Chapter 9 Inverter Functions

9-6-5

9.6.3 Driving by Torque Reference

How to control the motor to apply a constant torque?

How to control the stopping point?

How to apply a constant winding torque for a winding machine, or a similar device?

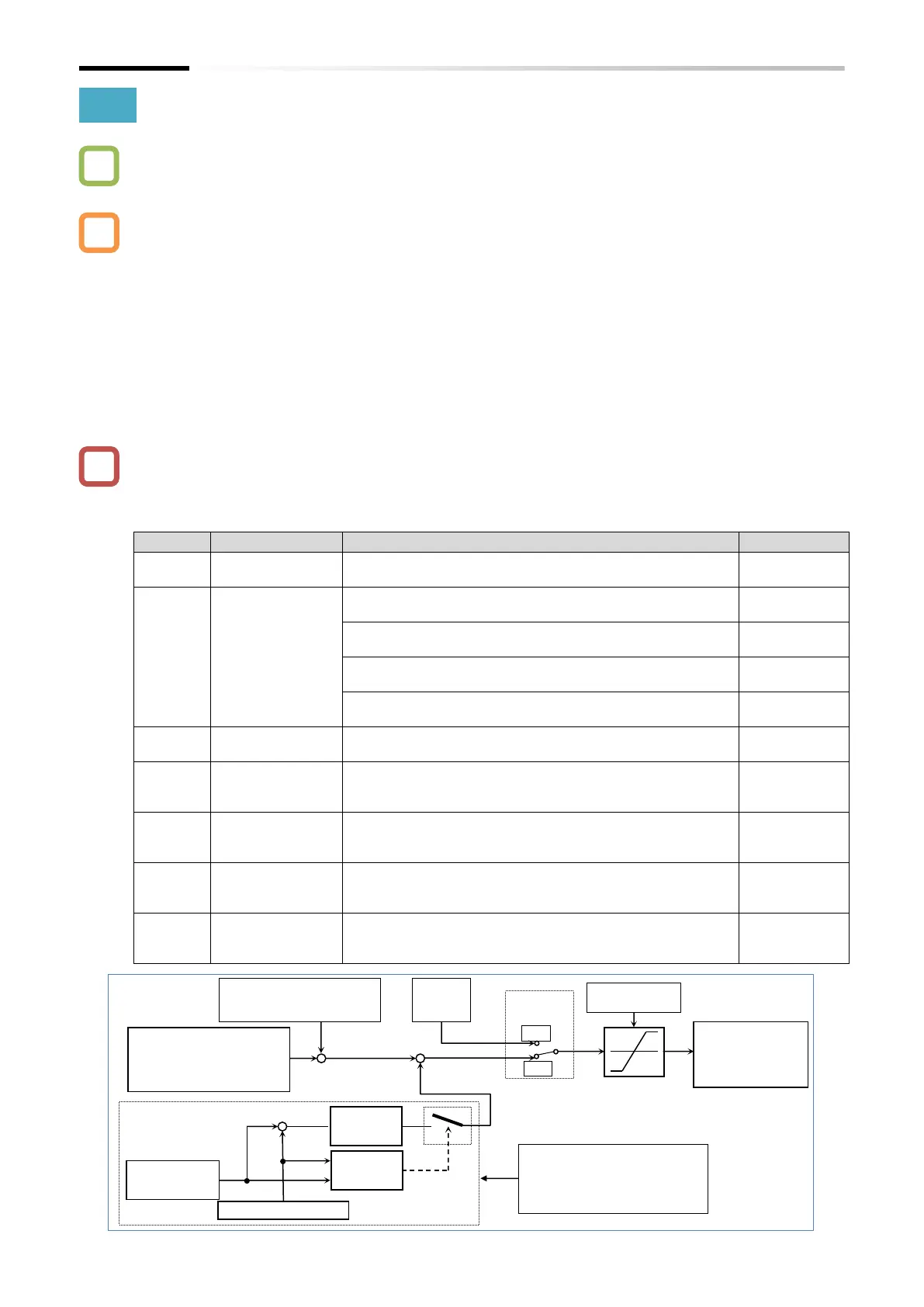

For motor operation using torque control, assign "Permission of torque control [ATR] (52)" to the

input terminal. Turn the [ATR] terminal ON to allow torque command input.

Select the torque command value input source in "Torque reference input source selection

[P033]".

If [P033] is set to "Parameter setting (03)", set the torque command value with the "Torque

reference [P034]". A torque command range of 0 to 200% is applied by an analog voltage 0 to

10 VDC input if [P033] is "[Ai1] terminal (00)", and an analog current 4 to 20 mA input if [P033]

is "[Ai2] terminal (01)".

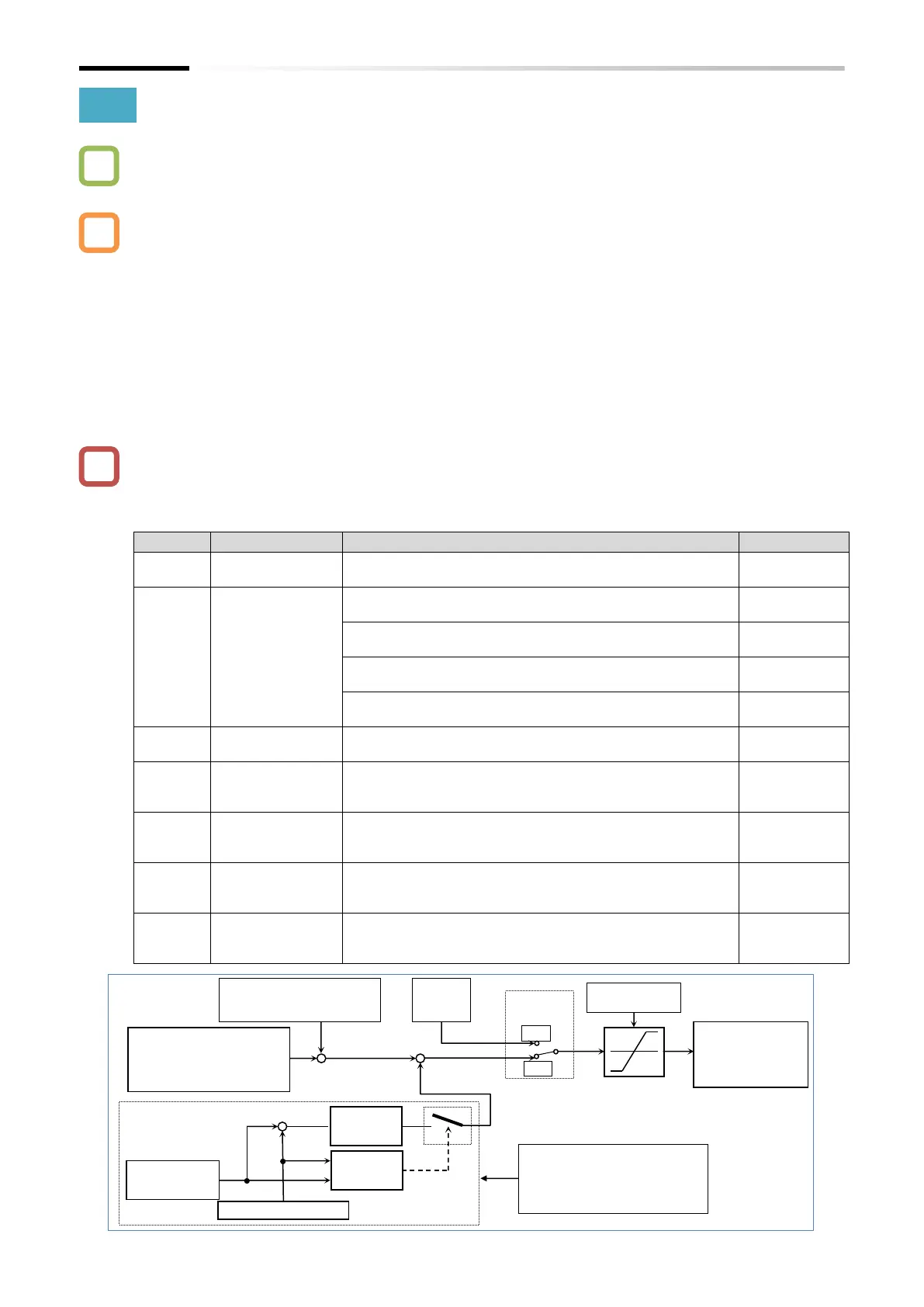

Switching between normal frequency control (speed control) and torque control may cause

shocks to the motor during operation due to differences in control. To reduce shock when

switching, adjust the "Switching time of speed control to torque control [P041]". Lengthen this

setting to alleviate shocks.

As speed is determined in balance with the load when using torque control, the output speed

increases if the actual output torque is lower in relation to the torque command. As such, set

speed limits using "Speed limit at torque control (at Forward rotation) [P039]" and "Speed limit

at torque control (at Reverse rotation) [P040]" to prevent runaway.

Loading...

Loading...