12.9.2 Selecting the Reference and Feedback

Before using PID control function make sure [E1.00]…[E1.04] ≠ '41: PID deacti-

vation'.

Take the following steps to configure the PID reference:

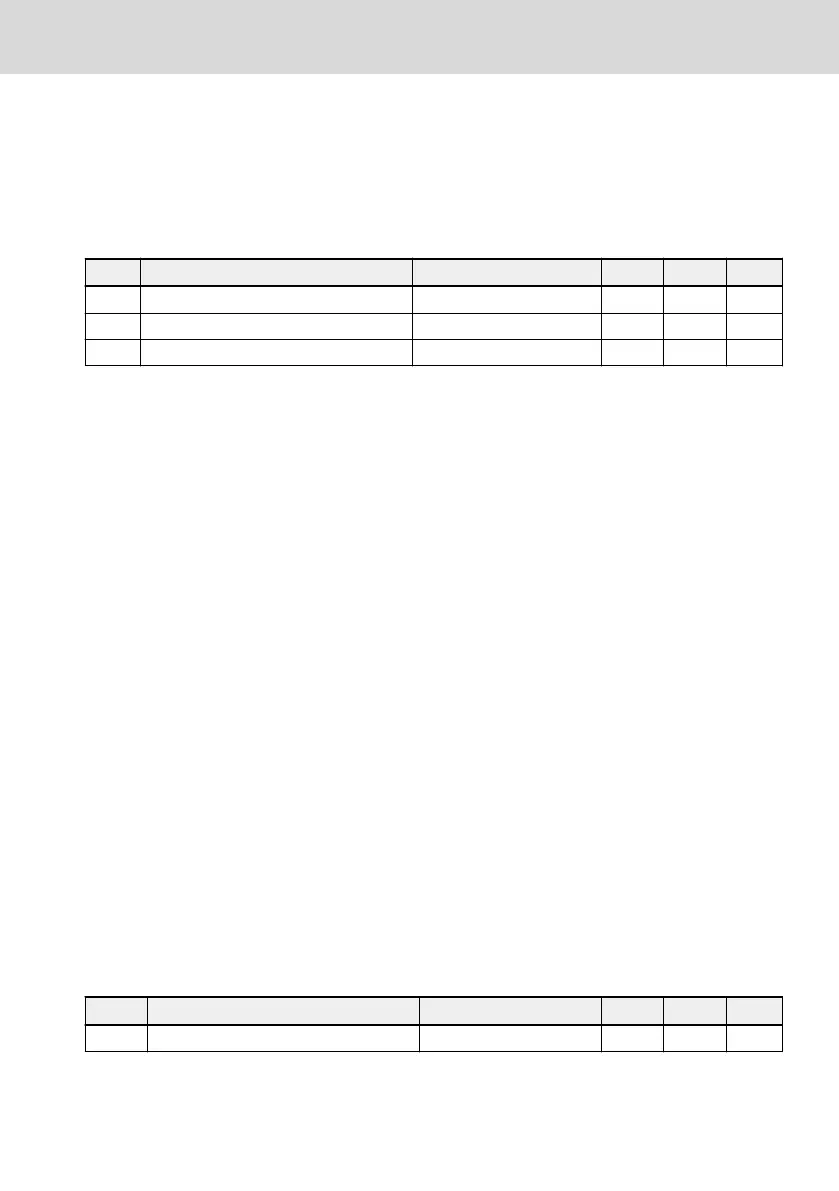

Step 1: Select the PID reference channel

Code Name Setting range Default Min. Attri.

E4.00 PID reference channel 0...9 0 – Stop

E4.03 PID engineering analog reference 0.00...10.00 0.00 0.01 Run

E4.04 PID engineering speed reference 0...30,000 rpm 0 1 Run

● [E4.00] = 0: Inactive

The PID control function is inactive.

● [E4.00] = 1: Panel potentiometer

The reference value is set by adjusting the potentiometer on the operating

panel.

● [E4.00] = 2: Panel button

The reference value is set by E0.07 'Digital setting frequency', which can be

decreased or increased by pressing the <▼> or <▲> buttons on the operating

panel respectively when the frequency converter is running.

● [E4.00] = 3: AI1 analog input

The reference value is set by AI1 analog input.

● [E4.00] = 4: AI2 analog input

The reference value is set by AI2 analog input.

● [E4.00] = 5: X5 pulse input

The reference value is set by pulse signal via X5 input.

● [E4.00] = 7: Communication

The reference value is set by engineering software, PLC or other external devi-

ces via Modbus or other communication.

● [E4.00] = 8: Analog reference E4.03

The reference value is set by parameter E4.03.

● [E4.00] = 9: Speed reference E4.04

The reference value is set by parameter E4.04.

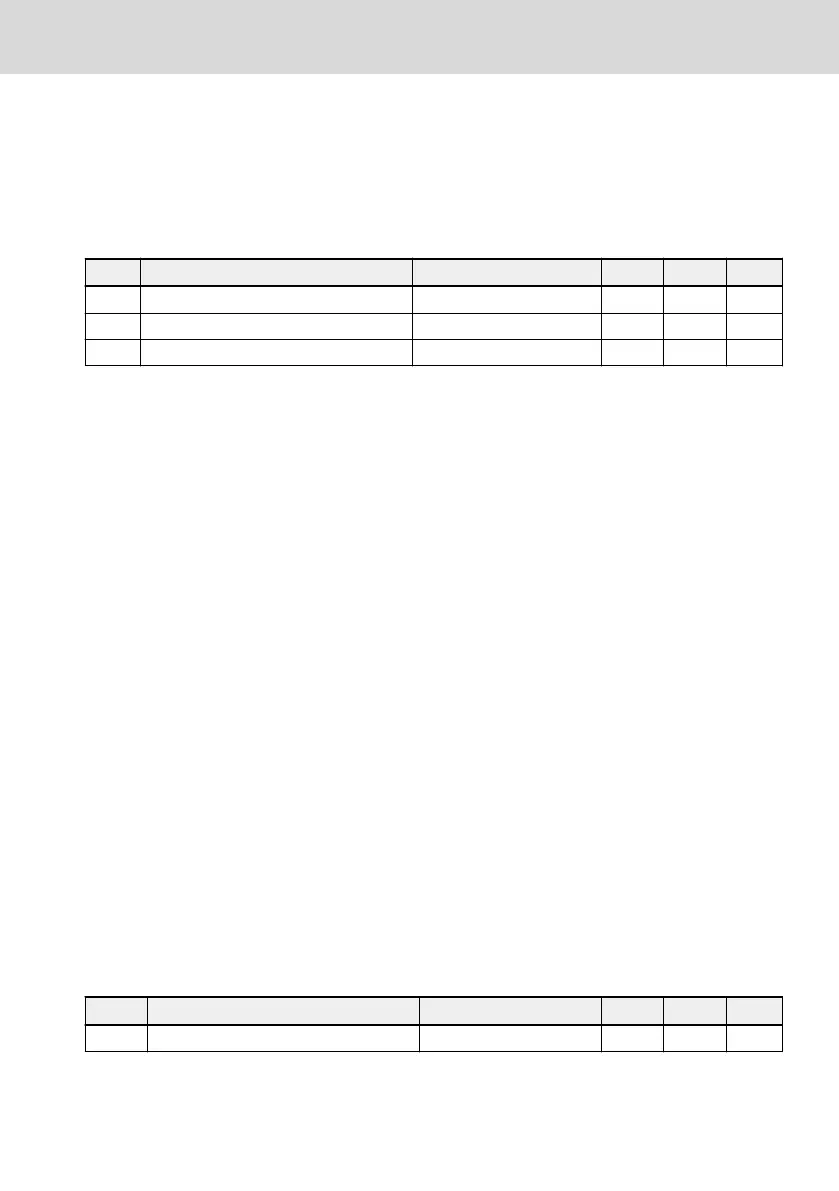

Step 2: Select the PID feedback channel

Code

Name Setting range Default Min. Attri.

E4.01 PID feedback channel 0...99 0 – Stop

● 0: AI1 analog input

Feedback value is set by AI1 analog input.

EFC x610 Series

Bosch Rexroth AG

Functions and Parameters

DOK-RCON03-EFC-X610***-IT05-EN-P

187/389

Loading...

Loading...