— 12-1 —

12. Troubleshooting

12.1. Identifying Problem

If problems have been occurred, check the items shown in Table 12-1. When reporting problems

to the NSK sales or representative, the explanation of the items in Table 12-1 will help us to

identify them.

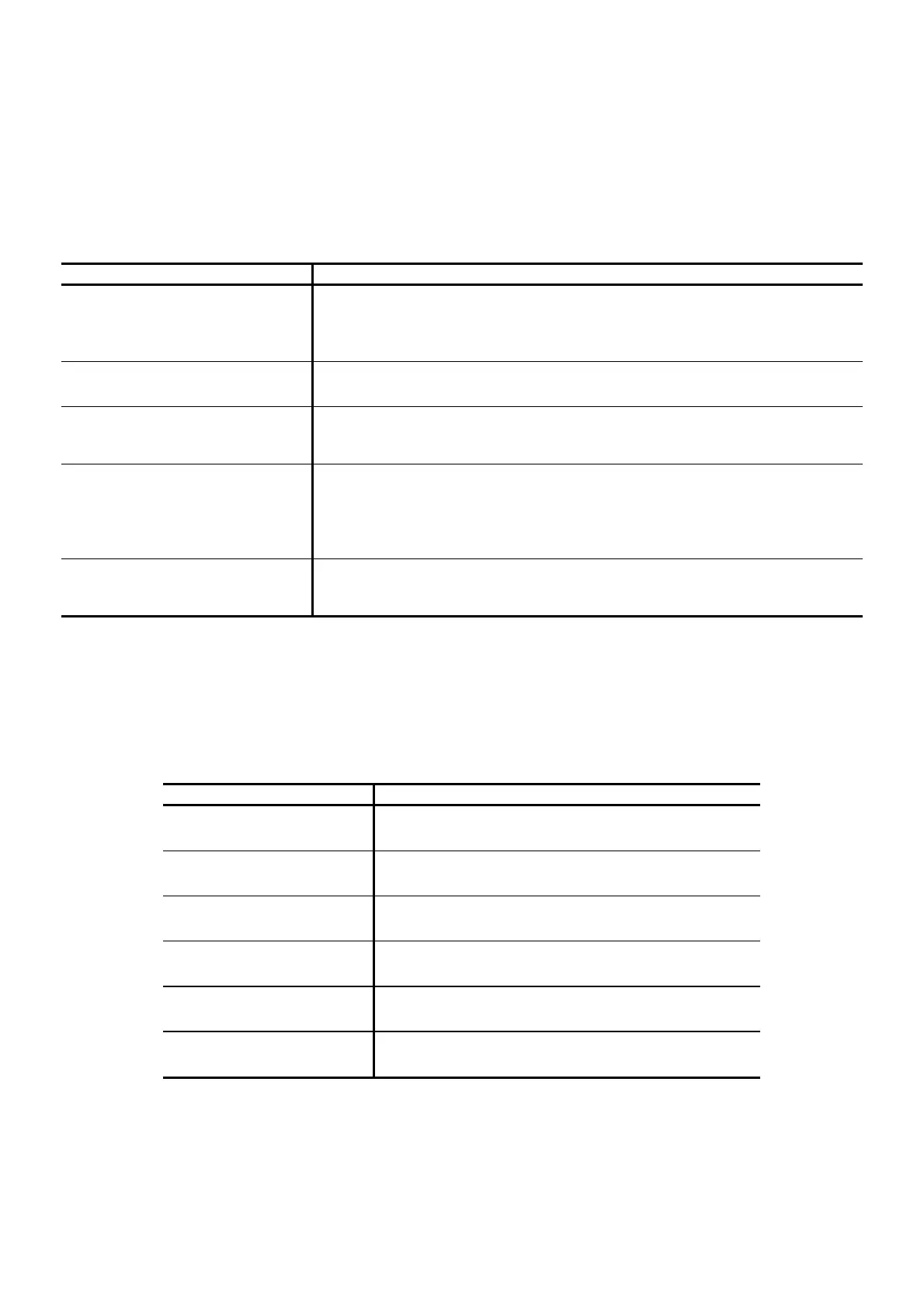

Table 12-1: Items to be checked when a problem occurs

Items Point to be checked

1)

Check the combination of the

Motor and the Driver Unit

• Check if the following items on the nameplates of the Motor and the Driver Unit

conform to each other: the Motor series code, the Motor size number, and the

Maximum torque code.

• Refer to “3.1.2. Combination of Motor and Driver Unit” for details.

2) Power source voltage • Check the voltage variation of the power source.

3) Trouble recurrence

• Confirm the frequency of occurrence.

[Example]: Once/ every one hour

Several times/week

4)

Occurrence in special

occasion

• At what particular occasion does the problem occur?

[Example]

• When welding process is performed in the proximity.

• When the Motor is accelerating.

• Occurs at the same position.

5) State of warning and alarm

• The state of alarm of warning can be checked with the command TA (TA/HI: Tell

alarm).

(Refer to “11.1. Identifying Alarm and Warning”. )

12.2. Troubleshooting

Refer to a relevant chapters listed below for details.

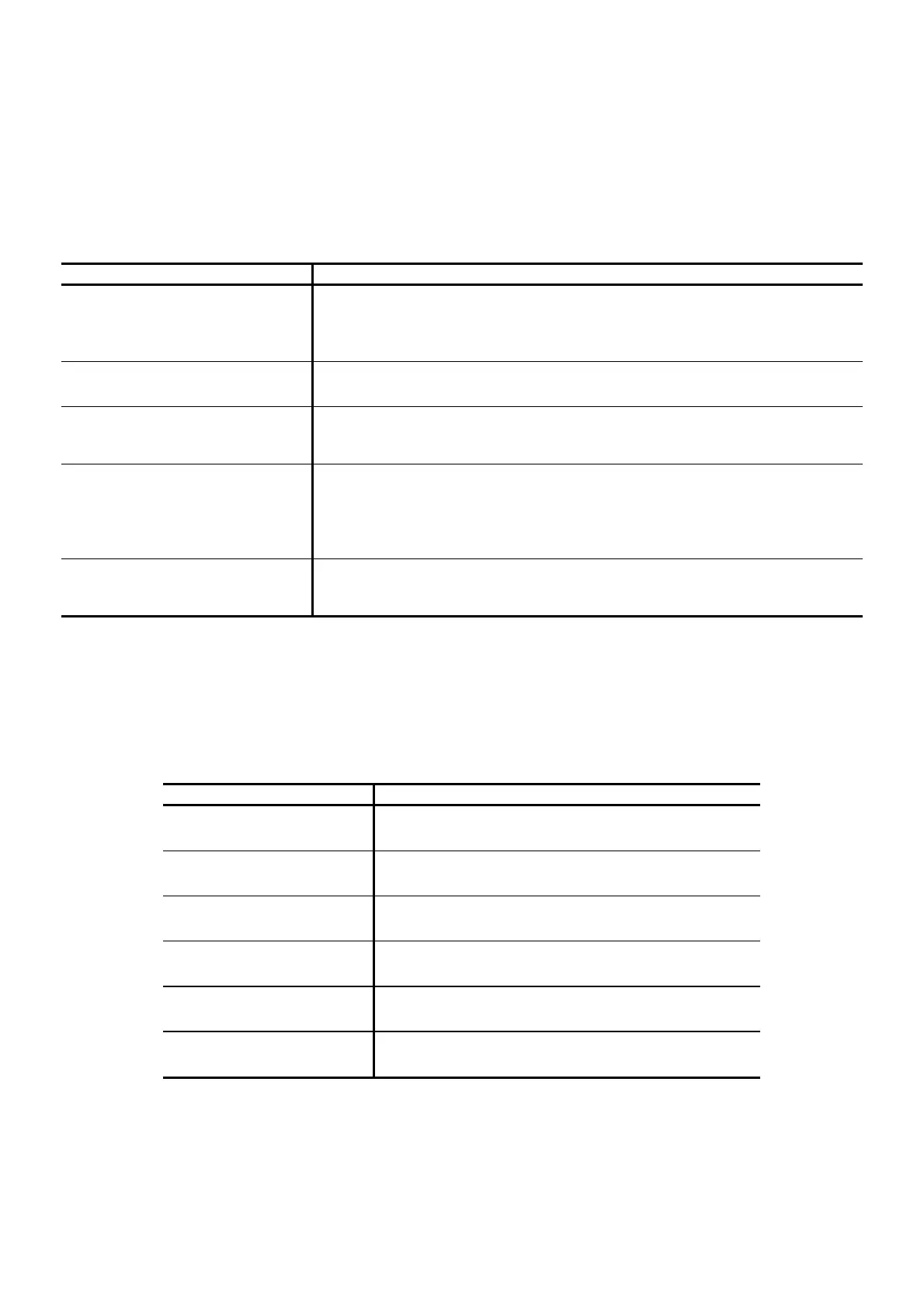

Table 12-2: Failure State

Item Reference

Warning and Alarm

• 11. Warning and Alarm

Power trouble • 12.2.1. Power Trouble

Motor trouble • 12.2.2. Motor Trouble

Vibration, Abnormal noise,

and unstable motion

• 12.2.3. Vibration, Abnormal Noise, and Unstable Settling

Improper positioning • 12.2.4. Improper Positioning

Communication error • 12.2.5. Communication Error

Loading...

Loading...