215575 260 Revision B

5.7 Decks

The draper belts, their attached fingers and guides, and their roller bearings may require replacement or maintenance from

time to time.

5.7.1 Draper Belts

Periodically check the draper belts for signs of wear and damage. Replace draper belts that have stretched, have cuts or

tears, or have worn slats. Replace missing or damaged fasteners, damaged connector bars, and damaged straps.

Removing Front Draper Belt

The elevator bolts do not need to be removed if the front draper belt is not being replaced.

DANGER

To avoid bodily injury or death from unexpected start-up or fall of a raised machine, always stop engine and remove

key before leaving the operator’s seat, and always engage safety props before going under the machine for any reason.

1. Raise the hold-down fully and engage the lift cylinder safety props. For instructions, refer to 3.5 Engaging Hold-Down

Lift Cylinder Safety Props, page 33.

2. Raise the header fully, and engage the combine lift cylinder safety props.

3. Stop the engine and remove the key from the ignition.

4. Fully release the tension on the front draper belt.

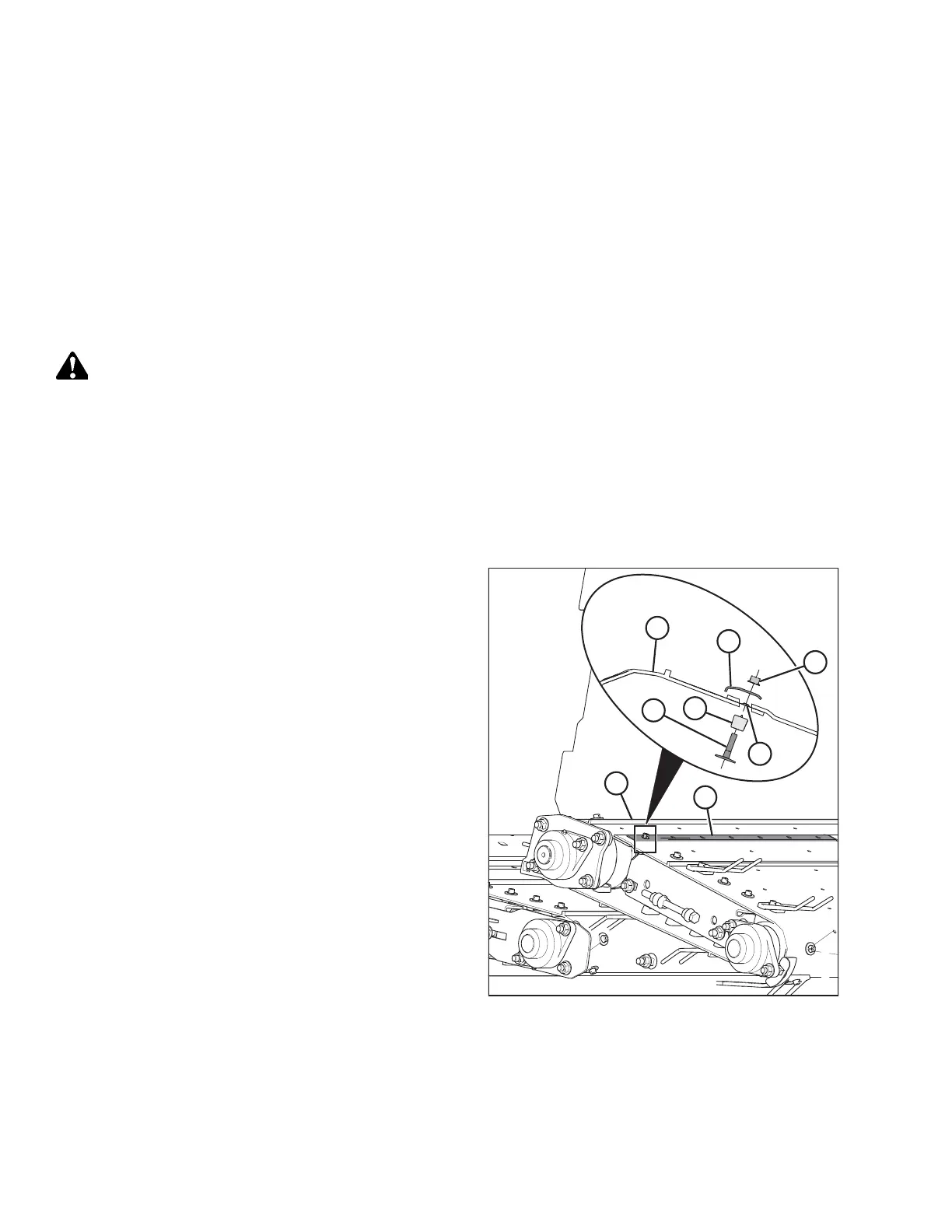

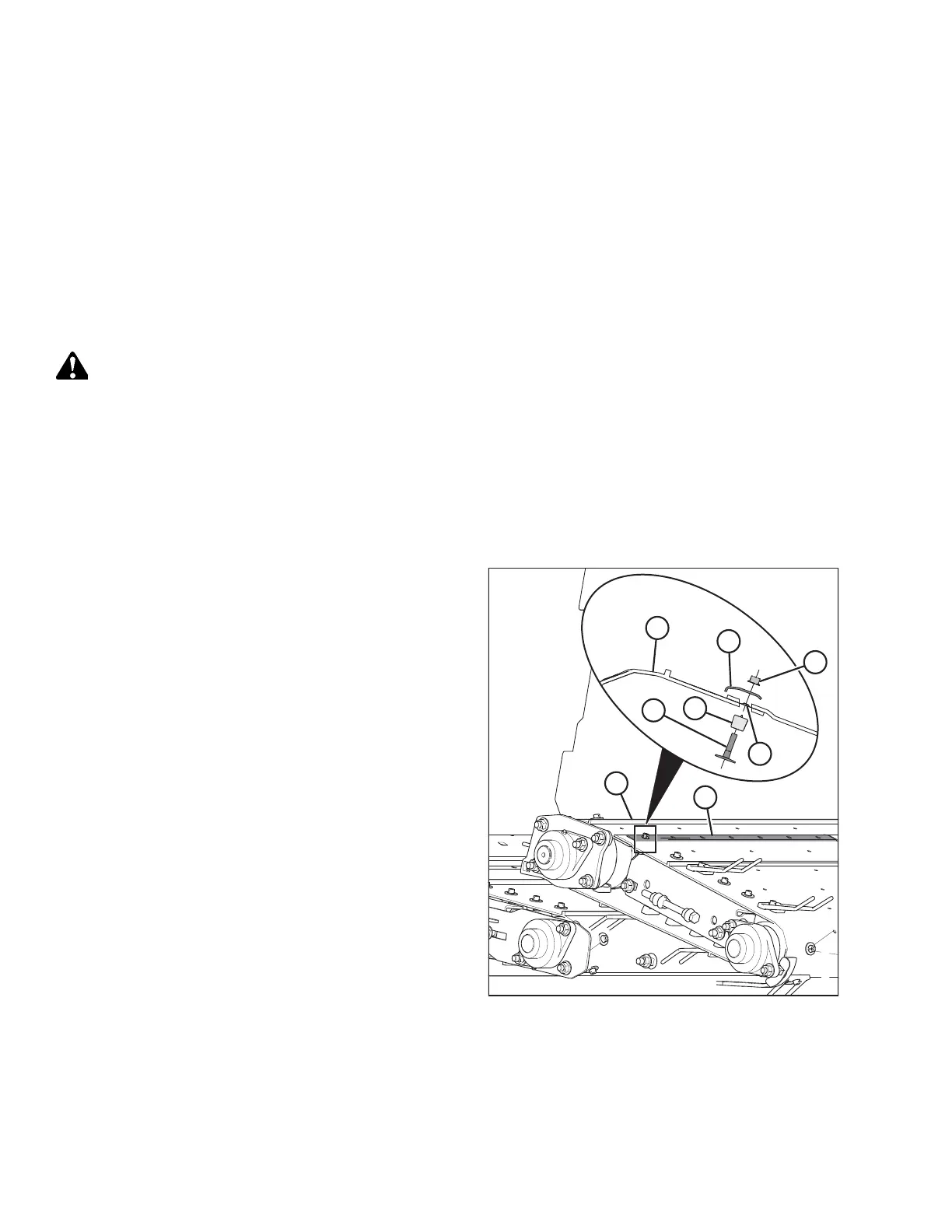

$

$

%

%

&

'

(

)

Figure 5.94: Front Draper Belt End

5. Rotate draper belt (A) until connecting belt edge

protector (B) is situated on top of the draper deck. Remove

and retain the following hardware:

• M6 flange nut (C)

• belt edge protector (B)

• retainer (D) (from between the draper overlap)

• guide (E)

• pronged elevator bolt (F)

NOTE:

Remove the elevator bolts only if you are replacing the

draper.

NOTE:

Parts have been removed from the illustration to show

clearly the removal order of the hardware and the draper

belt interior.

MAINTENANCE AND SERVICING

Loading...

Loading...