FRONT AXLE

M6040, M7040, WSM

6-S14

[4] SERVICING

Backlash and Tooth Contact between Bevel Pinion Shaft and

Bevel Gear

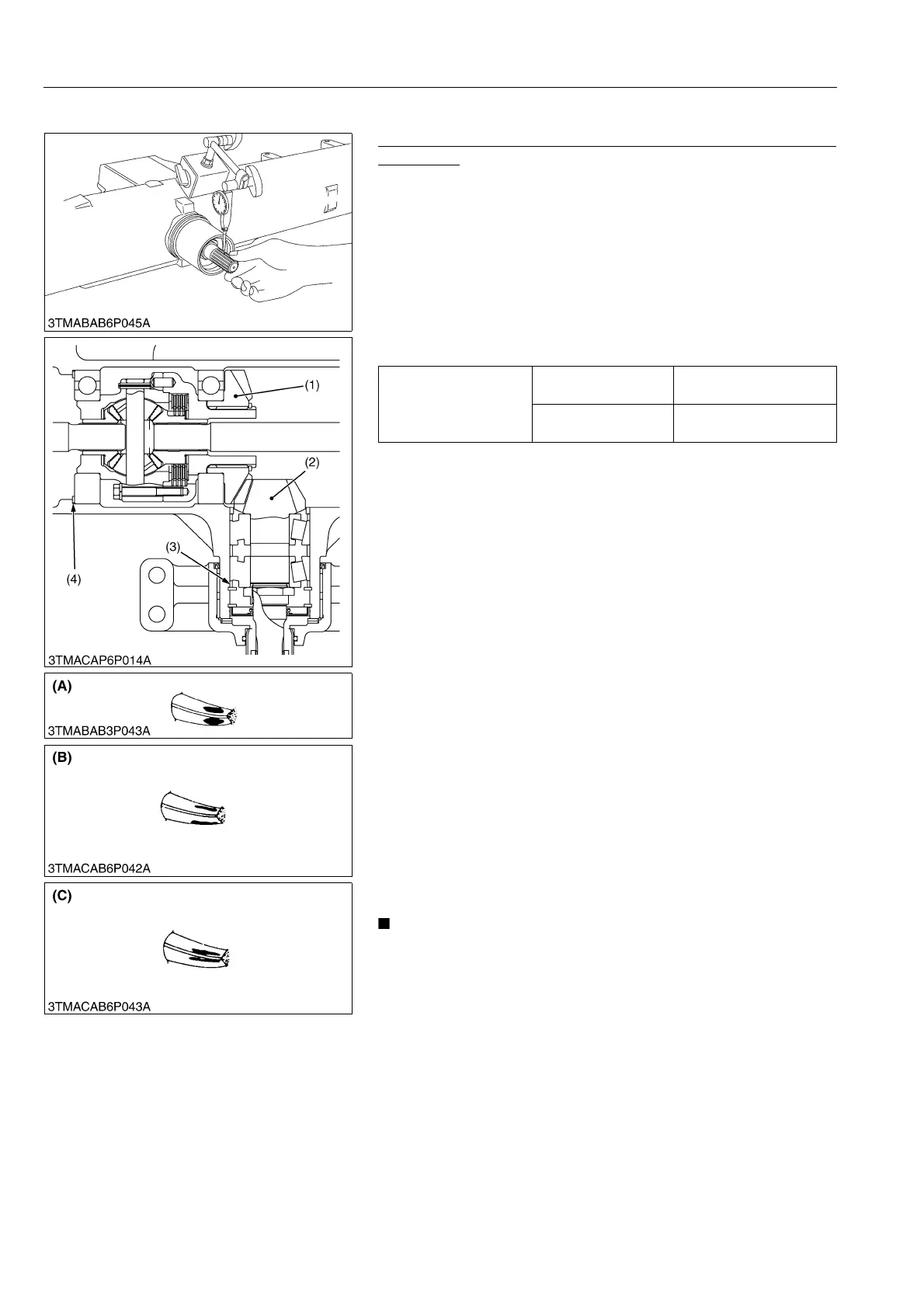

1. Set a dial indicator (lever type) with its finger on the tooth

surface.

2. Measure the backlash by fixing the bevel pinion shaft (2) and

moving the bevel gear (1) by hand.

3. Calculate the backlash from the ratio of the shaft diameter to the

gear diameter. (Backlash = play × 2.0)

4. If the backlash exceeds the allowable limit, adjust with the shim

(4).

5. Adjust the backlash properly by repeating the above

procedures.

6. Apply red lead lightly over several teeth at three positions

equally spaced on the bevel gear (1).

7. Turn the bevel pinion shaft (2), against the periphery of the

bevel gear.

8. Check the tooth contact. If not proper, adjust according to the

instructions shown in the figure.

(Reference)

• Thickness of adjusting collar (3):

5.8 mm (0.229 in.) [Code No.: 3C011-43010]

5.9 mm (0.233 in.) [Code No.: 3C011-43020]

6.0 mm (0.237 in.) [Code No.: 3C011-43030]

6.1 mm (0.241 in.) [Code No.: 3C011-43040]

6.2 mm (0.245 in.) [Code No.: 3C011-43050]

6.4 mm (0.252 in.) [Code No.: 3C011-43070]

• Thickness of adjusting shims (4):

0.7 mm (0.028 in.) [Code No.: 3A151-32180]

0.8 mm (0.032 in.) [Code No.: 3A151-32130]

1.0 mm (0.039 in.) [Code No.: 3A151-32140]

1.2 mm (0.047 in.) [Code No.: 3A151-32150]

1.4 mm (0.551 in.) [Code No.: 3A151-32160]

2.3 mm (0.091 in.) [Code No.: 3A151-32170]

• Standard size of collar (3): 0.5 mm (0.020 in.)

Standard size of shim (4): 1.2 mm (0.047 in.)

• Backlash changes per 0.1 mm (0.004 in.) shim:

Approx. 0.05 mm (0.002 in.)

• Adjust the tooth contact with collar (3) and shim (4) so that

the spiral bevel pinion shaft may not contact with the

differential case.

9Y1210143FAS0023US0

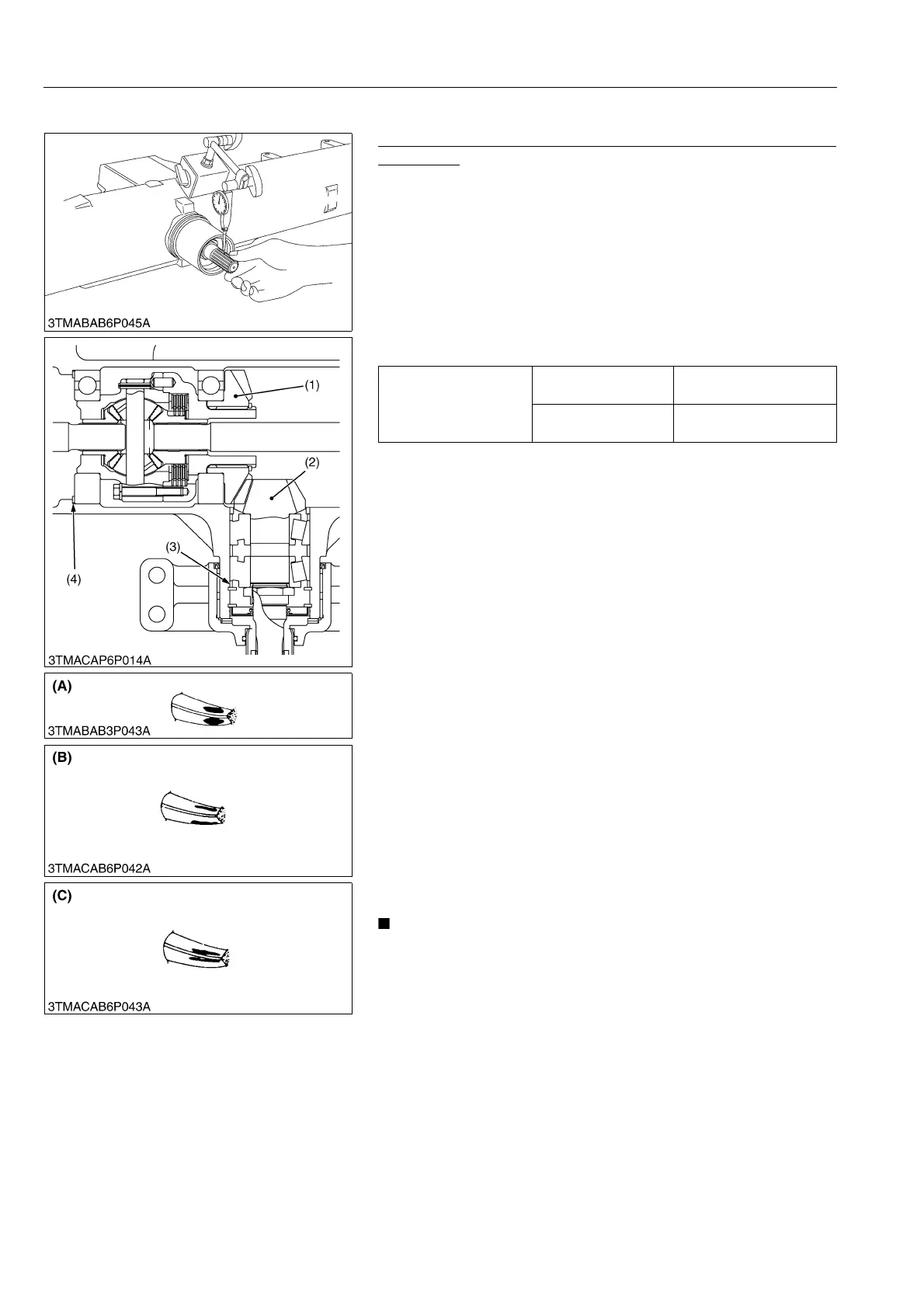

Backlash between bevel

gear and bevel pinion

shaft

Factory specification

0.20 to 0.30 mm

0.0079 to 0.0118 in.

Allowable limit

0.4 mm

0.016 in.

(1) Bevel Gear

(2) Bevel Pinion Shaft

(3) Collar

(4) Shim

(A) Proper Contact:

More than 35 % red lead contact

area on the gear tooth surface.

The center of tooth contact at 1/3

of the entire width from the small

end.

(B) Deep Contact:

Decrease the shims.

(C) Shallow Contact:

Increase the shims.

Loading...

Loading...