Vista Digital Mixing System

8-6 Vista 8 Differences

SW V3.5 Date printed: 05.04.2005

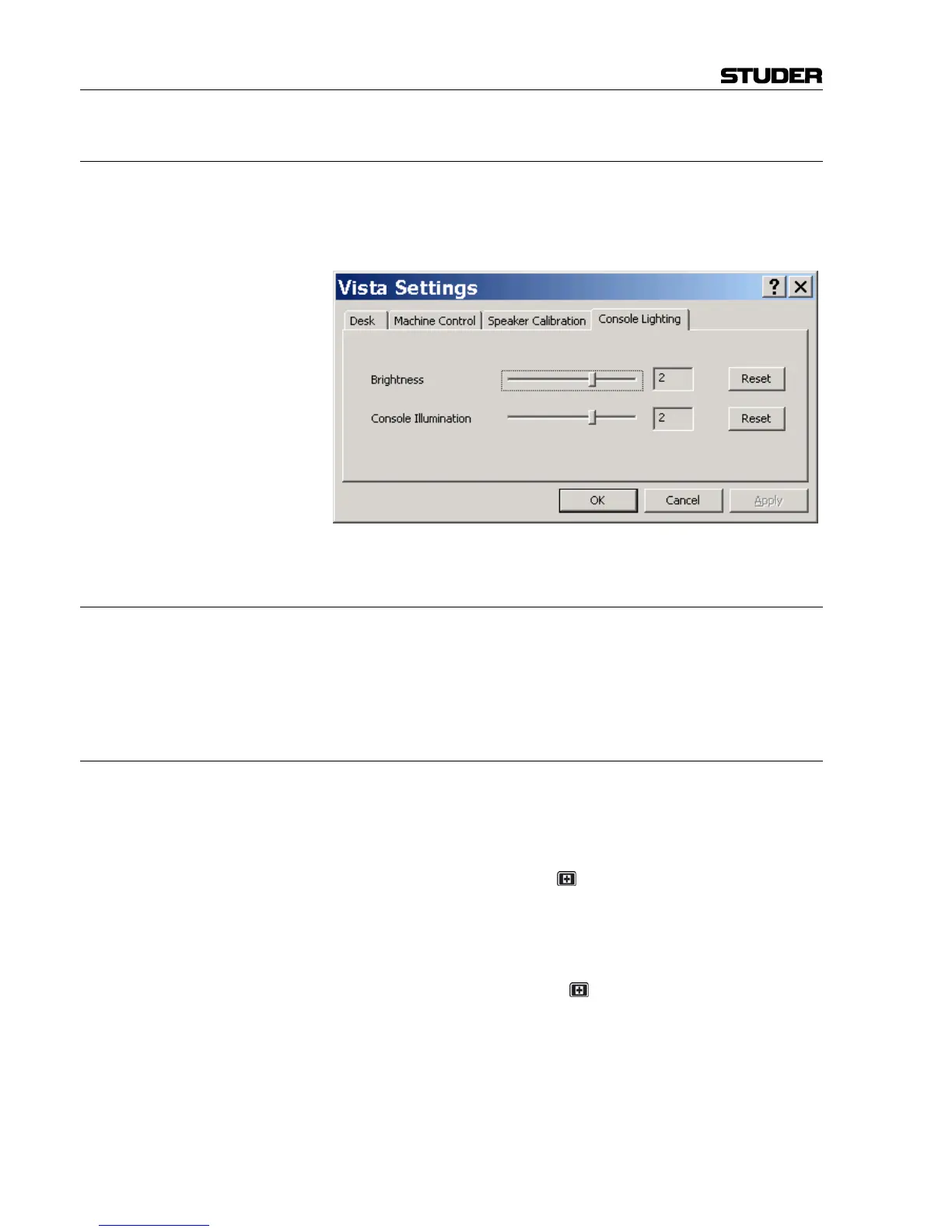

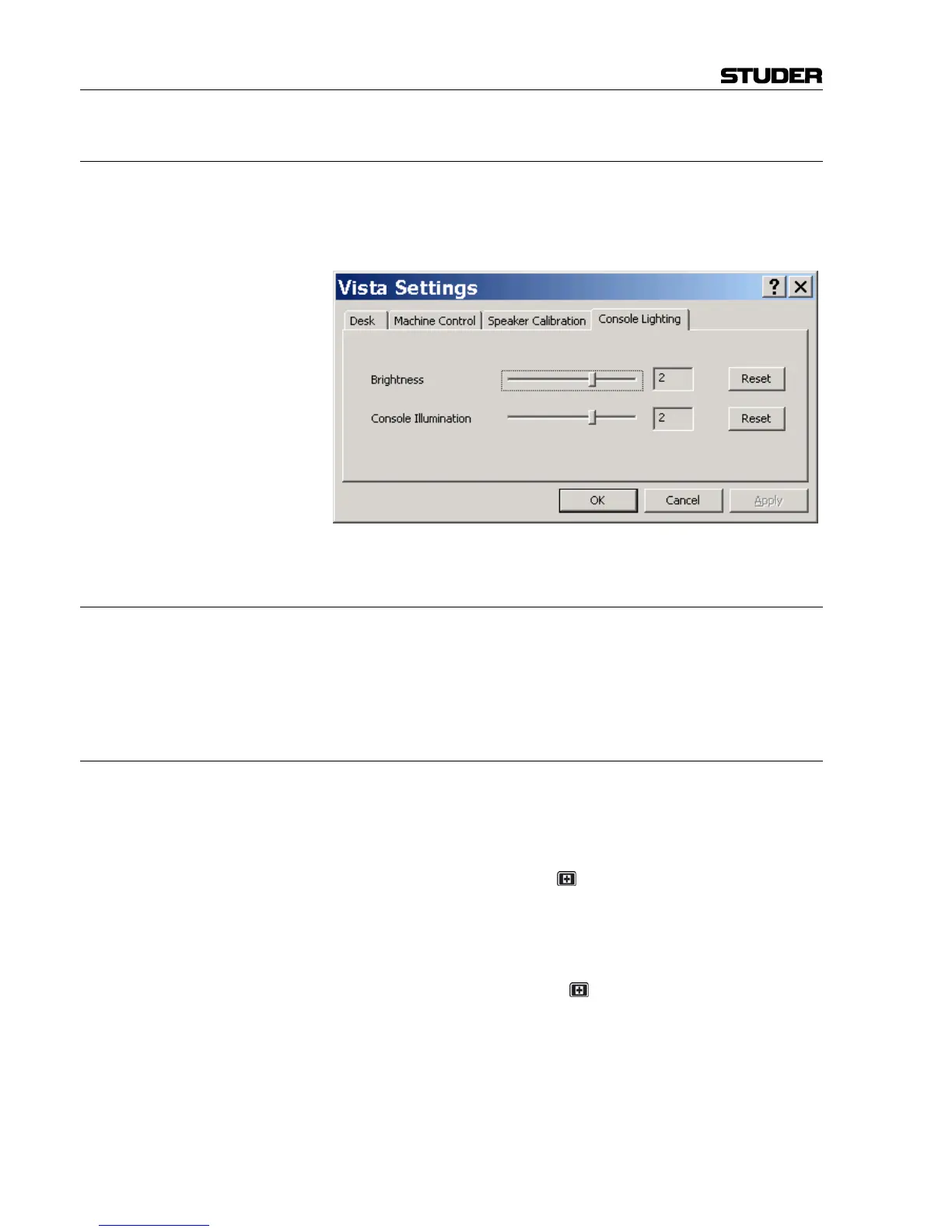

8.2.5 Console Illumination (optional)

Vista 8 may be ordered with optional illumination. It may be varied in in-

tensity using the “Option: Vista Settings” menu. There are two separate

controls for the console lights (including Vistonics

®

backlights) and for the

illumination mounted on top of the meter bridge.

8.2.6 Redundant Control System

If the console is equipped with a redundant control system, the external

graphic controller screen is running at a resolution of 1280 × 1024 pixels

by default. Resolution may be reduced to 1024 × 768 pixels by setting an

internal jumper (see service manual for more details).

8.2.6.1 Switchover to the Redundant Control System (Emergency Switch)

During normal operation, the main control system is backing up all neces-

sary data of the currently loaded project in regular intervals to the redun-

dant control system’s hard drive. The interval is set in the

“D950system.ini” file located within the Windows directory. If for any rea-

son it should be necessary to switch to the redundant control system, the

user may hold the emergency key

for about 3 seconds. This will switch

the whole system over to the second control system. The user will then see

the redundant system on the graphic controller screen and start the console

application by double-clicking on the appropriate icon on the desktop. It

will load the data previously backed up by the healthy main system, and

the operator has full access to the whole system again. While the redundant

system is active, the emergency key

is lit. However, it is not intended to

switch back to the main control system during a live situation. In such a

case, the data can be backed up using a CD-R or a USB memory stick and

put back to the main control system after the production has been finished.

Loading...

Loading...