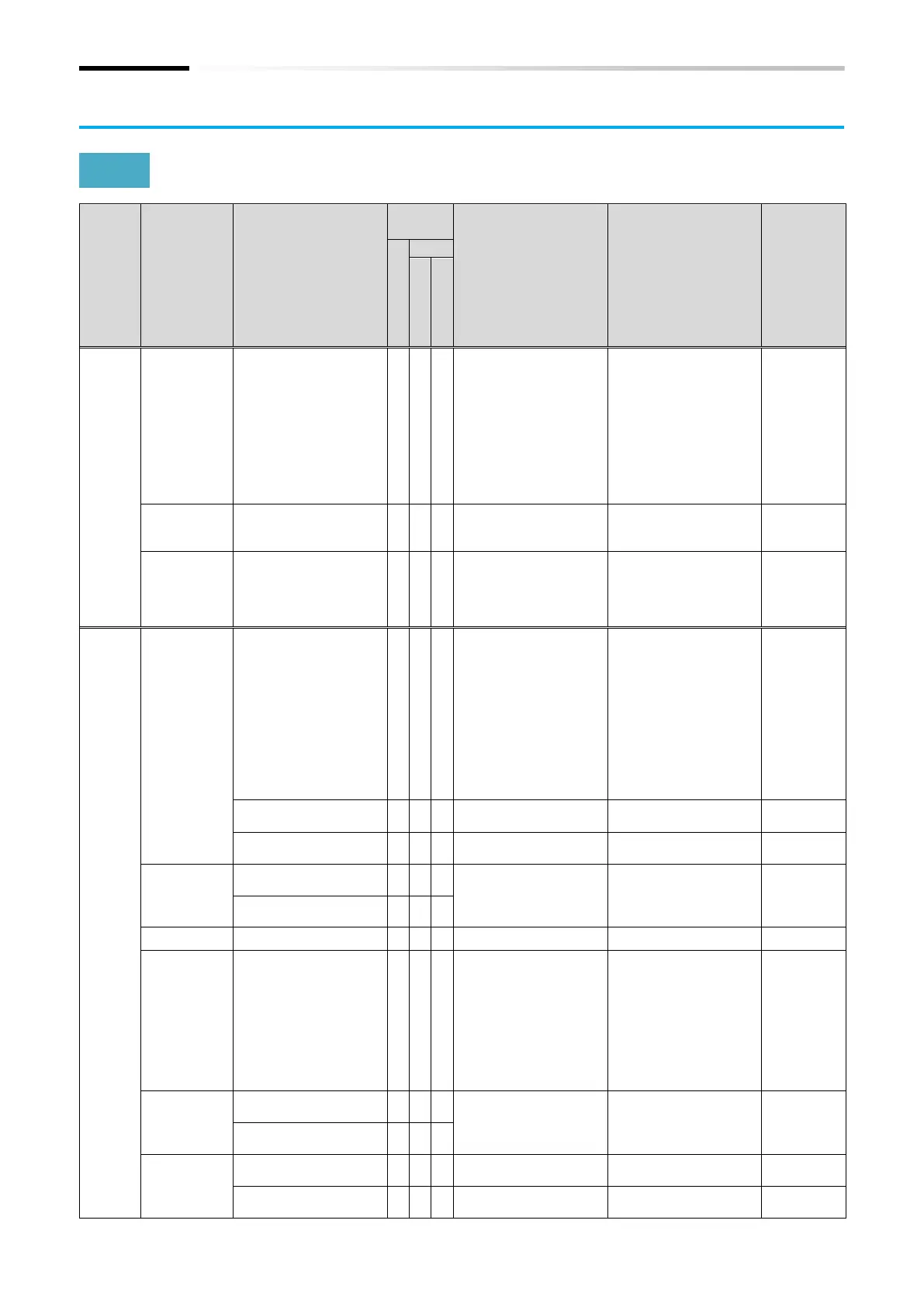

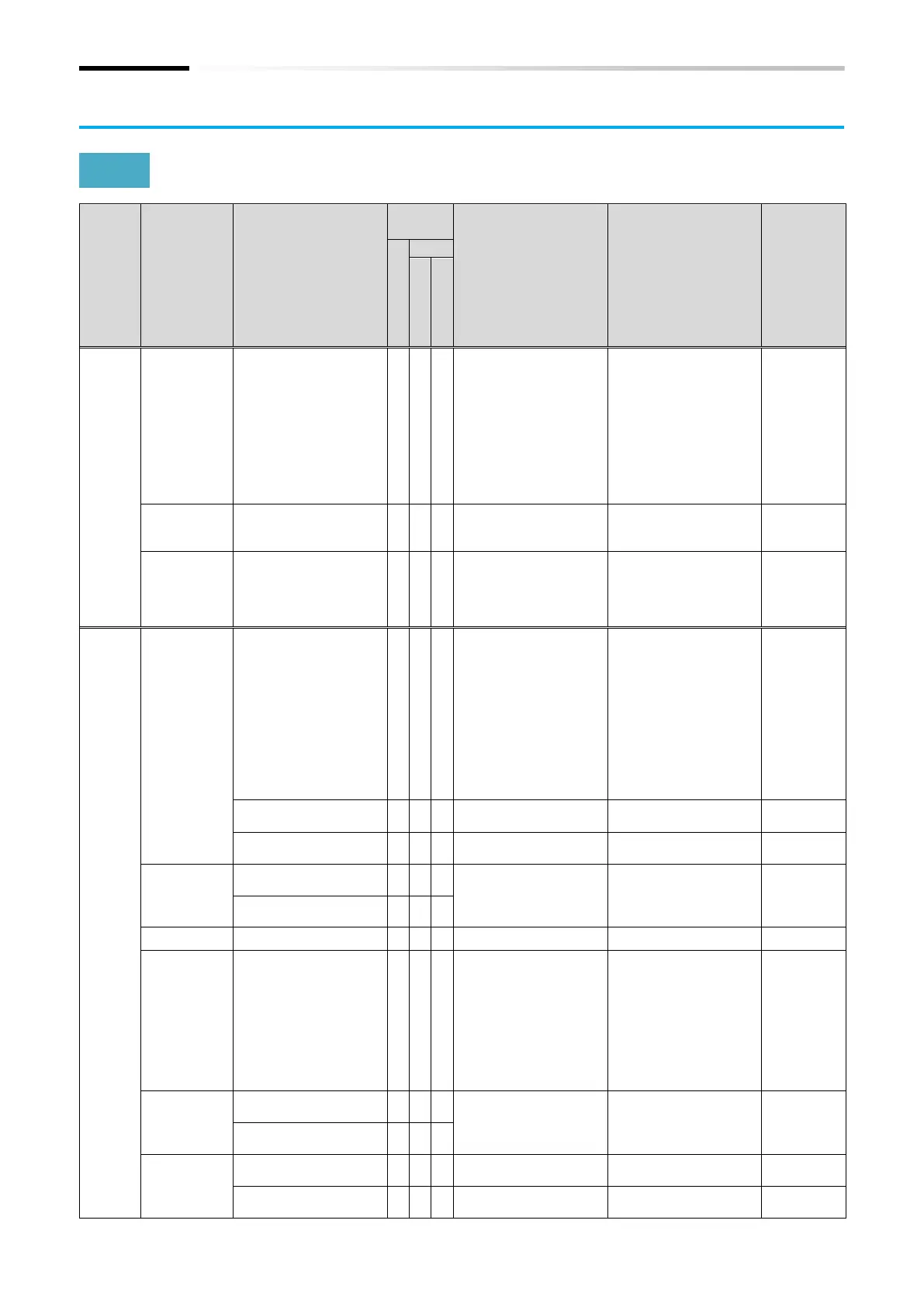

Chapter 16 Maintenance and Inspection

16-2-1

16.2 Daily Inspection and Periodic Inspection

16.2.1 Inverter Inspection List

Check the ambient

temperature, level of

humidity, dust, … etc..

Refer to "Chapter 4

Installation".

The ambient temperature

and level of humidity are

within the operating

range.

There are no freeze,

condensation, dust,

corrosive gas, explosive

gas, flammable gas,

grinding fluid mist,

hydrogen sulfide and salt.

Thermometer,

Hygrometer,

Data logger

Check that there are no

abnormal vibrations or

noises.

Check visually and

auditorily.

Check that the main

circuit voltage is normal.

Measure the line-to-line

voltage of the inverter

main circuit terminals

[R/L1], [S/L2], and [T/L3].

Within the allowable AC

voltage fluctuation.

Multimeter,

Digital

multimeter

Check the resistance

between the main circuit

and the ground terminals.

(between main circuit and

ground terminals)

Remove all wires from the

main circuit terminal block

and control circuit terminal

block of the inverter. Then,

shortcircuit the terminals

[R/L1], [S/L2], [T/L3],

[U/T1], [V/T2], [W/T3],

[P/+], [PD/+1], [N/-] and

[RB], and measure between

this shortcircuited part and

the ground terminal.

Resistance no less than 5

MΩ.

500 VDC

class

ohmmeter

(megger®)

Check looseness in

tightening parts.

Check for overheating

traces.

Check for straining in

conductors.

Check for cable coating

damage.

Inverter and

converter

circuits

(including

resistors)

Check the resistance

between all the terminals.

Remove all wires from the

main circuit terminal

block of the inverter.

Then measure between

[R/L1]/[S/L2]/[T/L3] -

[P/+]/[N/-], and between

[U/T1]/[V/T2]/[W/T3] -

[P/+]/[N/-] in the 1 Ω

range.

Refer to "16.2.4 Checking

the Inverter and

Converter Section".

Reference for

replacement of the

inverter ank converter

Start/Stop: 10

6

cycles

*3

Check for capacitor fluid

leakage.

No abnormality.

Approximate replacement

period: 10 years

*1*3*4

Check that the relief valve

does not swell or protude.

No chatter sound while

operating.

Check contacts for

damage.

Loading...

Loading...