— 3-7 —

3.3.3. Ground Connection

For grounding the Driver Unit, use braided copper cable or heavy gage cable as possible such as

AWG12 or larger.

The ground terminal is M4 screw. There is a possibility that the thread of a screw is damaged

when the tightening torque of the screw exceeds maximum value 1.2N・m.

!

Caution : Ground the Motor separately when it is isolated from the machine into

which it is installed.

!

Warning : All the ground lines must be connected at one point and the grounding

resistance shall be 100

Ω

or less.

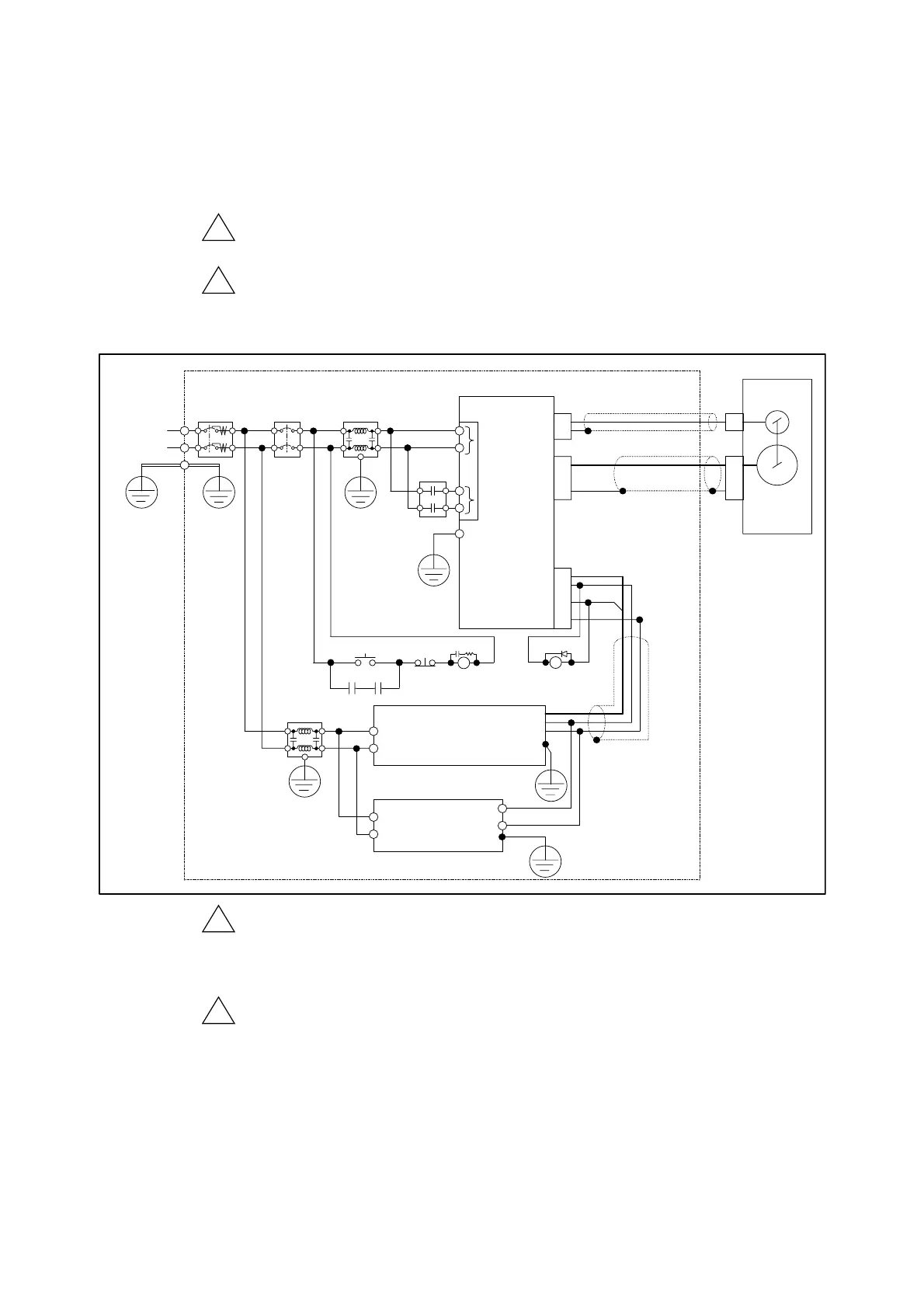

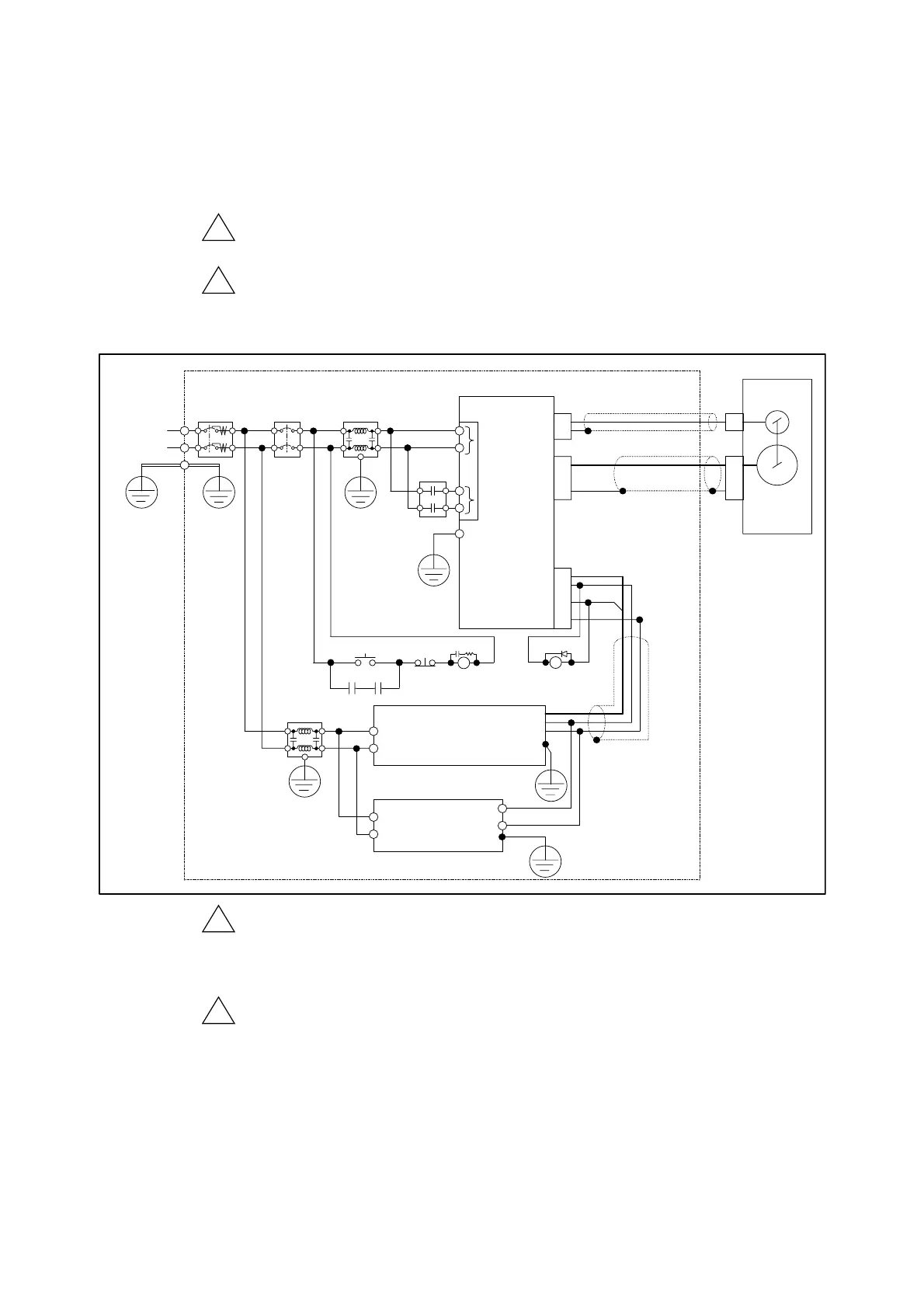

Fig 3-7: Wiring example of power supply

∗1

∗1

∗1:

Connect at one point.

∗1

1

Resolver

Motor

Driver Unit

AC power

Ground earth

Class D

or better

FG

Main power

CN5

Control power

Master controller

• Controller (pulse train output)

• Sequencer

24 VDC

power supply

CN4

CN2

CN3

1

∗1

ELB1

MC1

npu

s

gna

+ 24

DRD

COM

RY1

NF1

+ 24

GND

ELB1: Short circuit breaker

CB1: No fuse breaker

NF1: Noise filter

MC1: Magnetic switch

RY1: Relay

SW1: Main power switch ON

SW2* Main switch OFF

NF

SW1 SW2

MC1

MC1RY1

CB1

!

Caution : We recommend the noise filter below for compliance with the EMC

Directive.

◊ FN2070-10/06 (Schaffner EMC Ltd.) or equivalent.

(Use a breaker compatible with the European Safety Directives.)

!

Caution : Provide a circuit to shut down the main power by the output of an

alarm.

◊ When an alarm occurs, the output DRDY (Driver Unit ready) of the

connector CN2 opens.

The Driver Unit gives the warning P5 (Main AC line low voltage) when the main power is

turned off while the servo is on. [For the main power ON/OFF, refer to “7.1.1. Servo on:

SVON.”]

◊ Input of ACLR (Alarm clear) signal, the command CL (Alarm clear), or turning on the

control power again will clear the alarm.

Loading...

Loading...