215575 86 Revision B

Stripper Plate Clearance

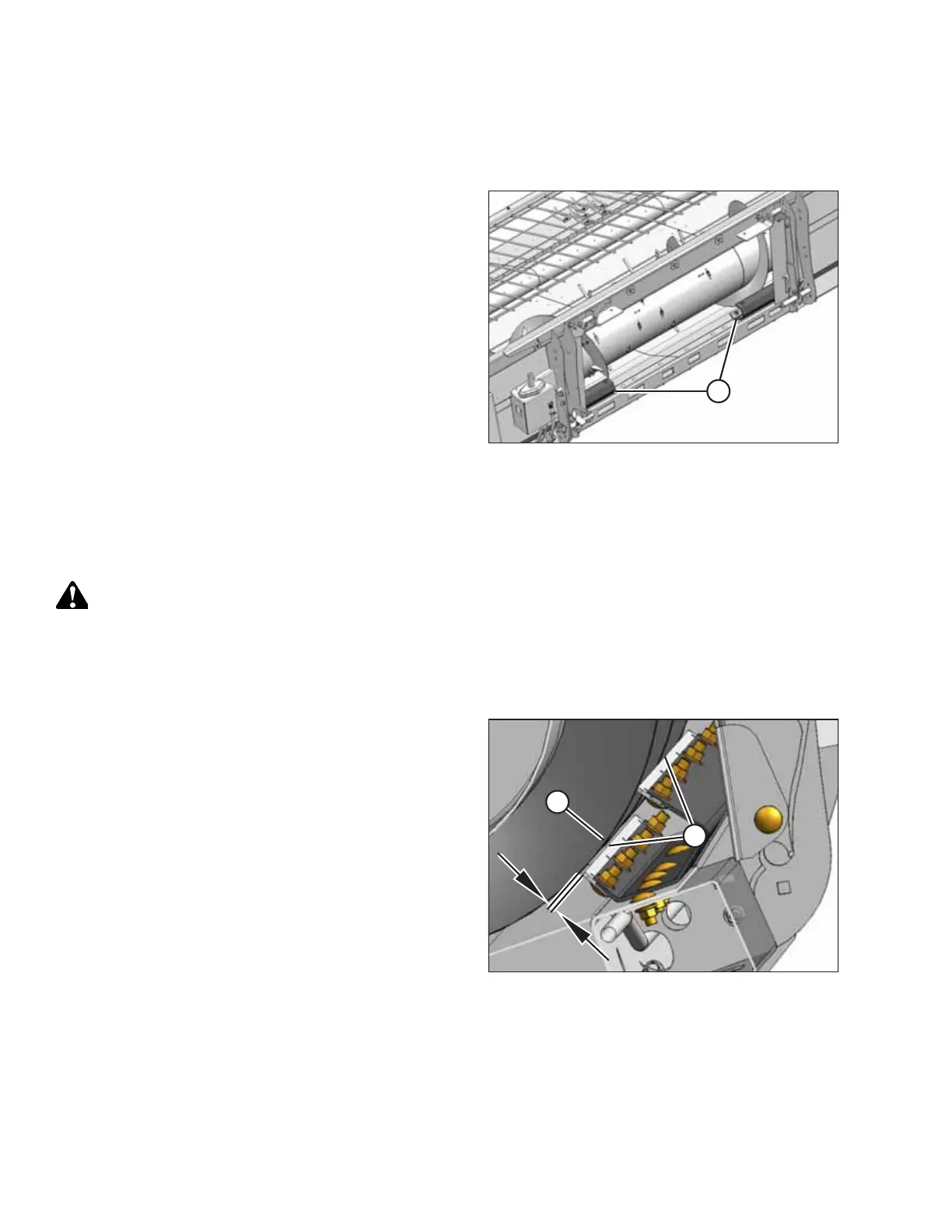

The pick-up header is equipped with a pair of stripper plates located on either side of the center opening. The stripper

plates are designed to minimize crop carryover behind the auger, but they require proper adjustment.

$

Figure 3.135: Stripper Plates

Stripper plates (A) can be found on either side of the header’s

center opening. The clearance between the stripper plates and

the auger flighting is factory-set to 3–8 mm (1/8–5/16 in.).

NOTE:

• If the clearance between the auger flighting and the stripper

plates is too large, crop has a tendency to wrap around the

auger, disrupting flow of crop into the combine.

• If the clearance is too small, the auger flighting may contact

the stripper plates, resulting in excessive wear to the flighting

and the stripper plates.

Checking Stripper Plate Clearance

Check the clearance between the stripper plates and the auger flighting whenever the auger position is changed. Adjust

the clearance if necessary.

WARNING

To avoid bodily injury or death from unexpected startup of machine, always stop the engine and remove the key from

the ignition before leaving the operator’s seat for any reason.

1. Lower the header to the ground.

2. Shut down the combine and remove the key from the ignition.

$

%

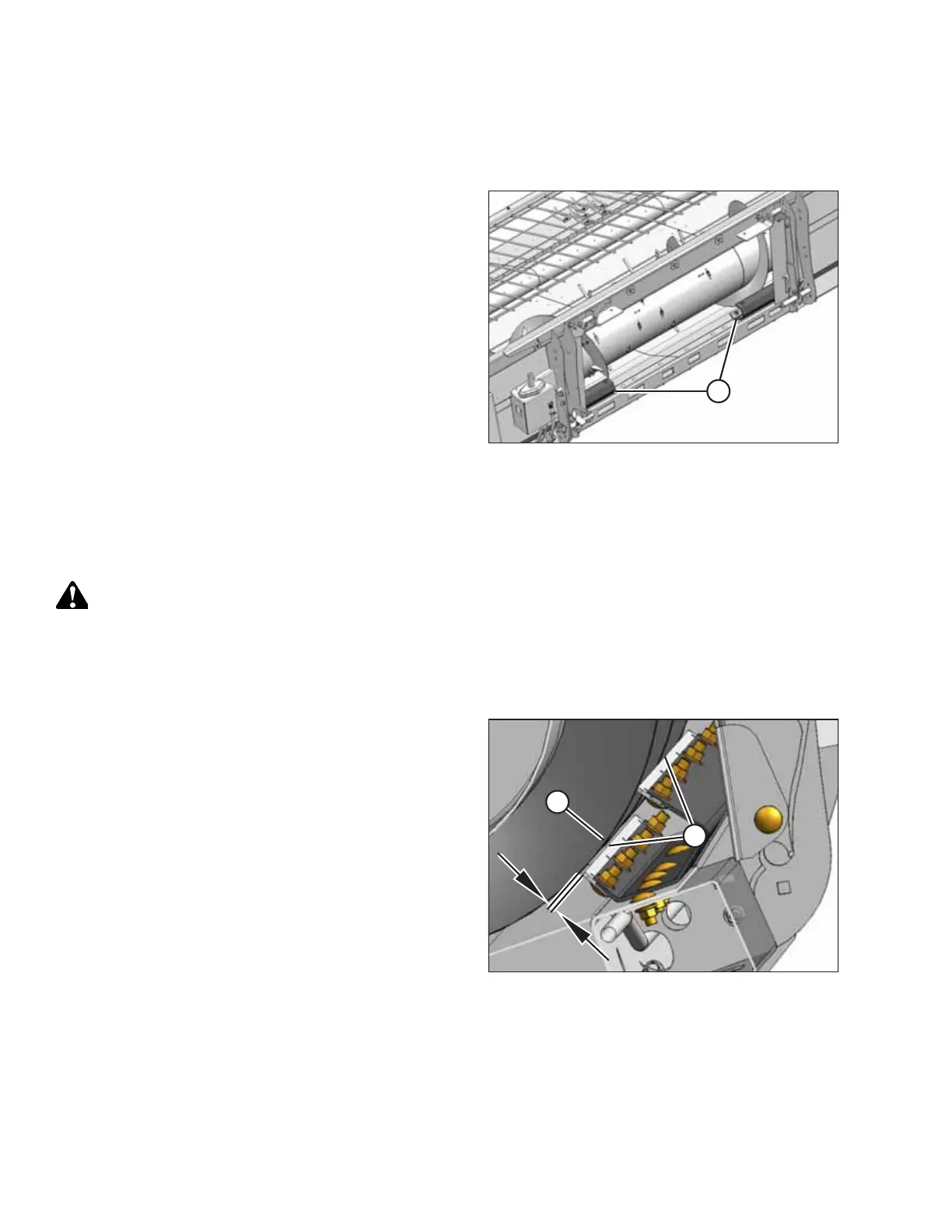

Figure 3.136: Stripper Plate Clearance

3. Rotate the auger manually to check for interference and to

check the clearance between auger flighting (A) and

stripper plates (B).

NOTE:

Access the auger/stripper plate area from the top of

the header.

4. Start the combine’s engine.

5. Run the header slowly, and listen for contact between

auger flighting (A) and stripper plates (B). Gradually

increase the speed of the header until it is operating at full

speed.

If there is any contact between the auger flighting and the

stripper plates, adjust the stripper plate clearance. For

instructions, refer to Adjusting Stripper Plate Clearance,

page 87.

OPERATION

Loading...

Loading...