CHARGING SYSTEM - 4C-1390-823225--1 1096

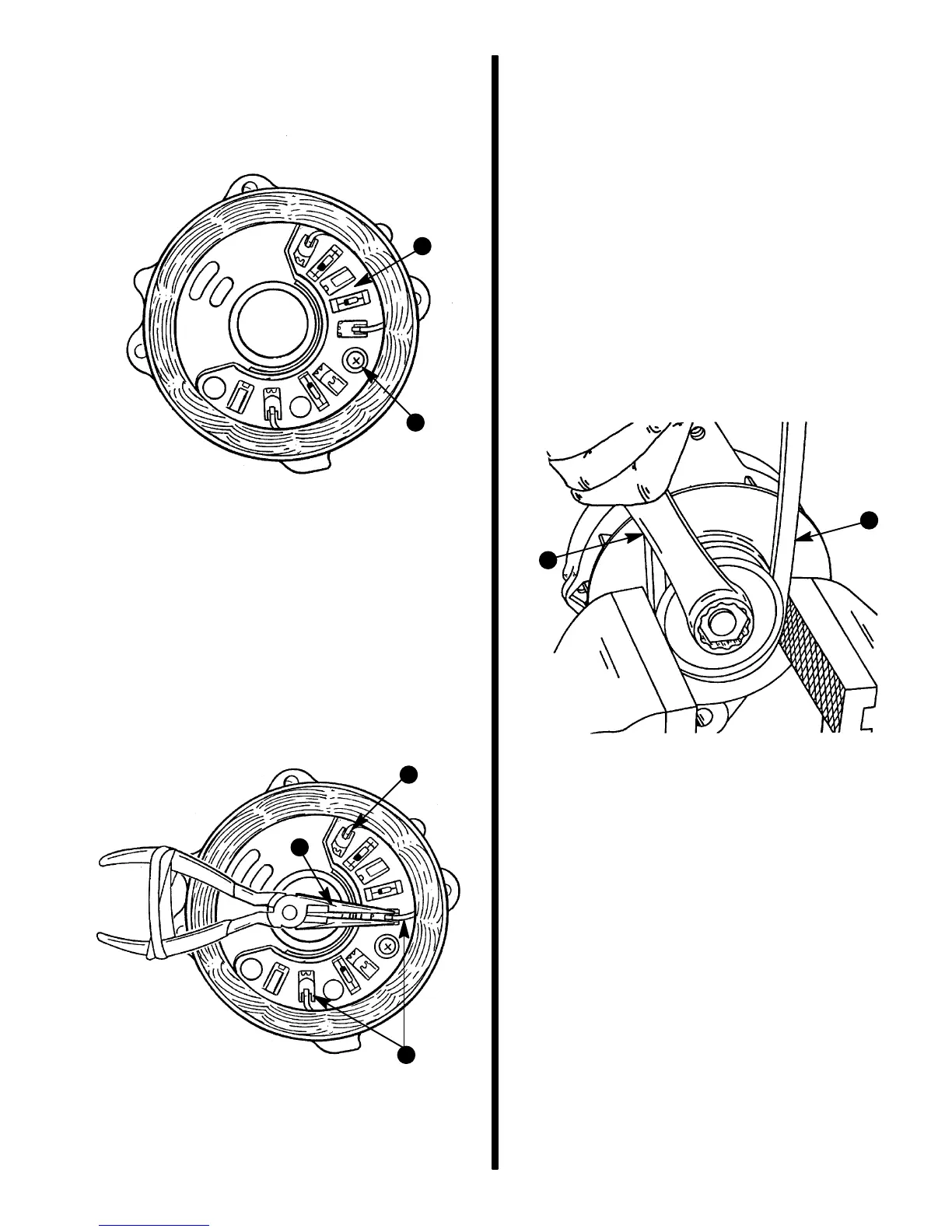

9. Turn end frame over (stator upward) and remove

one Phillips head screw which secures rectifiers

to end frame.

72826

b

a

a - Rectifier Assembly

b - Phillips Head Screw

10. Separate stator and rectifier assembly from rear

end frame using screwdriver slots.

11. Unsolder the three stator leads from the rectifier

heat sink. Place a needle nose pliers on diode ter-

minal between solder joint and diode body to help

prevent heat damage to diodes. Unsolder joints

as quickly as possible and allow diode terminal to

cool before removing pliers.

72827

a

b

b

a - Heat Sink

b - Stator Leads (3)

IMPORTANT: With alternator disassembled to

this point, stator, rectifier, diodes, and rotor may

be tested, as explained under “Component Test-

ing,” following.

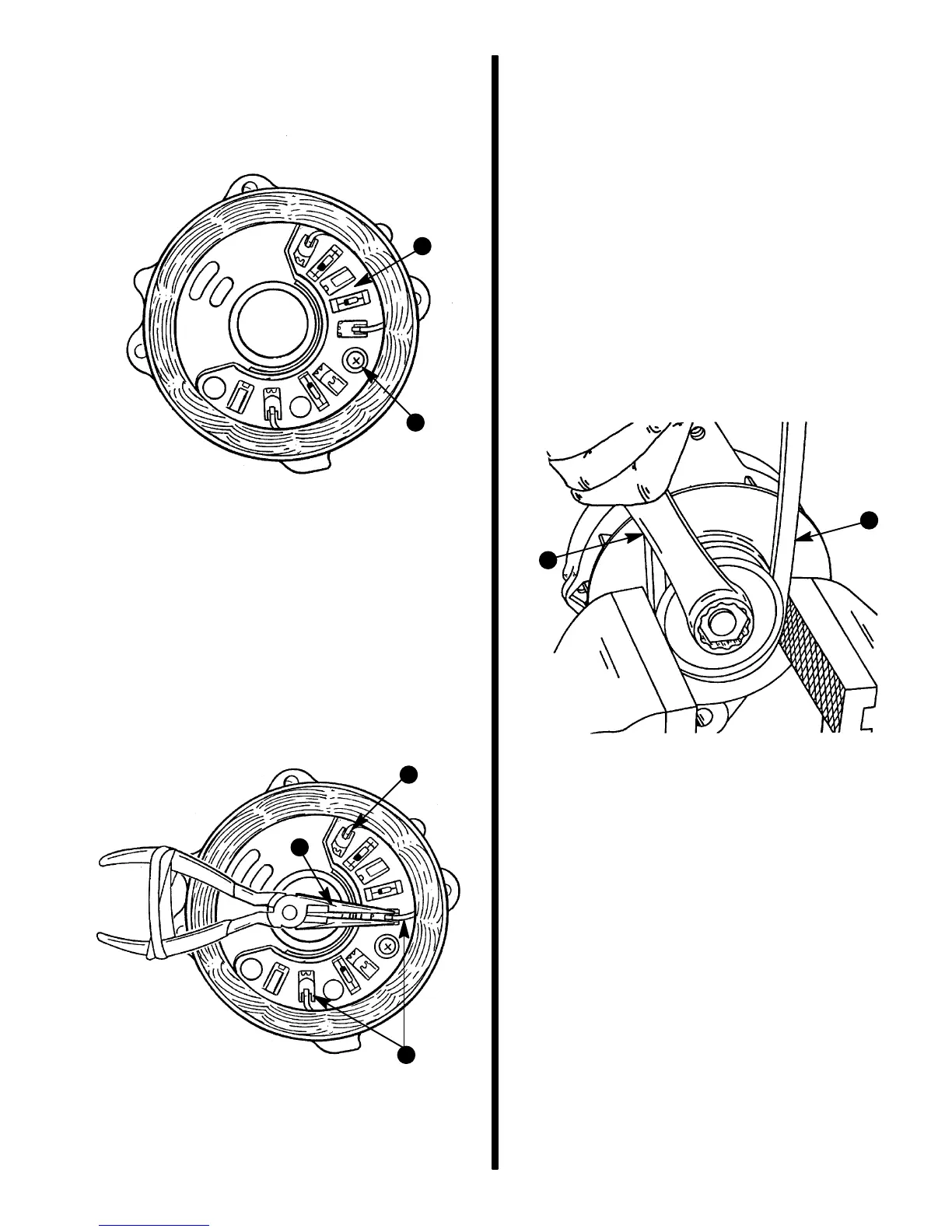

IMPORTANT: DO NOT clamp vise on rotor pole

pieces when removing pulley nut (in next step),

as pole pieces may be distorted.

12. Remove pulley retaining nut by clamping pulley

in a vise (using an oversize V-belt or protective

jaws to protect pulley) and turning nut counter-

clockwise with a wrench. Remove lockwasher

and slide pulley and fan from shaft. If pulley is dif-

ficult to remove, it may be necessary to use a uni-

versal puller.

72828

b

a

a - Wrench

b - Over-Sized Belt To Protect Pulley

Loading...

Loading...