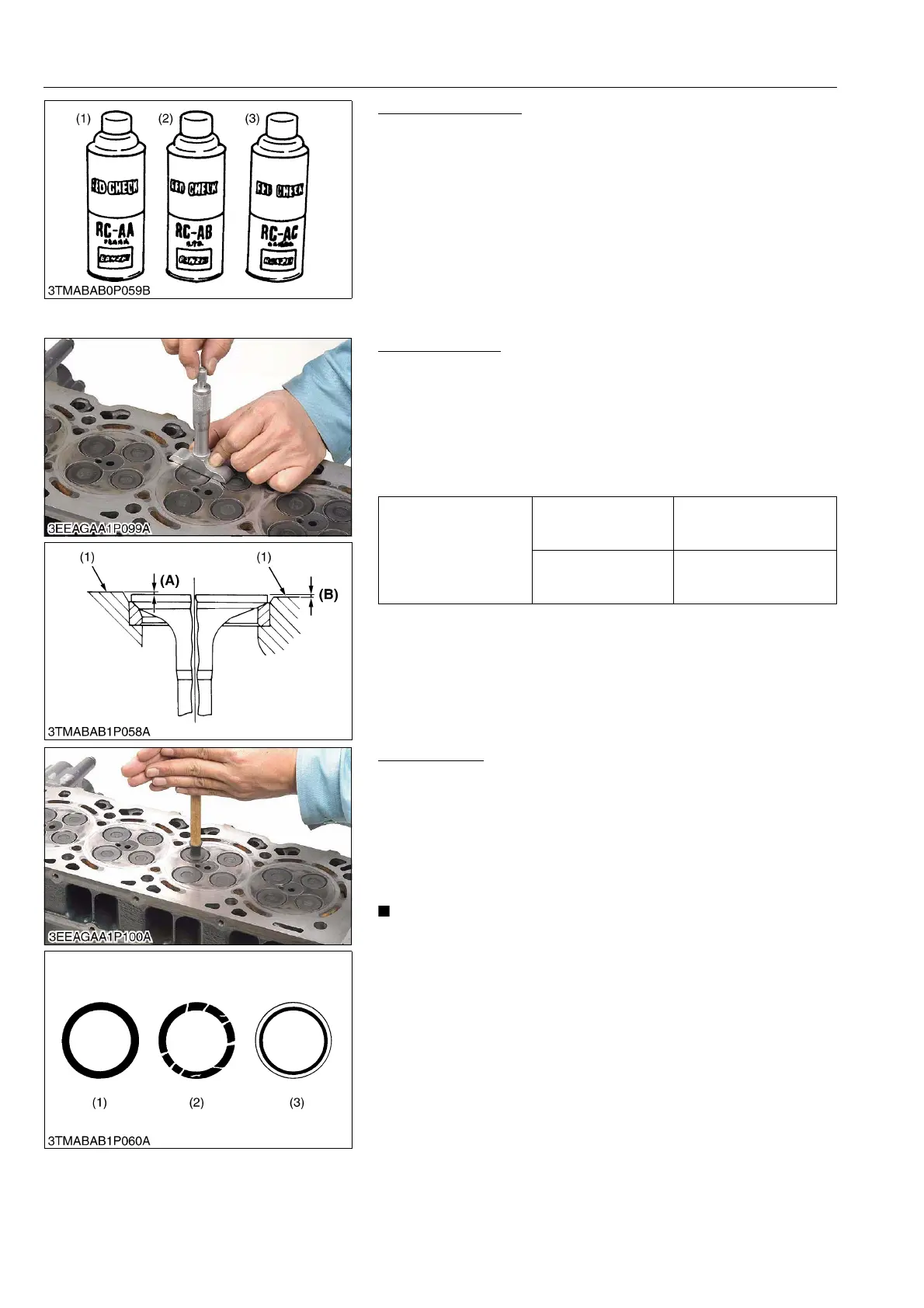

Valve Recessing

1. Clean the cylinder head, the valve face and seat.

2. Insert the valve into the valve guide.

3. Measure the valve recessing with a depth gauge.

4. If the measurement exceeds the allowable limit, replace the

valve.

If it still exceeds the allowable limit after replacing the valve,

replace the cylinder head.

9Y1210143ENS0089US0

Valve Lapping

1. Apply compound evenly to the valve lapping surface.

2. Insert the valve into the valve guide. Lap the valve onto its seat

with a valve flapper or screwdriver.

3. After lapping the valve, wash the compound away and apply oil,

then repeat valve lapping with oil.

4. Apply prussian blue to the contact surface to check the seated

rate. If it is less than 70 %, repeat valve lapping again.

• When valve lapping is performed, be sure to check the

valve recessing and adjust the valve clearance after

assembling the valve.

9Y1210143ENS0090US0

(1) Red Permeative Liquid

(2) Detergent

(3) White Developer

Valve recessing

(Intake and exhaust)

Factory specification

(recessing)

0.65 to 0.85 mm

0.0256 to 0.0335 in.

Allowable limit

(recessing)

1.2 mm

0.0472 in.

(1) Cylinder Head Surface (A) Recessing

(B) Protrusion

(1) Correct

(2) Incorrect

(3) Incorrect

Loading...

Loading...