Drive Configuration D2 Series Servo Drive User Manual

5-58 HIWIN MIKROSYSTEM CORP.

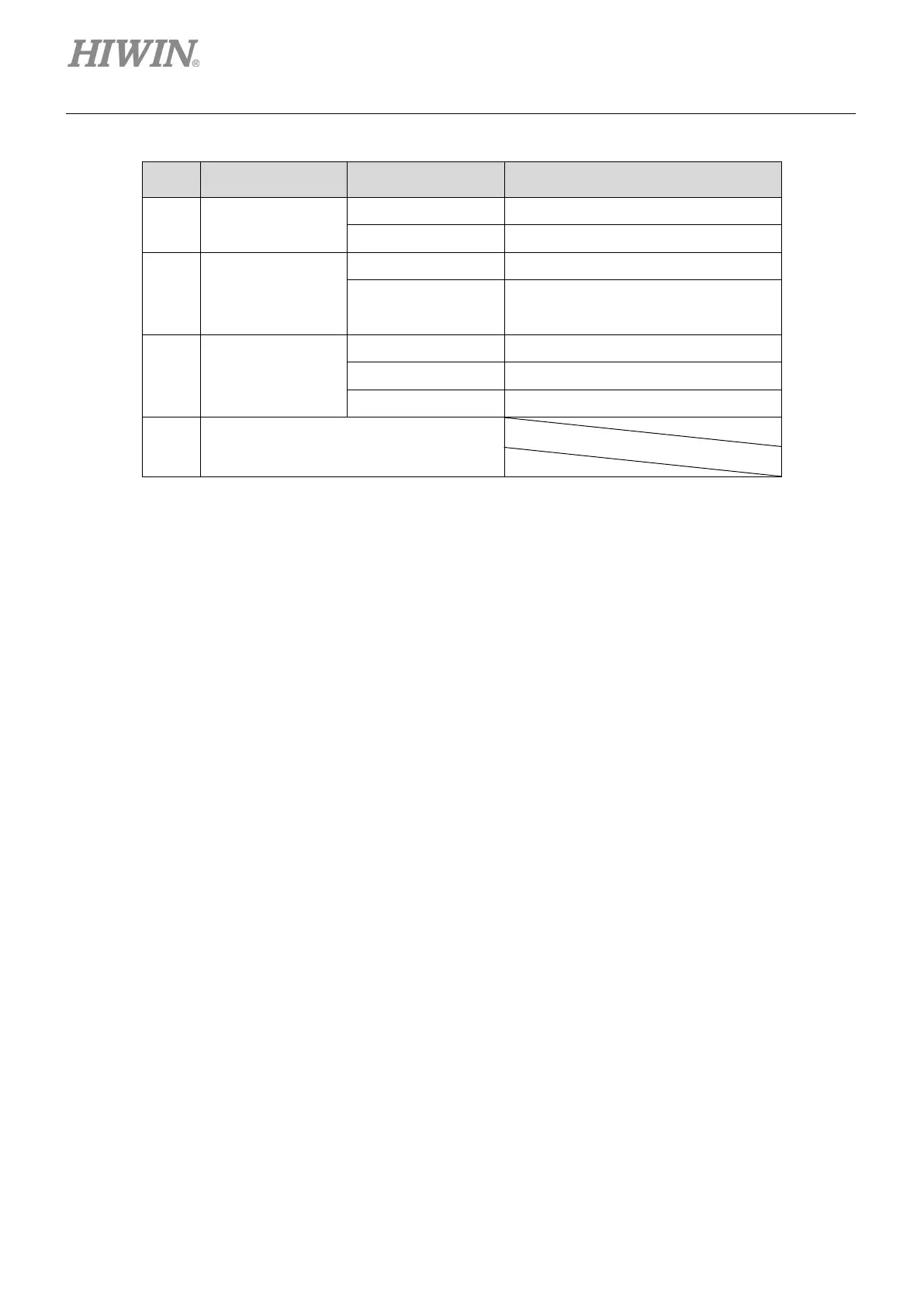

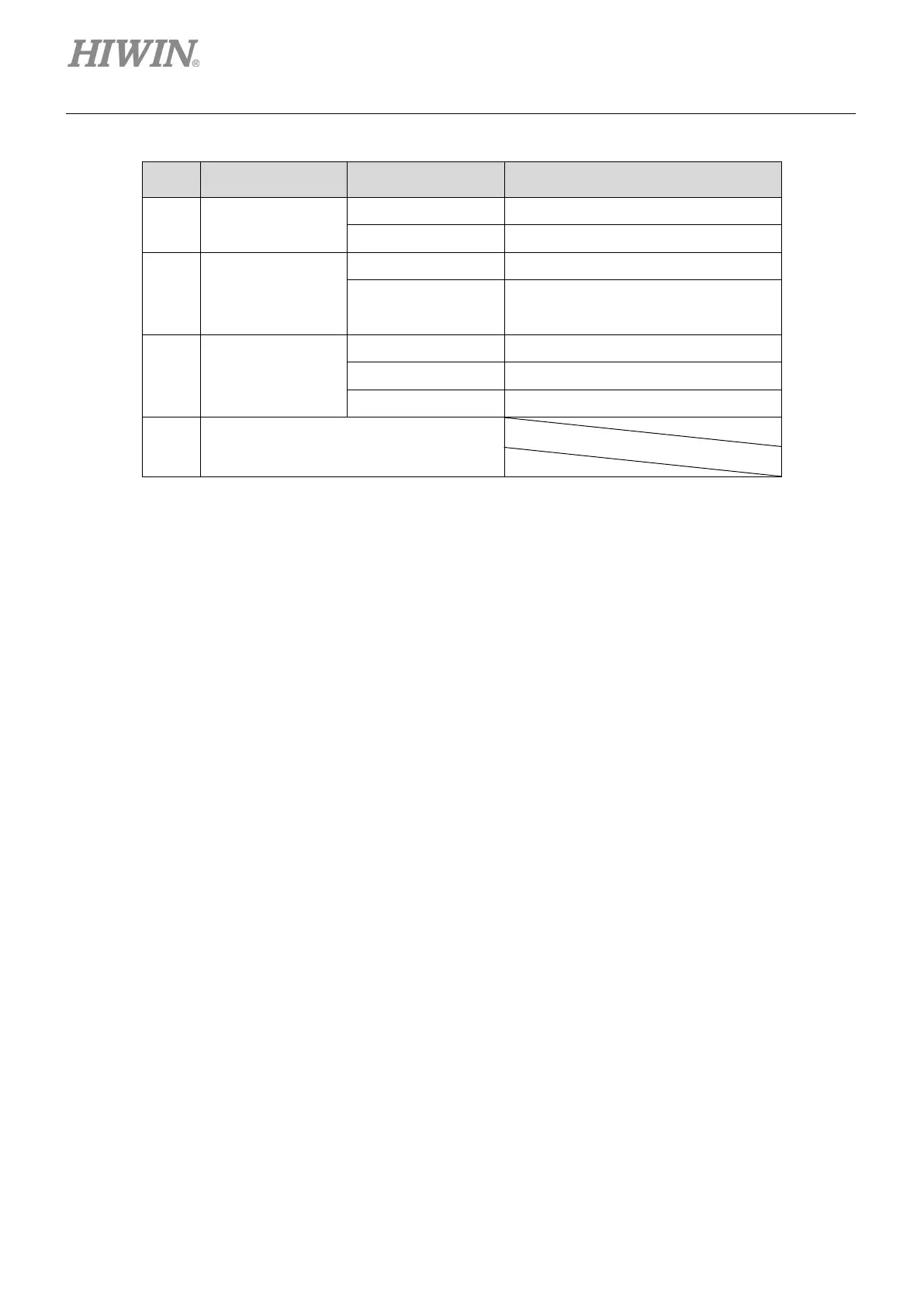

Table5.7.1.1

No. Parameter Option Description

○1

Initial movement

direction

Search first in the left direction.

Search first in the right direction.

○2

Left side condition

Not use the left side condition.

Search the left end stop.

Search the left limit switch.

○3

Right side

condition

Not use the right side condition.

Search the right end stop.

Search the right limit switch.

○4

Current for searching End Stop

○5

Time for searching End Stop

Select one of following items for the left or right side condition.

(1) None: Non-search;

(2) End Stop: Search the end stop;

(3) Limit Switch: Search the limit switch.

Searching end stop should be carried out with parameters ○

4 and ○5 . Parameter ○4 is used to set the

force for searching end stop, and parameter ○

5 is used to set the duration of this force. If this time is

too short, the drive may make a misjudgment of searching end stop before it is found. If this time is

too long, the force on the end stop will increase, or the error of “Soft-thermal threshold reached” will

occur. The current for searching end stop can be set by following steps.

Step 1: Open the “Scope” window, as shown in figure 5.7.4, to set to observe the physical quantity

of “Actual Current”.

Step 2: Use the “Slower Speed” setting to move in the entire stroke.

Step 3: Observe the change of “Actual Current”, and record the maximum value. As shown in

figure 5.7.4, the maximum value of “Actual Current” is about 0.2 A. Therefore, “Search end

stop current” could be set to be slightly more than 0.2 A. For example, it can be set to 0.23

A in this case.

To avoid the error of “Position error too big” occurring at searching the end stop, the slower speed

and time for searching the end stop should meet the following condition:

“Slower Speed” x “Time” < “maximum pos error”.

Loading...

Loading...