215575 30 Revision B

$

%

&

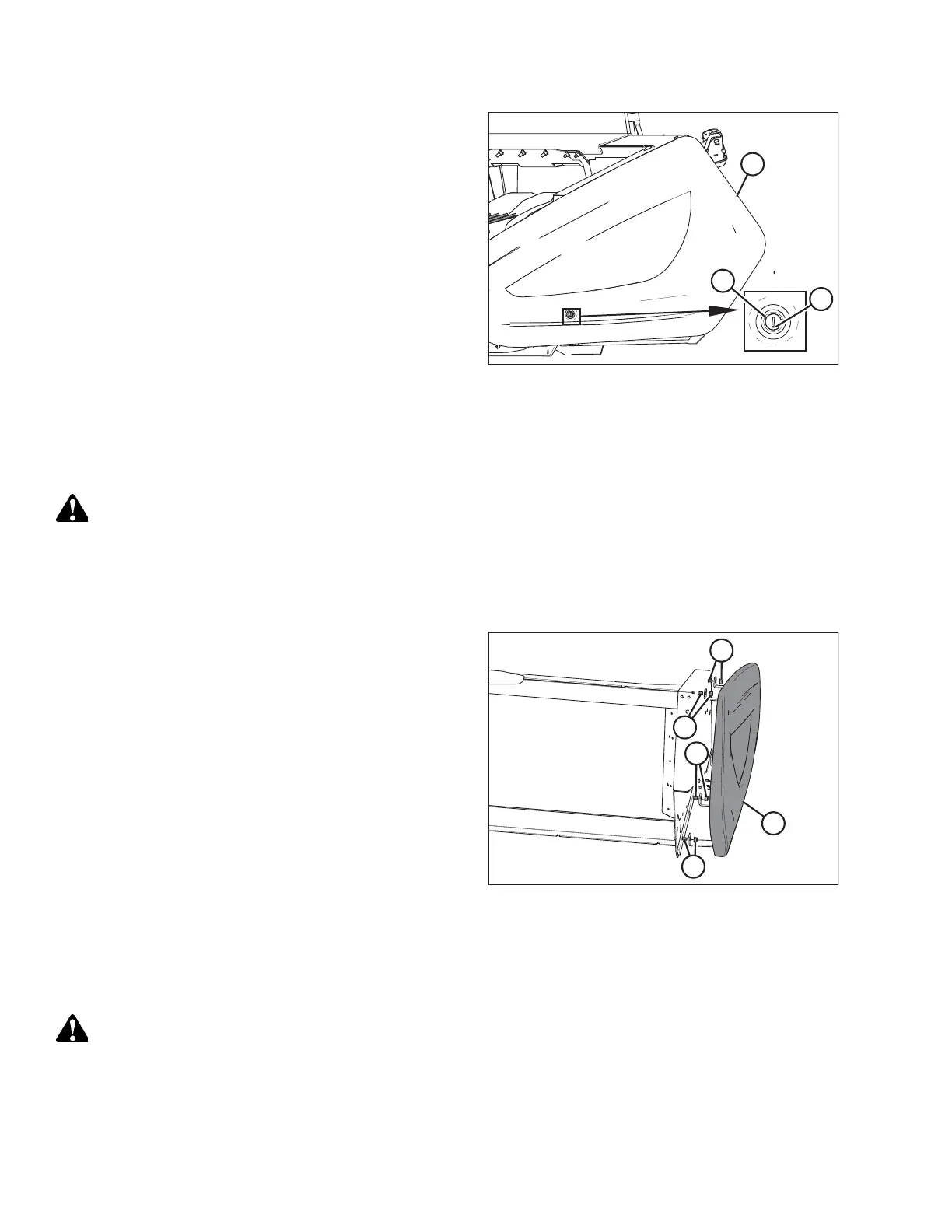

Figure 3.13: Endshield Closed

10. Close endshield (C) and use a slotted screwdriver to turn

latch (A) clockwise until it stops (slightly more than one

half turn).

NOTE:

When the latch is fully engaged, the slot will align with

notch (B), and the endshield will draw tightly against the

header.

11. Verify the following:

• The endshield is positioned against the header

endsheet.

• The endshield is aligned with the cutout in the frame.

• Latch (A) is engaged.

3.3.5 Removing Right Endshield

Remove the right endshield to gain better access to the right side of the pick-up header.

WARNING

To avoid bodily injury or death from unexpected startup of machine, always stop the engine and remove the key from

the ignition before leaving the operator’s seat for any reason.

1. Lower the header to the ground.

2. Shut down the header and remove the key from the ignition.

$

%

%

$

&

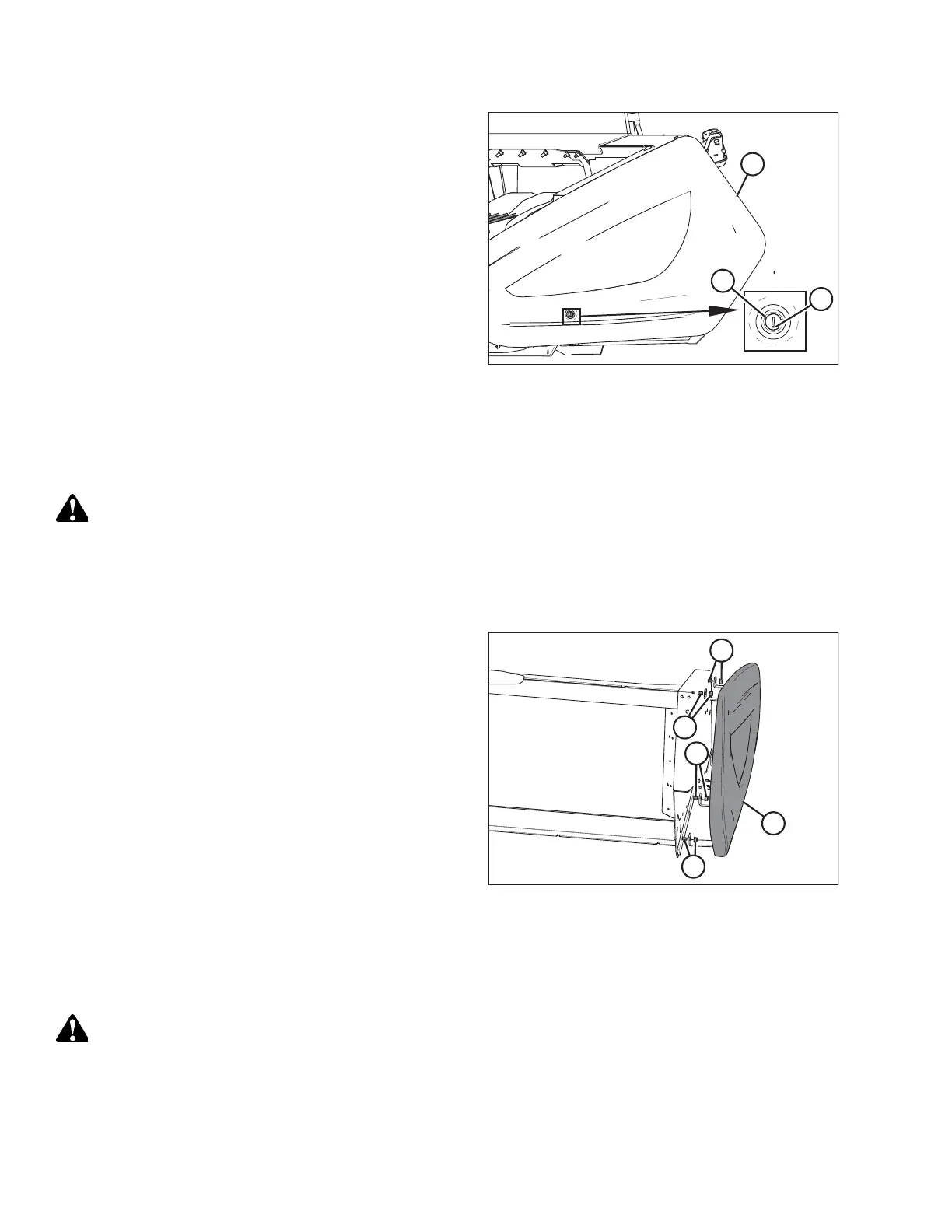

Figure 3.14: Right Endshield

3. Remove nuts and bolts (B) from the lower endshield

brackets on the header frame.

4. Remove nuts and bolts (A) from the upper endshield

brackets on the header frame.

5. Remove endshield (C) from the header frame.

3.3.6 Installing Right Endshield

Reinstall the endshield when you are done servicing the right side of the header.

WARNING

To avoid bodily injury or death from unexpected startup of machine, always stop the engine and remove the key from

the ignition before leaving the operator’s seat for any reason.

1. Lower the header to the ground.

2. Shut down the header and remove the key from the ignition.

OPERATION

Loading...

Loading...