Chapter 9 Inverter Functions

9-5-13

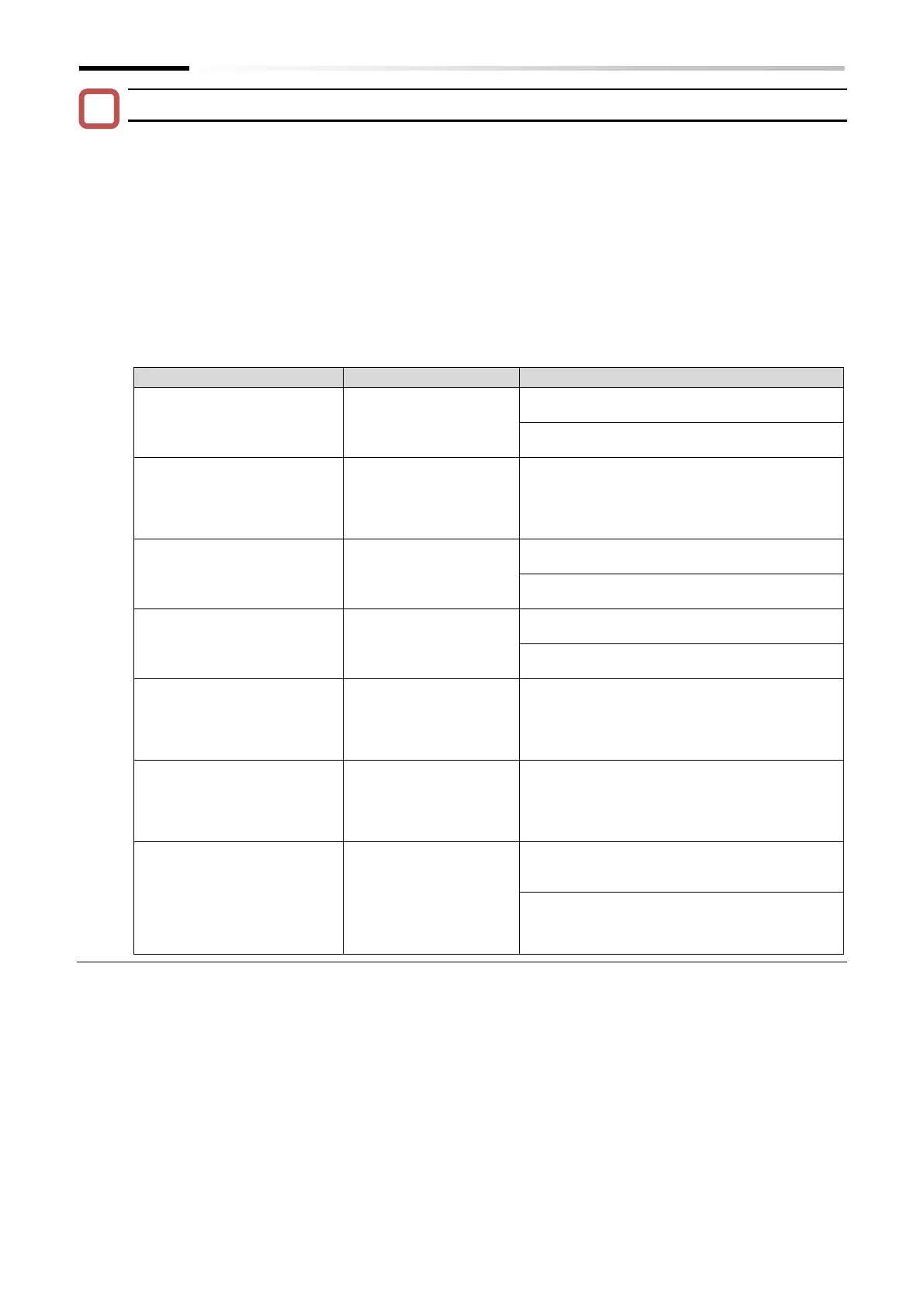

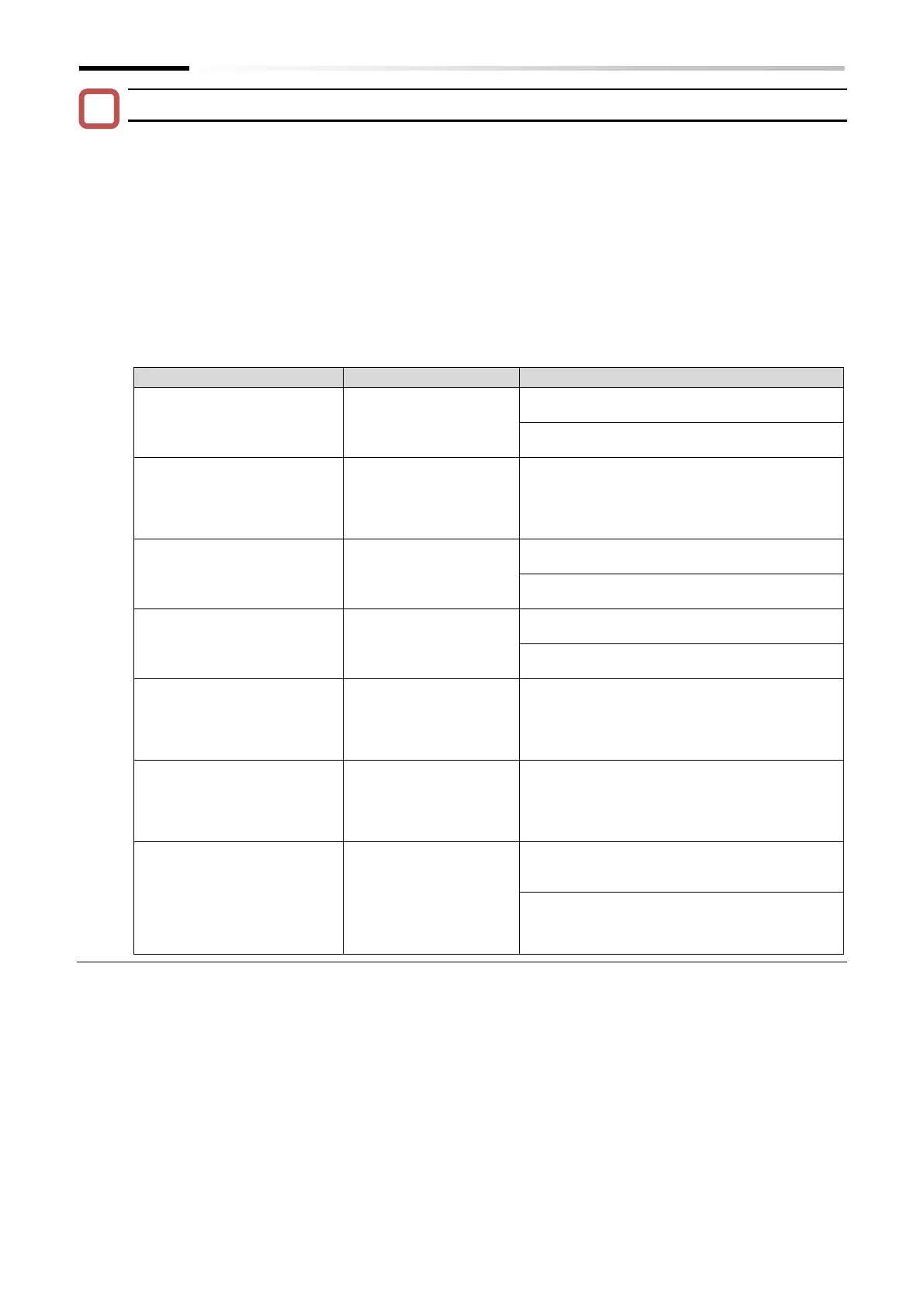

Adjustments when using sensorless vector control

If the desired characteristics cannot be obtained, first execute auto-tuning to set the motor

constant. Then, apply adjustments referring to the table below.

Before adjusting the "Async. Motor speed response [H005]

*1

", set the "Async. Motor constant J

[H024]/[H034]

*1

" to the sum of the moment of inertia of the load applied to the motor shaft and

the moment of inertia of the motor.

Overcurrent and other issues may occur if motor rotation is obstructed due to motor locking

from braking or interference from foreign objects. If this cannot be resolved with adjustments,

try checking around the motor's periphery.

If the "Output frequency monitor [d001]" changes significantly under load, a function that makes

automatic changes to the frequency, such as the overload limit function, non-stop operation

during instantaneous power failure, or the overvoltage suppressor, may have been triggered

under certain function settings. For details, refer to "Chapter 15 Tips/FAQ/Troubleshooting".

Example of countermeasures

The speed response of

the control system is

too high.

Decrease the "Async. Motor speed response

[H005]

*1

" in 5% increments.

Decrease the "Async. Motor constant J [H024]/

[H034]

*1

" in 5% increments.

Rotation momentarily occurs

in the reverse direction to

the specified direction of

rotation at startup, or during

low-speed operation.

The result of the motor

control causes a reverse

rotation command to be

momentarily issued.

Enable "Direction reversal protection selection

[b046]".

Rotation is unstable and

uneven when operating at

low speeds.

The speed response of

the control system is

too low.

Increase the "Async. Motor speed response

[H005]

*1

" in 5% increments.

Increase the "Async. Motor constant J [H024]

/[H034]

*1

" in 5% increments.

Hunting occurs in the motor.

The speed response of

the control system is

too high.

Decrease the "Async. Motor speed response

[H005]

*1

" in 5% increments.

Decrease the "Async. Motor constant J [H024]

/[H034]

*1

" in 5% increments.

The rotation frequency

decreases when a load

(power running) is applied to

the motor in the stop

direction.

The motor constant R2

has been set too low.

Increase the "Async. Motor constant R2 [H021]

/[H031]

*1

" in 5% increments up to 1.2 times

the set value.

The rotation frequency

increases when a load

(power running) is applied to

the motor in the stop

direction.

The motor constant R2

has been set too high.

Decrease the "Async. Motor constant R2

[H021]/ [H031]

*1

" in 5% increments down to 0.8

times the set value.

The rotation frequency

increases when a load

(regenerative running) is

applied to the motor in the

direction of rotation during

low-speed operation (at

several Hz).

Regenerative torque is

insufficient for low-

speed operation.

Increase the "Async. Motor constant R1 [H020]

/[H030]

*1

" in 5% increments up to 1.2 times

the set value.

Increase the "Async. Motor constant I0 [H023]

/[H033]

*1

" in 5% increments up to 1.2 times

the set value.

*1. "2nd-motor control [SET]" target parameter. The second control parameter is also subject to setting.

Loading...

Loading...