— 11-9 —

11.3.3. Alarm A1: Position Data Error

When the control power of the Driver Unit is turned on, the System checks the absolute position

of the Motor.

This alarm reports that the checking of Motor position does not have properly executed because

the Motor moved when the control power was turned on.

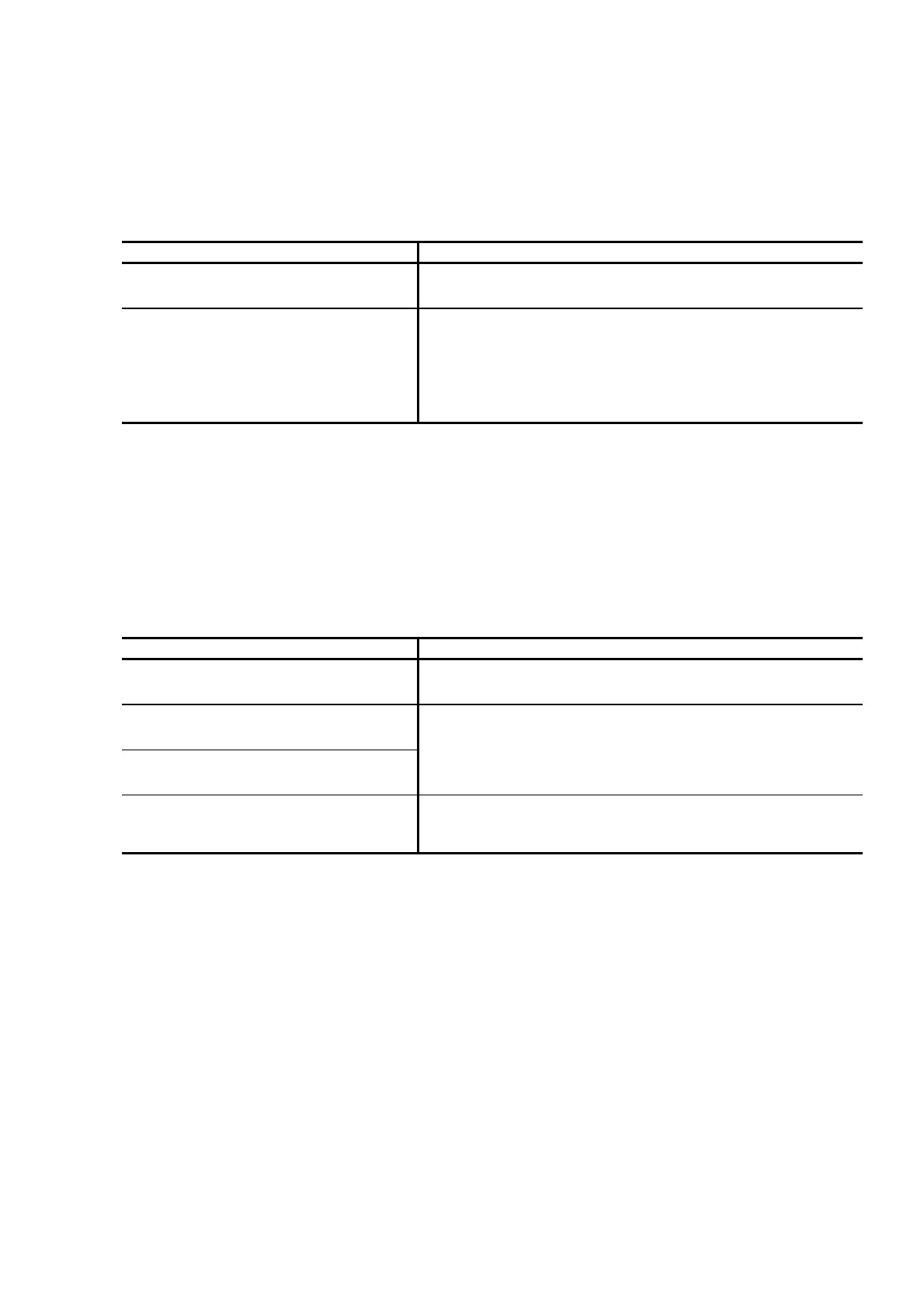

Table 11-10: Cause and remedy for the alarm A1

Cause Remedy

(1)

The Motor moved when the

power is on.

• Reset the power (Off → On).

(2)

Defective cable, Motor, or Driver

Unit. .

• Follow the checking described in “Appendix 2: How to Check

Motor Condition” to check the Cables and the Motor. Replace them

if necessary.

• If above check is not satisfactory, it may require replacing the

Driver Unit. Refer to “Appendix 4: Procedure for Replacing the

Driver Unit,” and replace it.

(1) If the Motor moves because of motion of other unit and thus the alarm occurs, change the timing

of turning on the control power of the Driver Unit.

11.3.4. Alarm A2: Motor Cable Disconnected

The Driver Unit supplies to the Motor winding for its rotation.

The alarm occurs when the current does not flow through the Motor winding even the command

for the Motor motion has been inputted, and thus detects a break in the motor cable.

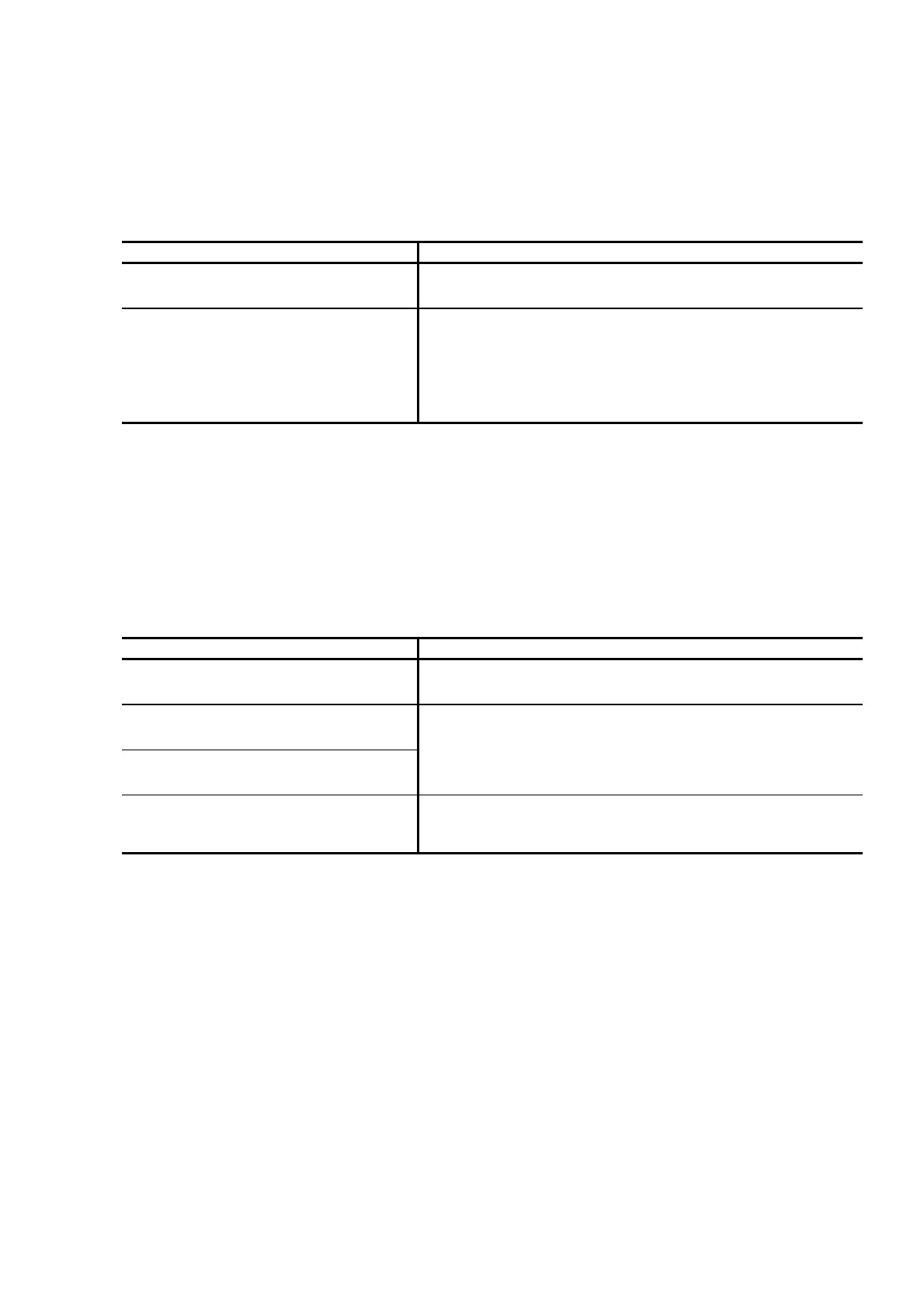

Table 11-11: Cause and remedy for the alarm A2

Cause Remedy

(1) Motor cable disconnected.

• Check the Motor cable for proper connection.

(2) Defective Motor cable

(3) Defective Motor winding

• Visually check the cable for damage.

• Replace the Motor or the Motor cable if necessary. Refer to

“Appendix 2: How to Check Motor Condition”.

(4) Defective Driver Unit

• If it does not recover with above measures, the Driver Unit may be

defective. Replace it referring to “Appendix 4: Procedure for

Replacing the EDC Driver Unit,” if necessary.

(1) Refer to “2.6.3. Cable Set” for the bending radius of the Motor cable. Refer to “2.6.1. PS Series

Megatorque Motor” for the Motor cable that is integrated with the Motor.

A too far small bending radius may cause a break in the cable.

(2) Do not fix the cable in the way that results in the force concentration on one area because it may

cause a cable break.

(3) When tie wrap the cables, be careful not to tie them tightly. Otherwise it may break inside of the

cables, even their outside look normally.

(4) When the cables are put in a cable carrier, the share of total cables shall be equal to or less than

50% of the inside area of a cable carrier. Do not put too much cable in it. Otherwise damage on

the cable coating may occur and may lead to internal cable break. Fix the cable to the cable

carrier at its entry and exit so that the force to the connecters is minimal.

Loading...

Loading...