Motor thermal protection without temperature sensor

This function is to realize the motor thermal protection based on the thermal

model of motor.

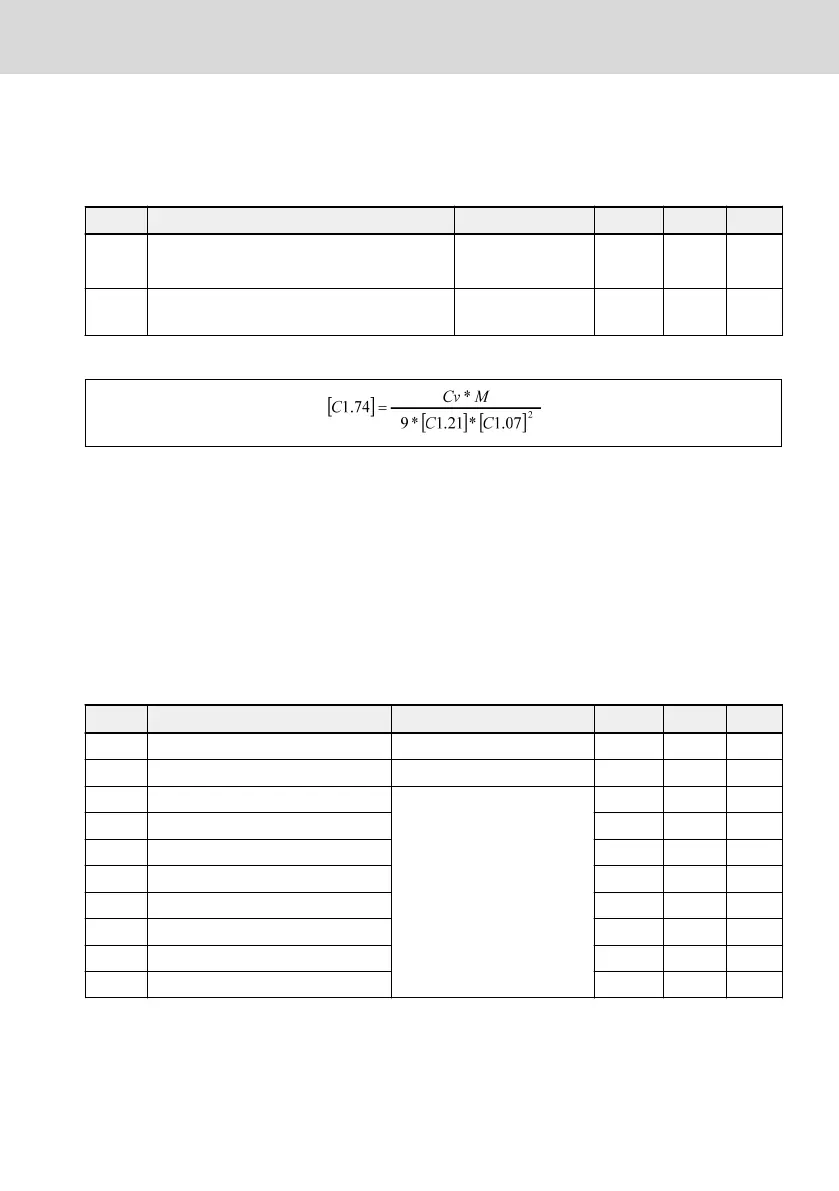

Code Name Setting range Default Min. Attri.

C1.69 Motor thermal model protection setting

0: Inactive

1: Active

1 – Stop

C1.74

Motor thermal model protection time con-

stant

0.0...400.0 min DOM 0.1 Stop

[C1.74] is obtained by the equation below:

Cv: Specific heat capacity

(J/kg)

Cv of iron (Fe): 450 J/kg

Cv of aluminum (Al): 900 J/kg

M: Motor weight (kg)

Fig. 12-55: Motor thermal protection time constant

Increase the value of C1.74 'Motor thermal model protection time constant' ap-

propriately if motor overload protection error code 'OL-2' occurs frequently. This

function can be disabled by setting [C1.69] = 0, if necessary.

Ensure that the converter output current does not exceed 110 % of the [C1.07]

'Motor rated current'.

Motor overload pre-warning

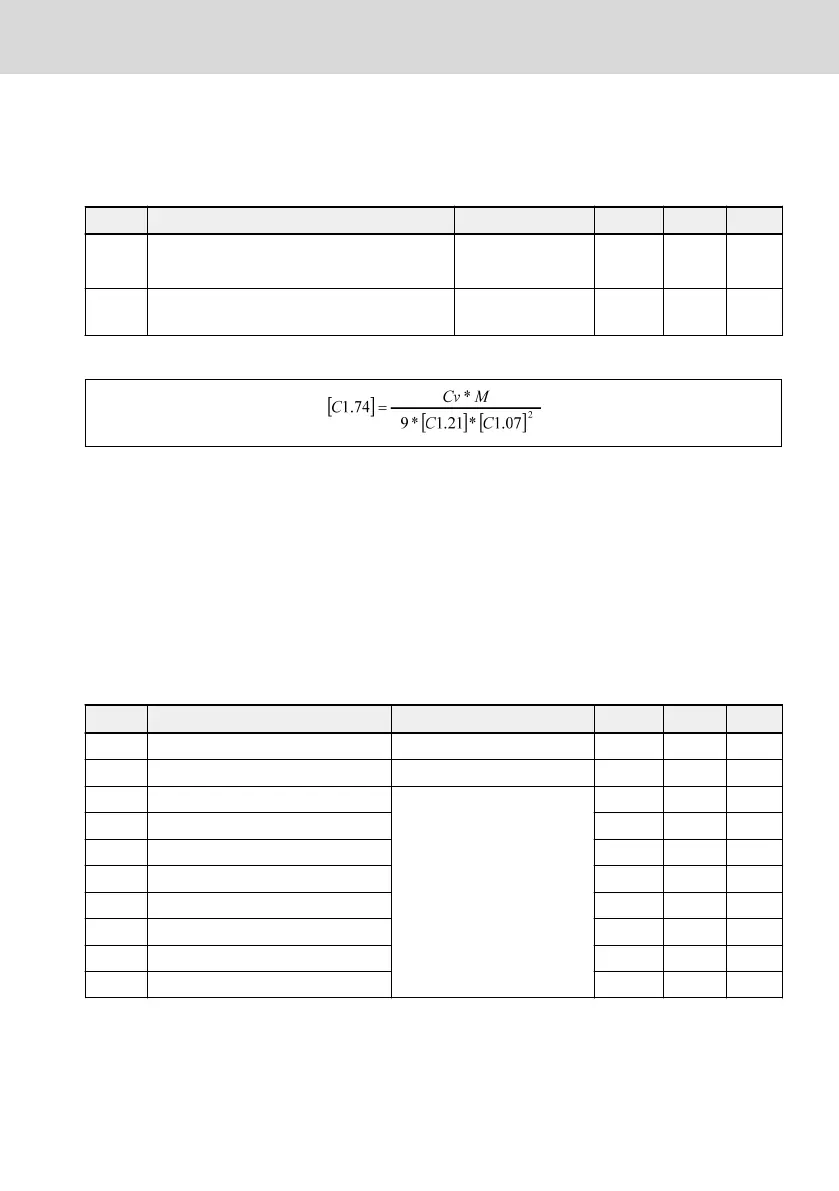

Code

Name Setting range Default Min. Attri.

C1.70 Motor overload pre-warning level 100.0...250.0 % 100.0 0.1 Run

C1.71 Motor overload pre-warning delay 0.0...20.0 2.0 0.1 Run

E2.01 DO1 output setting

12: Motor overload pre-

warning

1 – Stop

E2.15 Relay 1 output selection 1 – Stop

H8.20 EDO output setting 1 – Stop

H8.21 Extended relay output selection 1 – Stop

H9.00 Extended relay 1 output selection 0 – Stop

H9.01 Extended relay 2 output selection 0 – Stop

H9.02 Extended relay 3 output selection 0 – Stop

H9.03 Extended relay 4 output selection 0 – Stop

When the output current exceeds the threshold defined by C1.70 'Motor over-

load pre-warning level' for [C1.71] 'Motor overload pre-warning delay', the pre-

warning signal is active on DO1 or Relay 1 output. Users may use the indication

of this pre-warning signal according to actual application situations. The signal is

immediately deactivated when the output current is lower than the threshold.

EFC x610 Series

Bosch Rexroth AG

Functions and Parameters

DOK-RCON03-EFC-X610***-IT05-EN-P

207/389

Loading...

Loading...