215575 268 Revision B

$

%

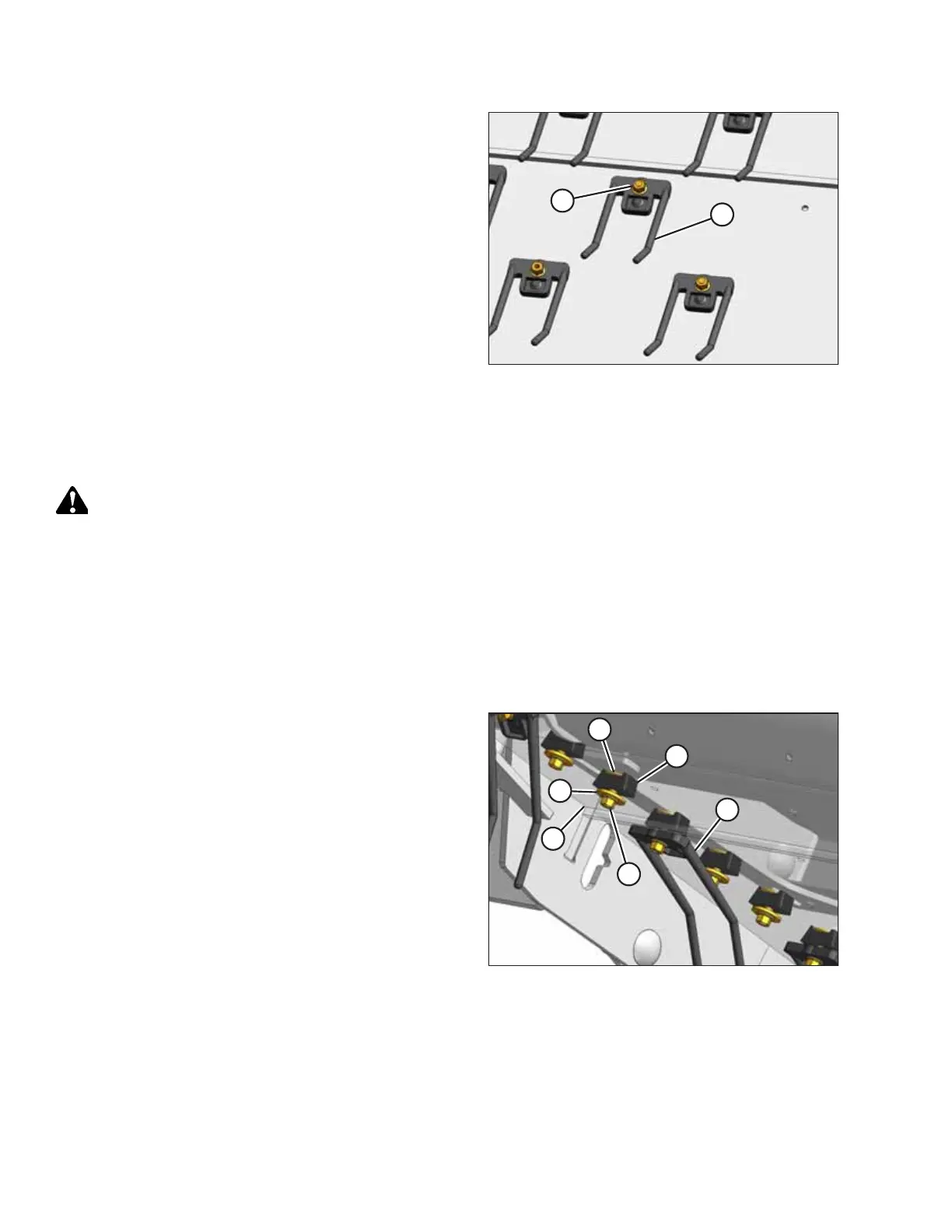

Figure 5.108: Draper Fingers

4. Remove M6 flange nut (A) securing finger (B) to the

draper belt.

5. Remove finger (B) and replace it with a new finger.

6. Secure the finger with M6 flange nut (A).

7. Torque flange nut (A) to 4–5.6 Nm (37 –50 lbf∙in).

NOTE:

Hold the finger to prevent it from turning while tightening

the nut.

Replacing Draper Guide

The draper guides can be accessed from underneath the draper belt.

DANGER

To avoid bodily injury or death from unexpected start-up or fall of a raised machine, always stop engine and remove

key before leaving the operator’s seat, and always engage safety props before going under the machine for any reason.

NOTE:

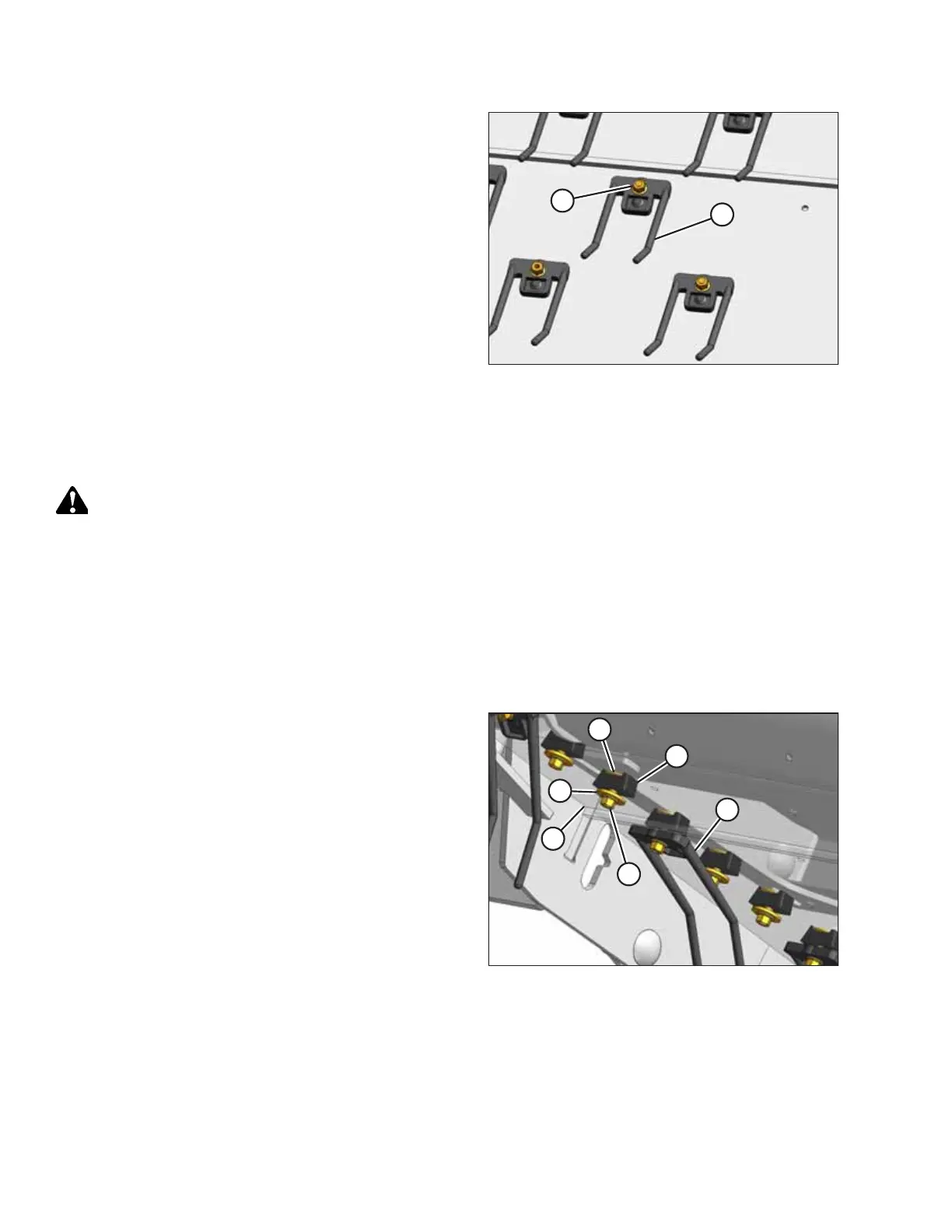

The illustrations in this procedure show the view from the lower left side of the pick-up header.

1. Raise the hold-down fully, and engage lift cylinder safety props.

2. Raise the header fully, and engage the combine lift cylinder safety props.

3. Stop the engine, and remove the key from the ignition.

$

%

&

'

(

)

Figure 5.109: Draper Guide

4. Fully release the tension on draper belt (D).

5. Pull draper belt (D) away from the frame from under the

deck to expose guide (C).

6. Remove M6 flange nut (A) and washer (B) securing guide

(C) to draper belt (D). If the guide is under a finger (for

example, finger [E]), remove the finger.

7. Remove guide (C) and elevator bolt (F). Discard the

old guide.

8. Place new guide (C) onto M6 x 26 elevator bolt (F) and

install the guide onto draper belt (D).

9. Install M6 washer (B) and flange nut (A).

MAINTENANCE AND SERVICING

Loading...

Loading...