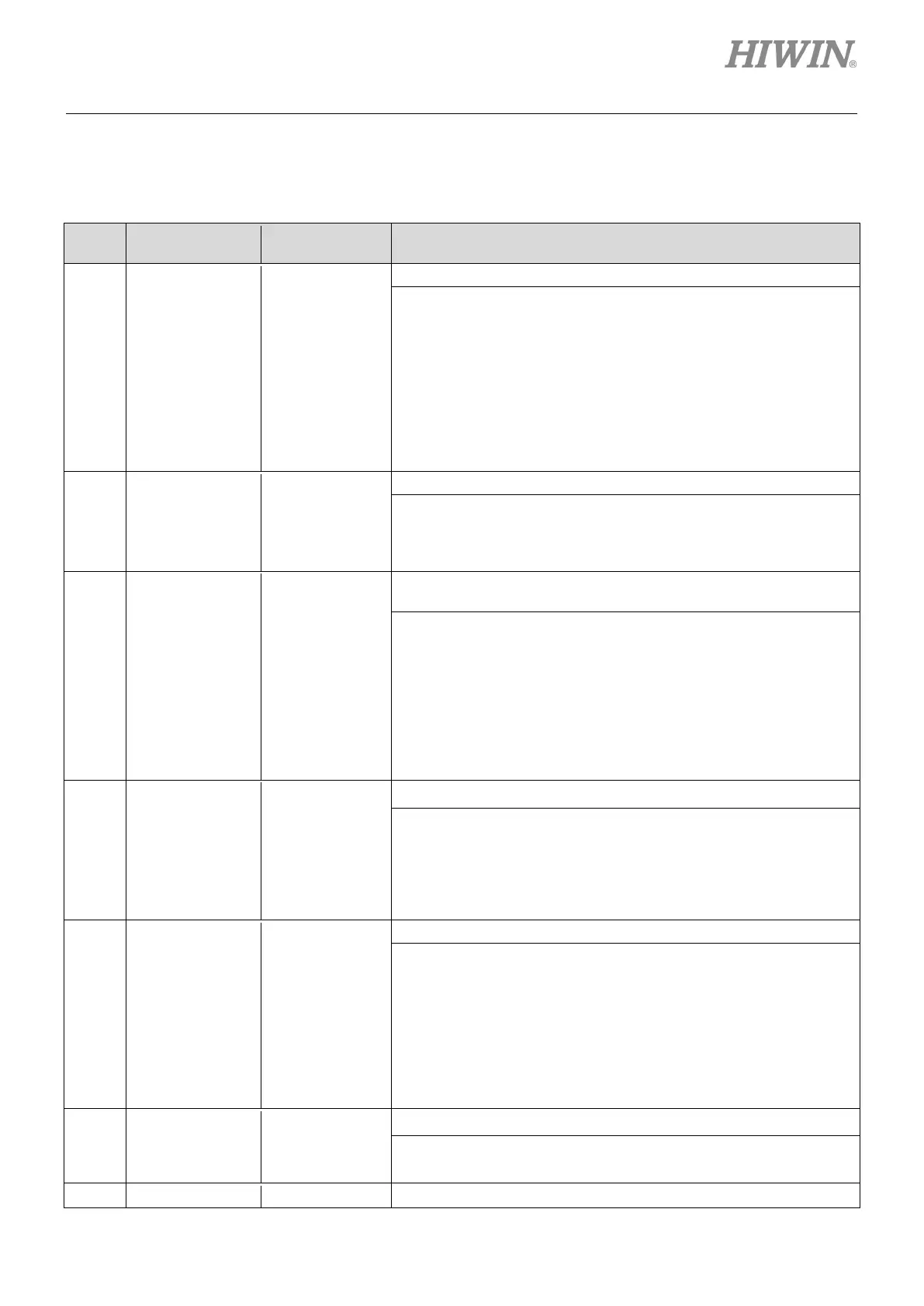

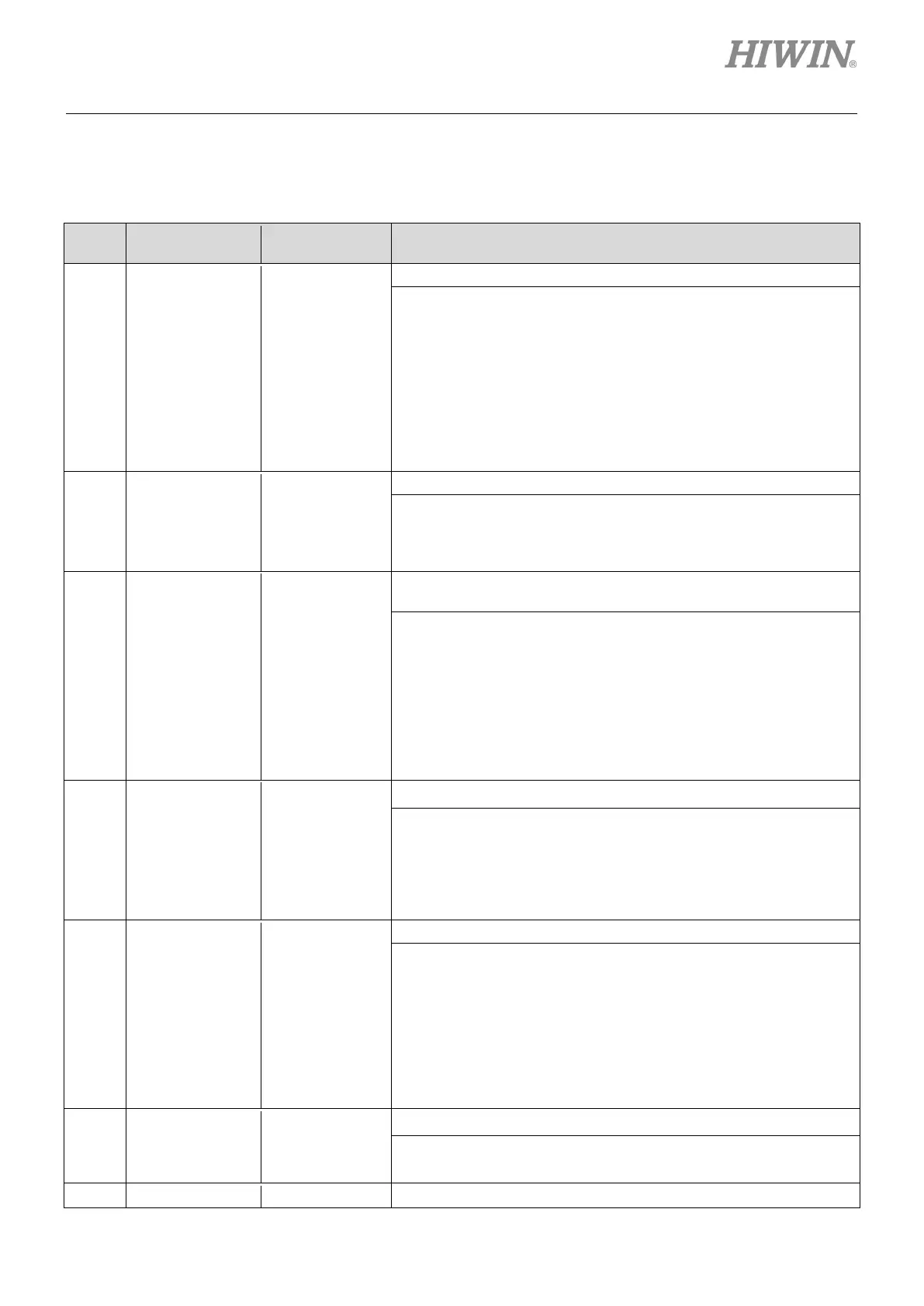

D2 Series Servo Drive User Manual Troubleshooting

HIWIN MIKROSYSTEM CORP. 9-7

9.3 Error codes and troubleshooting

Table9.3.1

No. Error

Description Troubleshooting

1

Motor short (over

current) detected

E01 SHORT

or

ERR E01

The short of three motor phases is detected.

(1) After power-off, unplug the UVW-phase connector at the

drive-

side and measure the resistance between each phase of

UVW and ground to check if there is a short circuit. The short

circuit may burn the motor.

(2) Measure the line-to-line resistance between motor UVW

phases to check that they are close to the specification. If the

line-to-

line resistance is lower than the specification too much,

the motor may be burned.

(3) Separate the motor from the motor power cable, and use a

multimeter to check if the motor power cable is short.

2

Over voltage

detected

E02 OVERV

or

ERR E02

The DC bus voltage in the drive exceeds the limit.

When the motor has a heavy load and is operated at high speed,

the back EMF exceeding the voltage limit will cause this error.

Check if the regenerative resistor needs to be installed, which is

selected according to the load and the motion specification.

3

Position error too

big

E03 PEBIG

or

ERR E03

The position error is greater than “maximum pos error” set in the

“Motion Protection” area.

(1) Check if the gain tuning is improper.

(2) Confirm that the maximum position error is set properly

(“Application center” -> “Protection” -> “maximum pos error”).

(3) Check if the motor movement is obstructed.

(4) Check if the load is too heavy.

(5) Check if the guideway is without maintenance for a long time.

(6) Check if the cable tray is installed too tight.

(7) “W05 SVBIG” continues occurring before “E03”. Use 220 V

4

Encoder error

E04 ENCOD

or

ERR E04

The encoder signal is incorrect or the alarm pin reports an error.

(1) Confirm that all encoder connectors are connected firmly.

(2) Confirm that the encoder wiring is correct.

(3) If the encoder is a digital type, it may be caused by the

external interference. Confirm that the encoder cable has an

anti-interference twisted wire and shield, or is equipped with

5

Soft-thermal

threshold reached

E05 SWHOT

or

ERR E05

Motor overload. (The software detects the motor over-temperature.)

(1) Confirm that the continuous current and peak current during

motor movement comply with the motor specification.

(2) Check if the motor movement is obstructed.

(3) It can be eliminated by resetting and re-enabling the drive.

However, if the current exceeds the motor specification due to

the load and motor parameters, it may occur again.

(4) Reduce the speed, acceleration, and deceleration.

(5) Check if the motor model name or motor current parameter is

6

Motor maybe

disconnected

E06 UVWCN

or

ERR E06

The motor power cable is not physically connected to the drive.

(1) Check if the connector of UVW cable is loose.

(2) Check if the motor model name is set incorrectly.

The drive is over temperature.

Loading...

Loading...