— 10-2 —

10.3. Periodic Check

10.3.1. Motor

!

Caution : Never disassemble the Motor and the resolver.

The table below shows the checklist of periodic maintenance. The checking interval shown in

the table is for reference only. It should be decided according to the actual use conditions and

environment.

You do not require replenish the grease of the bearing.

We cannot repair the Motors at the User’s site regardless of the level of failure. If any problem

was found by the periodic check, please consult with NSK sales or representative.

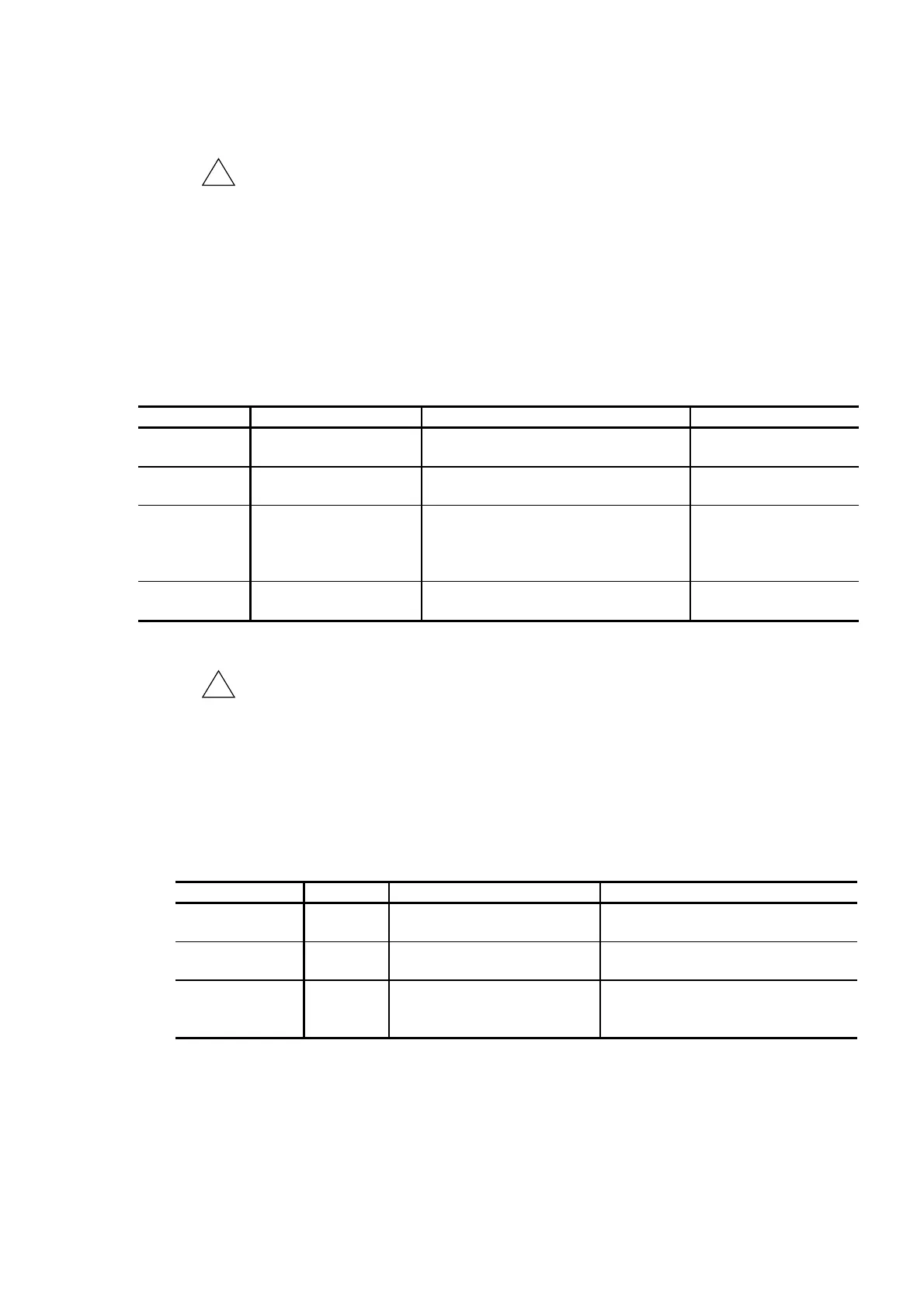

Table 10-2: Periodic Check of Motor

Item Checking interval How to check Remarks

Vibration/Noise

Daily

• Hearing

• No difference with

normal state.

Appearance

Depending on the degree

exposed to contamination

• Wipe off or blow off contaminants.

–

Insulation

Once a year

• Disconnect the Driver Unit, then check

the resistance between the Motor coil

and the ground earth with a 500v

megohmmeter.

• Resistance ≥ 2 MΩ

Refer to “Appendix 2.”

Play in bearing

Once a year

• Apply repetitive moment load less than

the limit, and feel play of the bearing.

• No play by the feel.

10.3.2. Driver Unit (Including Cables and Handy Terminal)

!

Caution : Do not disassemble the Driver Unit.

• High residual voltage may exist inside the Driver Unit for a while after

the power is turned off.

(In such a case, “CHARGE LED” is on.)

The daily check of the Driver Unit is not necessary because of the use of highly reliable

semiconductors. The checks shown in Table 10-3 require at least once a year.

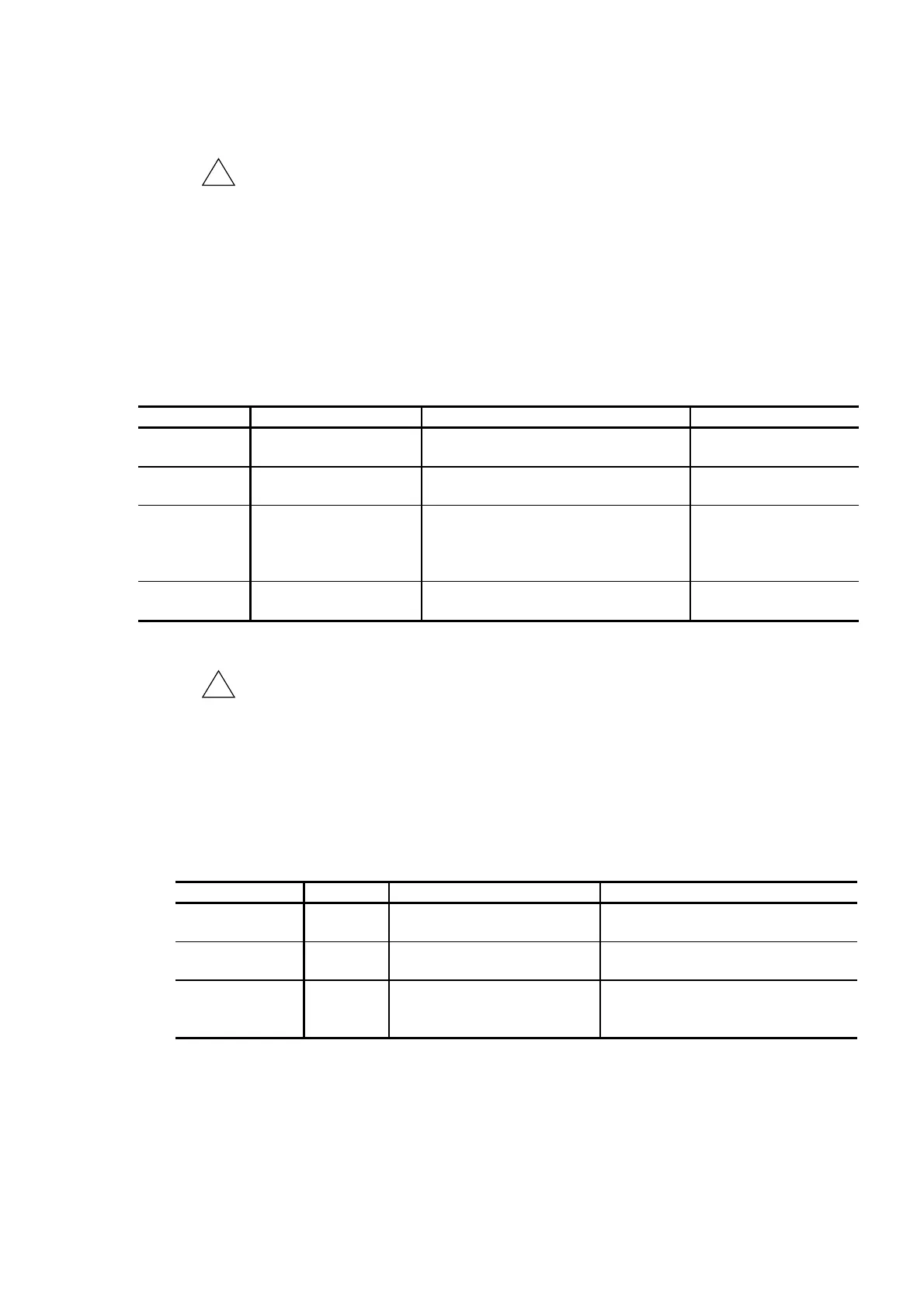

Table 10-3

Item Interval Checking point Remarks

Retighten

screws

Once/year

Terminal block screws.

Connector fixing screws.

–

Cleaning

Once/year

Remove dust or contaminants

outside of Driver Unit.

–

Cable check

Once/year

Visually check any damages or

cracks.

Especially when you force to bend and

twist the cables, increase the checking

interval depending on the conditions.

Loading...

Loading...