— 12-3 —

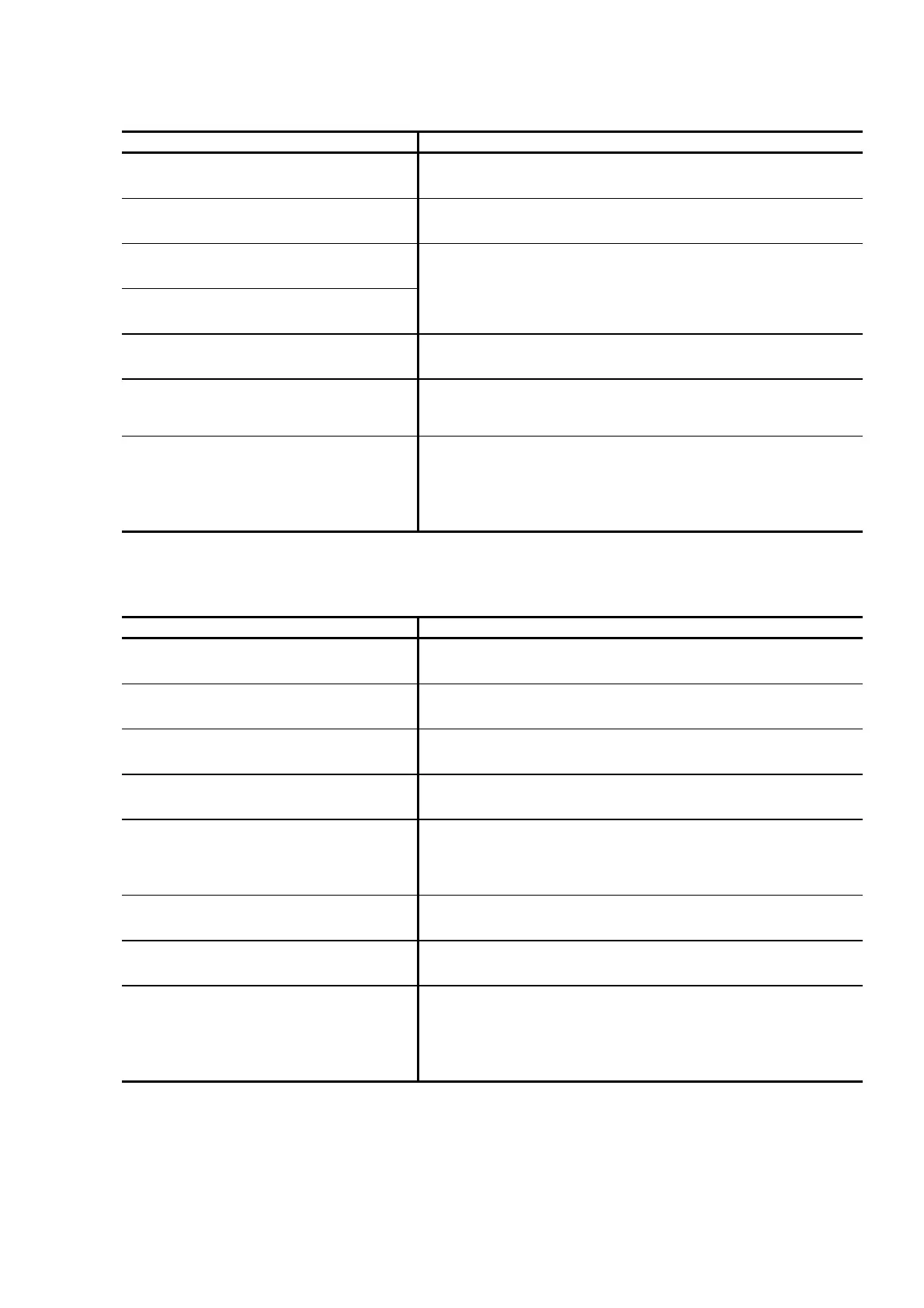

12.2.3. Vibration, Abnormal Noise or Unstable Settling

Table 12-5: Troubleshooting for vibration, abnormal noise and unstable settling

Cause Remedy

1)

Wrong combination of Motor and

Drive Unit.

• Check if the combination of the Motor and the Driver Unit is

correct.

2)

Loose mounting of the fixture and/or

the Motor

• Check for loose mounting of the fixture and the Motor.

3) Poor setting of the servo gains

4) Mechanical resonance.

• Refer to “5. Tuning” for adequate tuning.

5)

Low rigidity of the total mechanical

system.

• Refer to “5. Tuning” for adequate tuning.

• If the problem remains, review the rigidity of the total mechanism.

6)

Overload or interference with the

mechanical system of the

equipment.

• Remove the external interference.

7)

Defective Cable, Motor, and/or

Driver Unit.

• Refer to “Appendix 2: How to Check Motor Condition” and check

the cable and the Motor.

• If no failure is found in the Cable and the Motor, the Driver Unit

may be defective. Replace it referring to “Appendix 4: Procedure

for Replacing the EDC Driver Unit.”

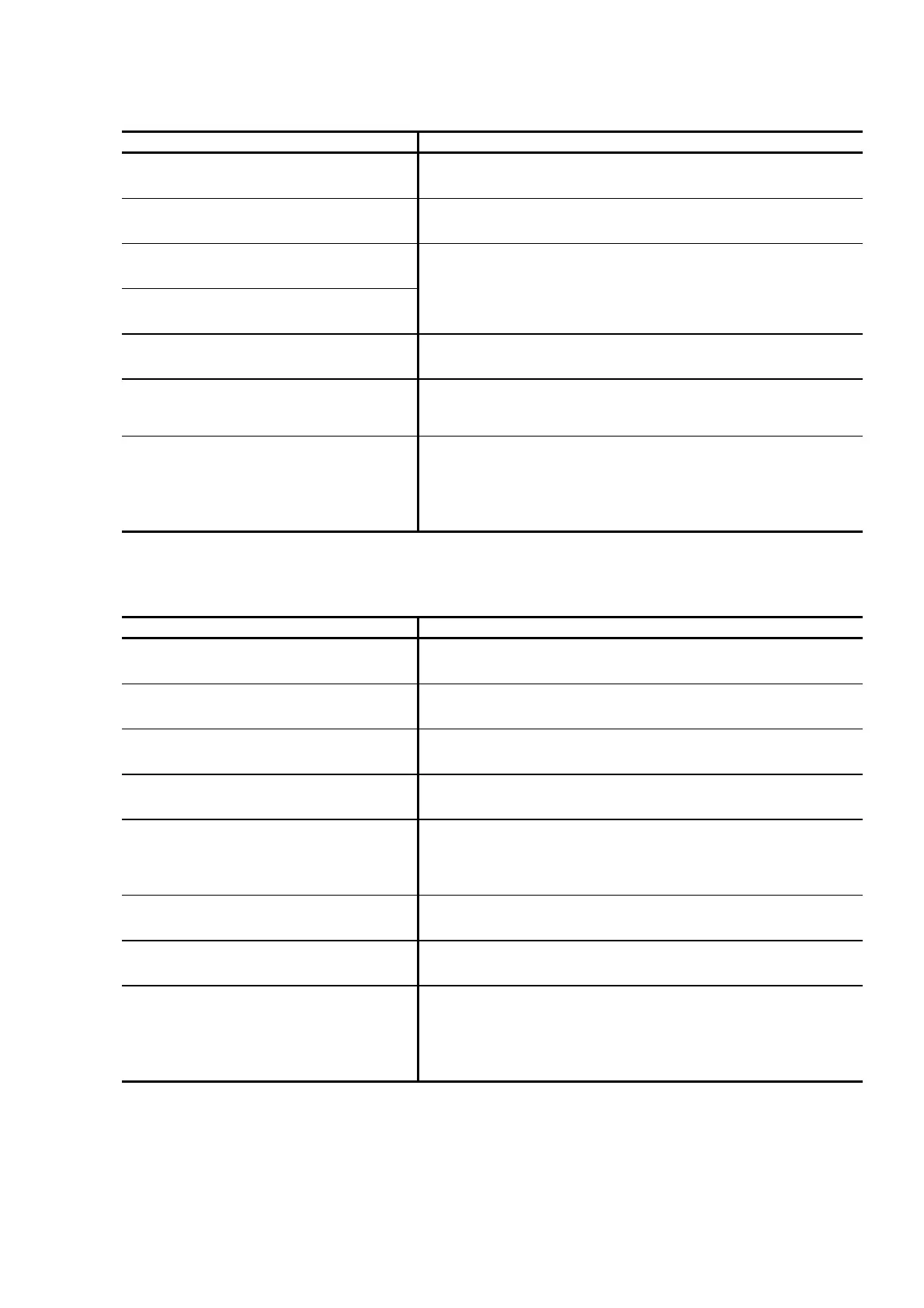

12.2.4. Improper Positioning

Table 12-6: Troubleshooting for improper positioning

Cause Remedy

1)

Wrong combination of Motor and

Driver Unit.

• Check if the combination of the Motor and the Driver Unit is

correct.

2) An alarm or a warning is occurring. • Identify the alarm or the warning.

3)

Loose mounting of the fixture and/or

the Motor.

• Check for loose mounting of the fixture and the Motor.

4) Poor setting of the servo gains. .

• The positioning accuracy is poor even the IPOS signal is closed.

• Review the tuning state of the servo related gains.

5)

Overload and/or an excessive

friction load to the Motor due to the

mechanical interference with the

surrounding mechanism.

• Remove the external interference.

6)

External noise interferes in the pulse

train command signal.

• Take measures against the external noise.

7)

An objective program channel is not

selected in the program operation

• Use the monitor IO0 (Input/output monitor 0) to confirm if the

objective channel is selected.

8)

Defective Cable, Motor and/or Driver

Unit.

• Refer to “Appendix 2: How to Check Motor Condition” and check

the cable and the Motor. Replace them if necessary.

• If no failure is found in the Cable and the Motor, the Driver Unit

may be defective. Replace it referring to “Appendix 4: Procedure

for Replacing the EDC Driver Unit.”

Loading...

Loading...