Appendix A: Installation and Setup

Linx 4900 Operating Manual 160 MP65492–1

A.5 Setting up Line Speed

Detection

Linx recommends that you use shaft encoders on production lines where

variable speed is likely. A shaft encoder generates a pulse for a fixed

distance of product movement. This enables the printer to print at a

constant width as the line speed increases or decreases.

If you need to fit a shaft encoder, you should attach it to a suitable

production line drive shaft. It must be installed and driven in a position

where it best follows the movement of the product being printed on.

Linx offers the following range of shaft encoders for line speed detection:

• 2500 pulses per revolution (p.p.r.)

• 5000 pulses per revolution (p.p.r.)

• 10000 pulses per revolution (p.p.r.)

Each shaft encoder is available with a 5-metre cable and a suitable

connector.

For applications where the shaft encoder needs to be driven from a

conveyor belt or from the product, Linx provides the following selection of

encoder wheels:

• 500 mm circumference

• 333 mm circumference

• 304.8 mm (1 ft) circumference

• 200 mm circumference

• 50 mm circumference

A given encoder and encoder wheel has a fixed encoder pitch, that is, the

distance travelled by the product for each pulse cycle of the encoder

output.

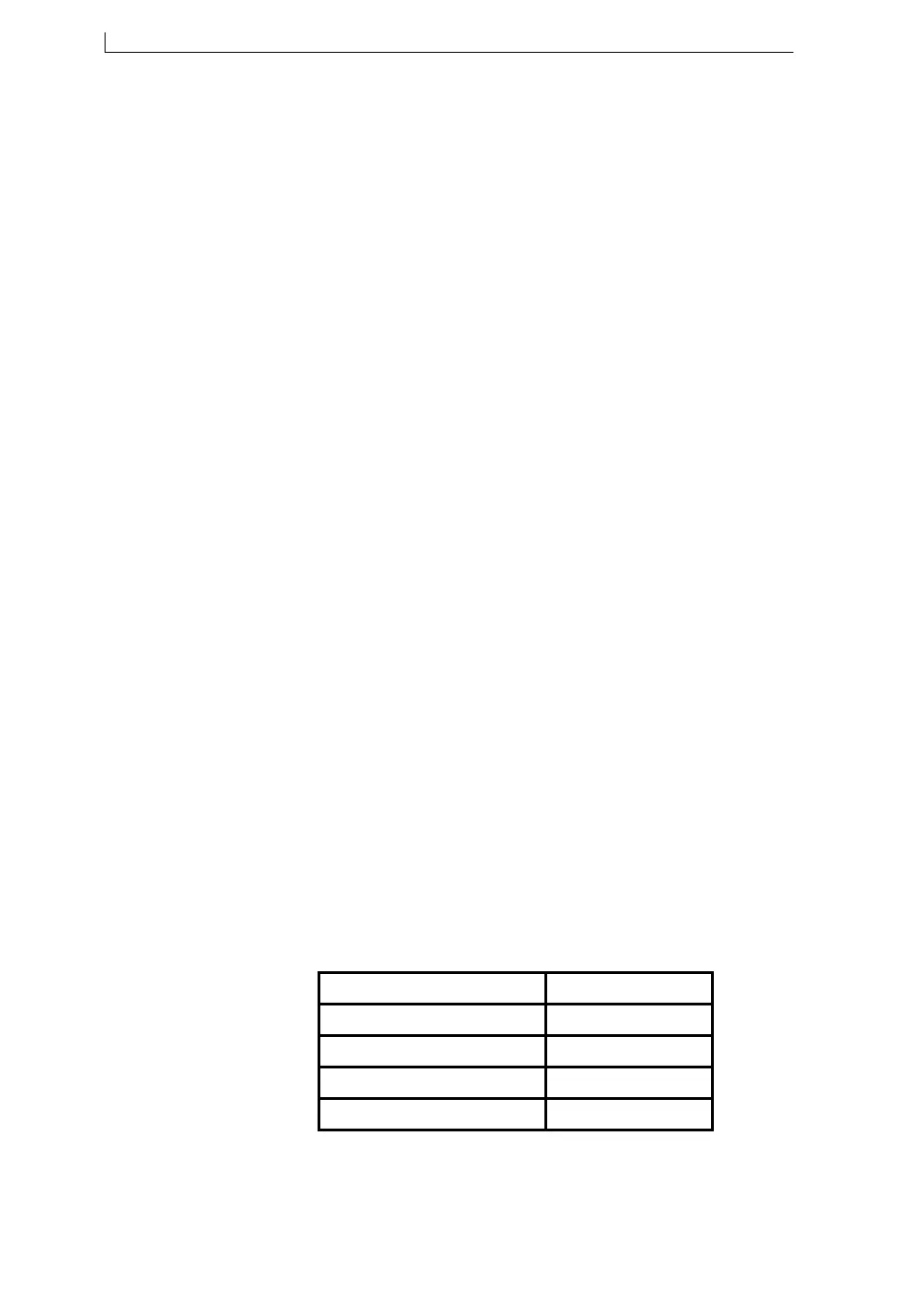

A.5.1 To Connect a Shaft Encoder

You must connect the shaft encoder to the system using a 9-pin D-type

connector. The following table describes the function of each pin:

Figure A-5 Shaft Encoder Pin Connection

68443

Function Connection

+ 24 V Pin 1

0 V Pin 2

+ 5 V Pin 3

Single Ended Input Pin 8

4900 Op Manual.book Page 160 Tuesday, September 9, 2003 12:32 PM

Loading...

Loading...