— 5-2 —

5.2. Tuning Level 1: Automatic Tuning

!

Caution : The automatic tuning does not function if the following conditions are

not met. Confirm them before carrying out the automatic tuning.

• The load moment of inertia must be in the allowable range of the Motor. Refer

to “3.2.1.4. Confirmation of Use Conditions.”

• The Motor is set horizontally. (The load condition of the Motor must not be

affected by external force such as the gravity.)

• Mechanical rigidity of the Motor mounting base and an attached load to the

Motor is sufficient enough.

• There must be no backlash or play caused by gears or couplings.

• Frictional load to the Motor shall be minimal.

If the above conditions are not met, proceed to “5.3. Tuning Level 2:

Servo Gain Tuning.”

Preparation

You need to prepare the following for the automatic tuning.

◊ Installation of the Motor. (Refer to “3.2.1.2. Motor Installation.”)

◊ Attach the load to the rotor of Motor. (Refer to “3.2.1.3. Coupling Load to Motor.”

◊ Installation of the Driver Unit. (Refer to “3.2.2. Installation of Driver Unit.”

◊ Connection of the Motor and the Driver Unit. (Use the cable set provided with the

Driver Unit.) Refer to “3.3.1.Connection of Cable Set.”

◊ Connection of the Handy Terminal.

◊ Connection to AC power source. Refer to “3.3.2. Connecting Power.”

◊ Wiring Servo ON (SVON) and Emergency stop (EMST) signal circuits.

(Connector CN2) Refer to “3.3.4. Connector Wiring.”

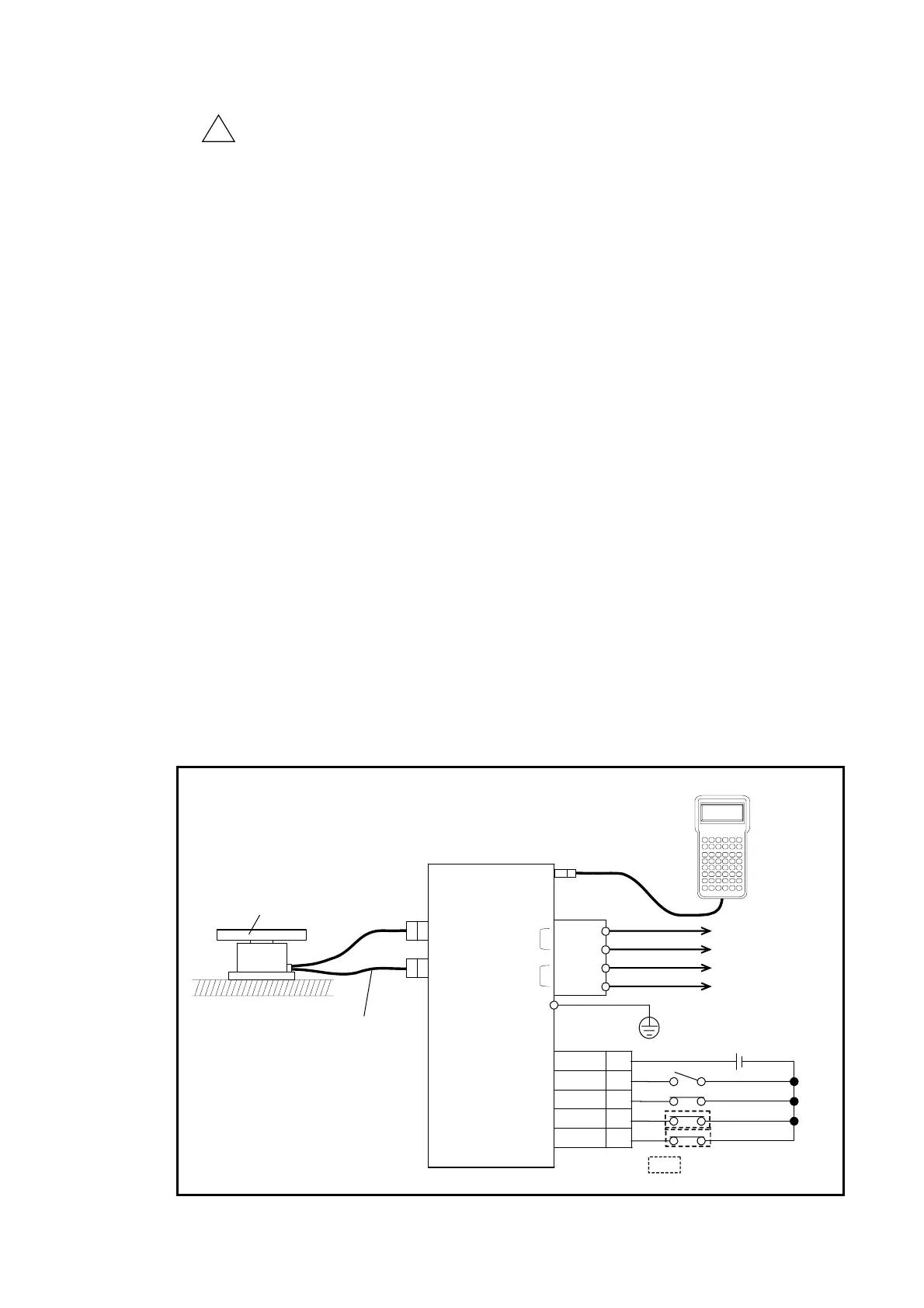

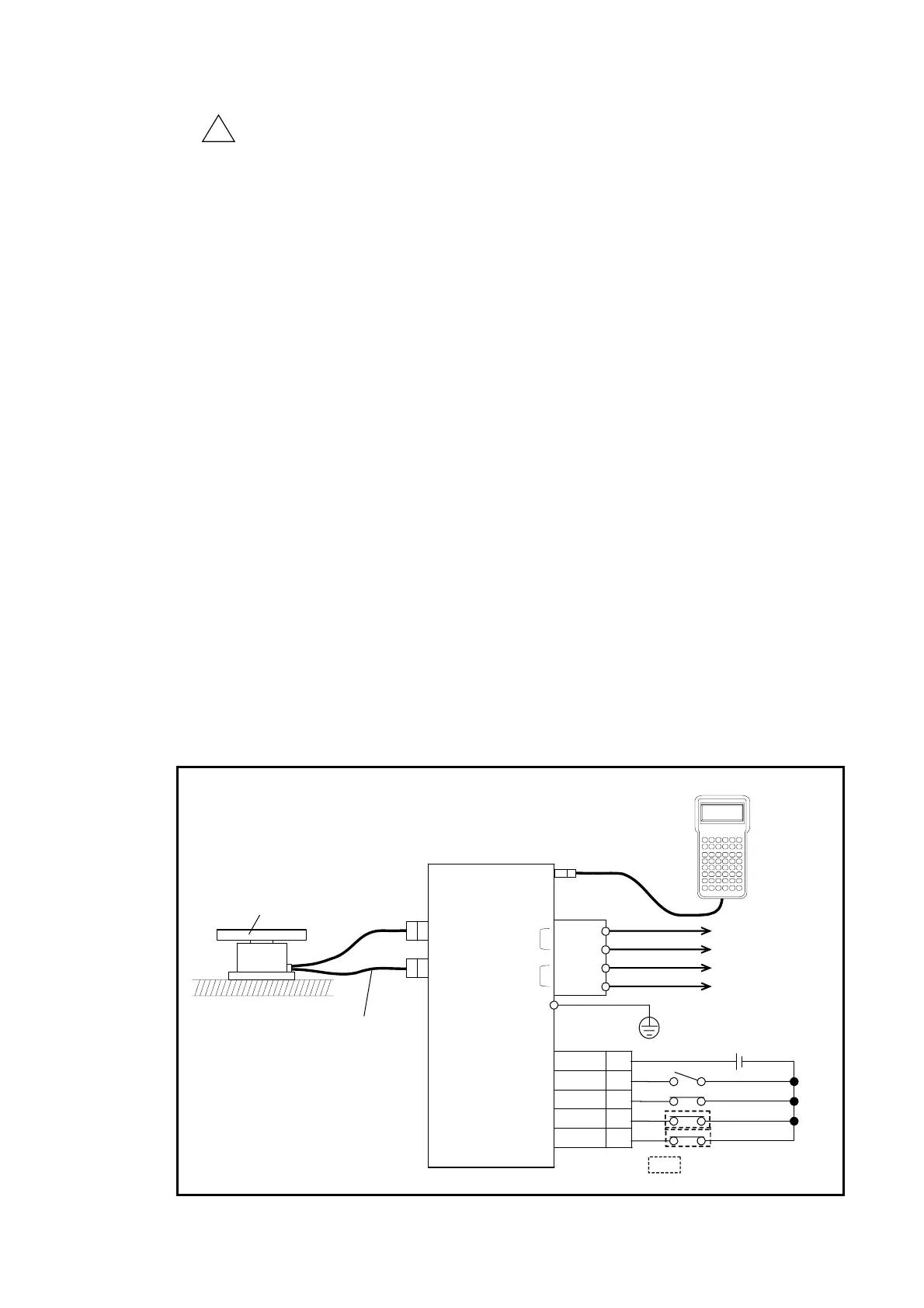

Fig 5-2: Wiring example of automatic tuning setup (reference only)

CN1

CN5

CN4

Contorl

power

CTRL

CN3

Main

power

MAIN

PE

DC24 1,2

SVON 7

CN2 EMST 3

OTP 5

OTM 6

Mounting base

Work or attachment

(Load inertia)

AC power

Handy Terminal

24 VDC

(External power supply)

Cable set

Motor

Over travel limit sensors

AC power

3

<

2

$

1

#

-

+

5

%

4

>

8

(

7

‘

6

&

.

=

0

?

9

)

CBA FED

IHG LKJ

ONM RQP

UTS XWV

?ZY */,

CTRLESCSHIFT ENTSPBS

NS

HANDY TERMINA L

Loading...

Loading...