— 6-1 —

6. Operation

6.1. Preparation

6.1.1. Wiring Check

!

Caution : On completion of wiring the EDC Driver Unit, check the items listed in

Table 6-1 before operating the Megatorque Motor System.

Table 6-1

No. Items to be checked Points to be checked

1

Connection of main power

and Input/Output signal

cables

• Check if the wiring is properly done.

• Check if the screws of the ground terminals are securely fastened.

• Check if the connectors are properly connected and secured.

2

Connecting cables

• Check if the Cable Set (Motor cable and resolver cable) are properly

connected and locked to the connectors.

3

Handy Terminal

• Check if the Handy Terminal is connected properly, and locked to

the CN2 connector.

6.1.2. Operation Procedure

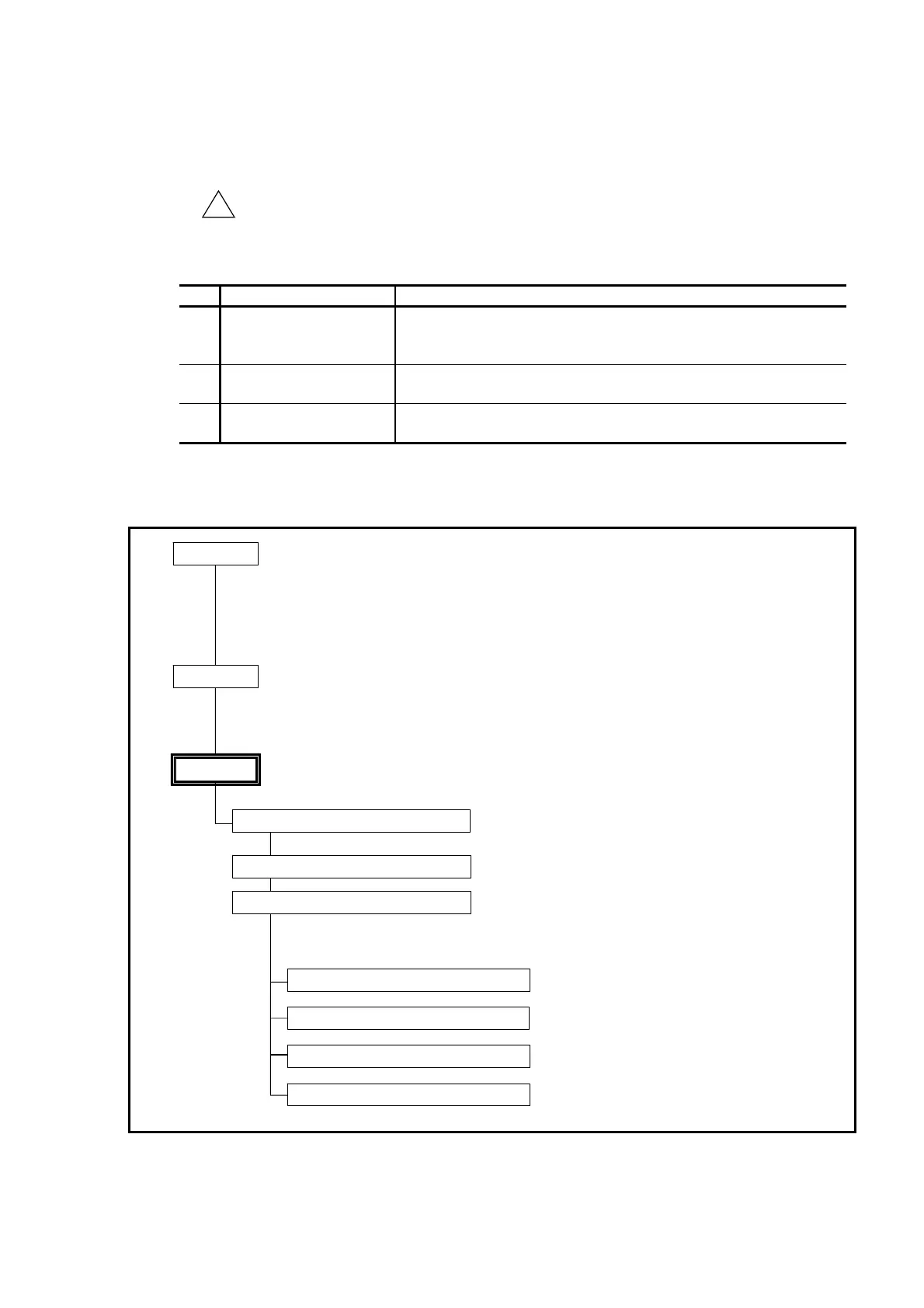

Fig 6-1

• Check for the power voltage (main power and control power).

• Turn on the power, then confirm that the power LED (green) and the 7 segments LED on the

front panel of the Driver Unit are indicating normal state.

• Confirm that the display of the Handy Terminal shows the screen for initial setting.

Power on

• Refer to “5. Tuning.”

Tune the servo parameters. Skip this part if all tuning have been completed in advance.

Tunin

RS-232C command positioning

6.3.3. Pulse Train Command Positioning

6.3.4. Jogging

6.3.2. Program Positionng Operation

6.3.5. RS-232C Communication

Positioning Operation

6.2.3. Setting Home Position

Program positioning

Positioning by pulse train

Jogging

6.2.2. Direction of Position Scale

6.2.4. Software Travel Limit

Operation

Set the direction of position scale.

Set the Home position.

Set the software travel limits.

Loading...

Loading...