215575 292 Revision B

5.8 Header Spring Float Assembly

The header spring float assembly allows the header to move vertically to respond to the contours of the field being

harvested. Take note of the tension position of the header spring float assembly when removing or installing these

assemblies.

5.8.1 Removing Header Spring Float Assembly

Ensure that all spring tension has been released before working on the float assembly.

WARNING

To avoid bodily injury or death from unexpected startup of machine, always stop the engine and remove the key from

the ignition before leaving the operator’s seat for any reason.

1. Attach the header to the combine feeder house and ensure that it is latched securely. It is not necessary to hook up

the driveline or the hydraulics. For instructions, refer to 3.10 Header Attachment and Detachment, page 38.

2. Lower the combine feeder house so that the front draper deck is rotated upward to the full floated-up position. The

header frame will be close to the ground and the coil spring will be fully collapsed.

NOTE:

The spring tension is factory-set to the second hole from the bottom on the float anchor.

3. Shut down the engine, and remove the key from the ignition.

$

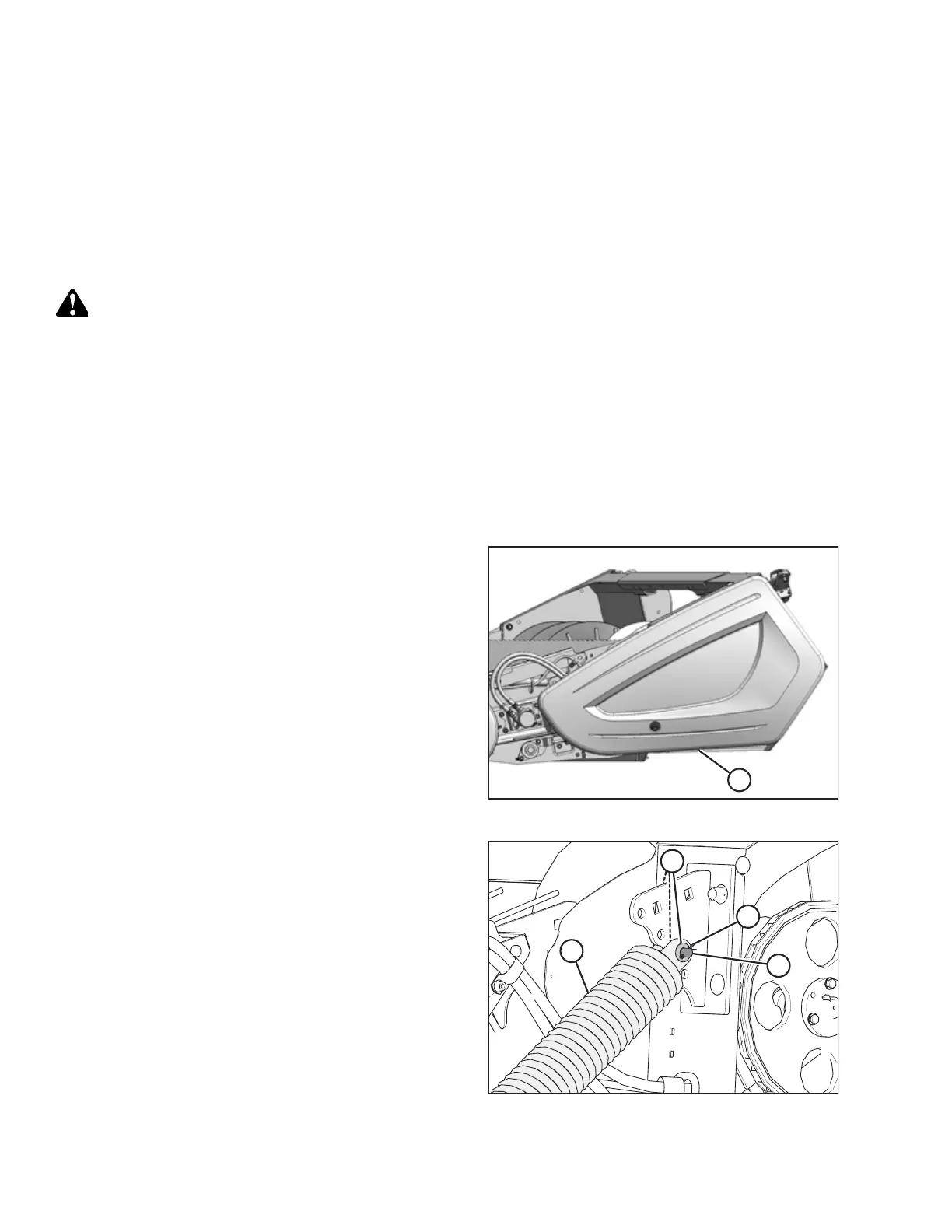

Figure 5.167: Left Endshield

4. Open left endshield (A). For instructions, refer to 3.3.1

Opening Left Endshield, page 25.

NOTE:

The right spring float assembly can be removed or adjusted

without removing the right endshield. For improved

accessibility, however, remove the right endshield. Refer to

3.3.5 Removing Right Endshield, page 30 for instructions.

$

%

&

'

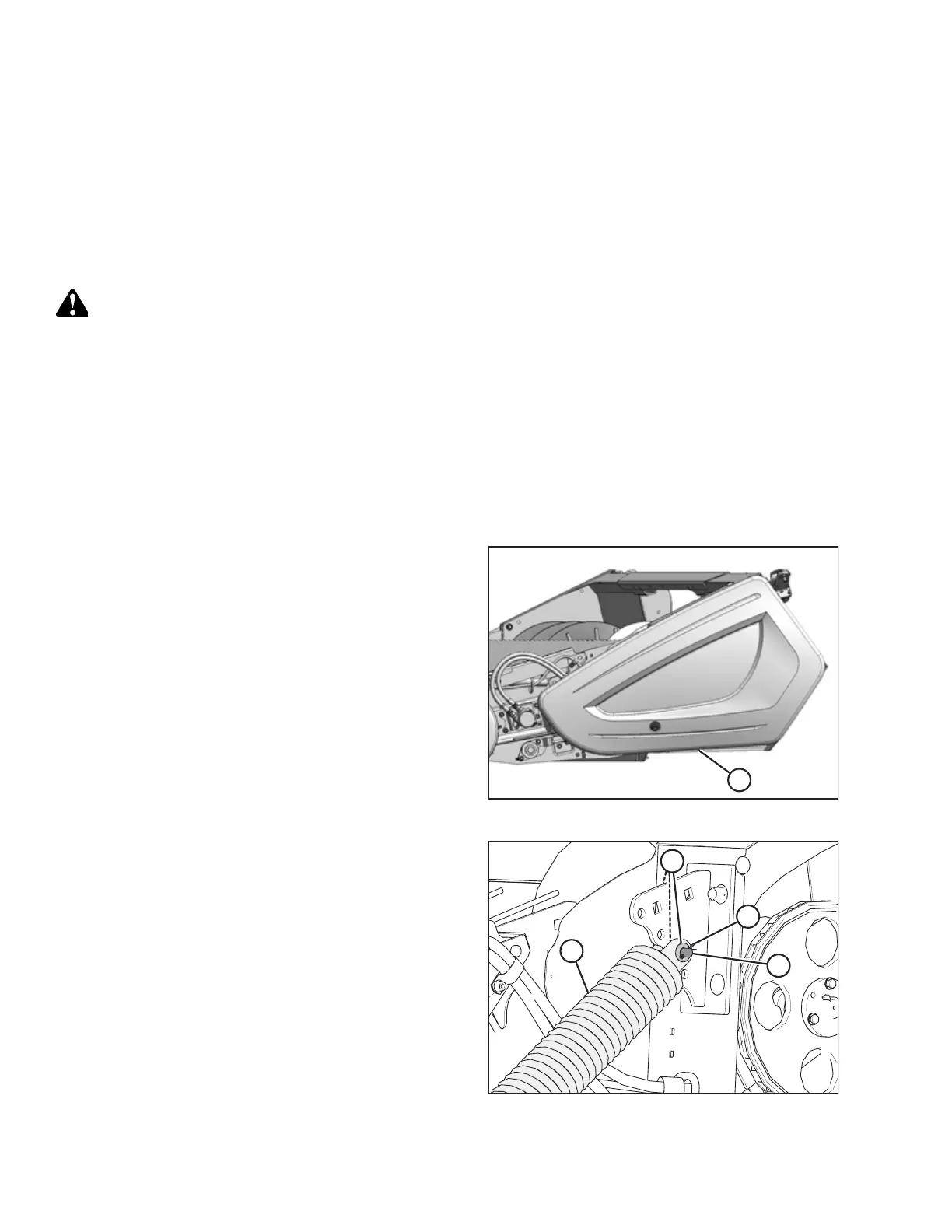

Figure 5.168: Left Spring Float Assembly

5. Ensure that all spring tension is released from left spring

float assembly (A). Remove cotter pin (B), clevis pin (C), and

three flat washers (D).

NOTE:

When the spring tension is fully released, the spring coils

should be fully collapsed and the spring float assembly

should rock from side to side when moved by hand. If

pressure on the clevis pin persists, slightly raise or lower

the header.

MAINTENANCE AND SERVICING

Loading...

Loading...