Startup Procedure and Test Run

4

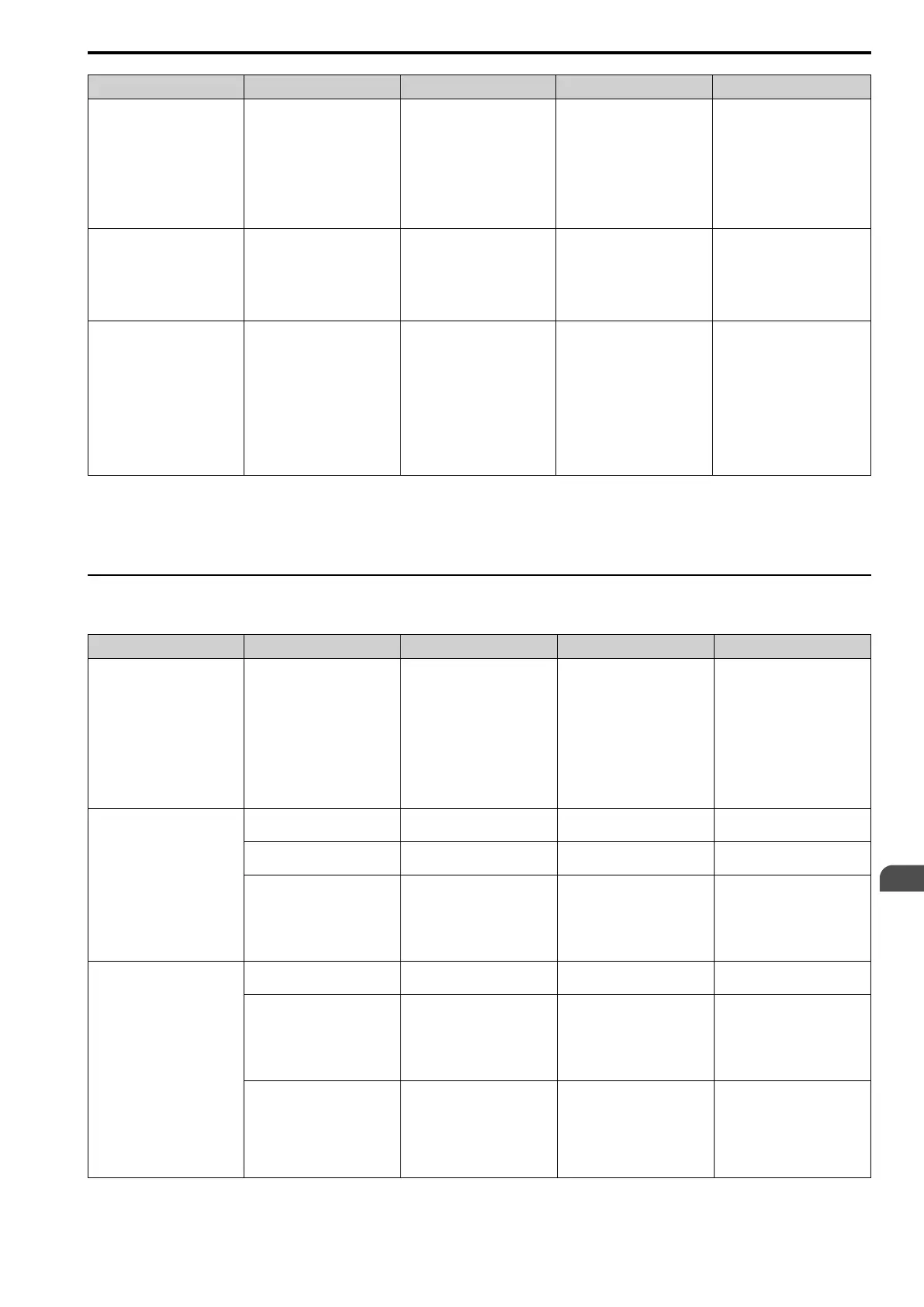

4.10 Fine Tuning during Test Runs (Adjust the Control Function)

YASKAWA SIEPC71061705H GA700 Series Technical Manual 201

Issue Parameter Number Possible Solutions Default Recommended Setting

The drive cannot find speed

response for low speed or high

speed.

• C5-07 [ASR Gain Switchover

Frequency]

*4

• High speed

C5-01 [ASR Proportional Gain

1]

C5-02 [ASR Integral Time 1]

• Low speed

C5-03 [ASR Proportional Gain

2 (P)]

*3

C5-04 [ASR Integral Time 2]

Change the ASR proportional

gain and ASR integral time to

conform to the output frequency.

• C5-07 = 0.0 Hz

• C5-01 = 10.00

• C5-02 = 0.500 s

• C5-03 = 20.00

• C5-04 = 0.500 s

C5-07: 0.0 to maximum output

frequency

Hunting or oscillation C5-06 [ASR Delay Time]

*4

• If torque or speed response are

slow, decrease the setting

value in increments of 0.010.

• If the rigidity of the machine

is unsatisfactory and vibration

is possible, increase the

setting value.

0.004 s 0.004 s to 0.020 s

When you operate the drive at a

frequency close to zero speed, the

motor rotates at a frequency

slightly higher than the frequency

reference.

• E1-09 [Minimum Output

Frequency]

• n4-70 [Speed Command Comp

@ Low Freq]

• Set E1-09 > 0.

Note:

When frequency reference

E1-09 < 0, the drive output

will turn OFF.

• Decrease the setting value of

n4-70 in 0.1 Hz increments.

Note:

If you set the value too low,

the motor can rotate in

reverse.

• E1-09 = 0.0 Hz

• n4-70 = 1.00 Hz

• E1-09 = 0.5 Hz

• n4-70 = 0.50 Hz

*1 The default setting changes when the settings for C6-01 [Normal / Heavy Duty Selection] and o2-04 [Drive Model (KVA) Selection]

change.

*2 The default setting changes when the setting for o2-04 [Drive Model Selection] changes.

*3 Refer to the section on C5-xx parameters for more information about speed control (ASR).

*4 The best values for a no-load operation are different than the best values for actual loading operation.

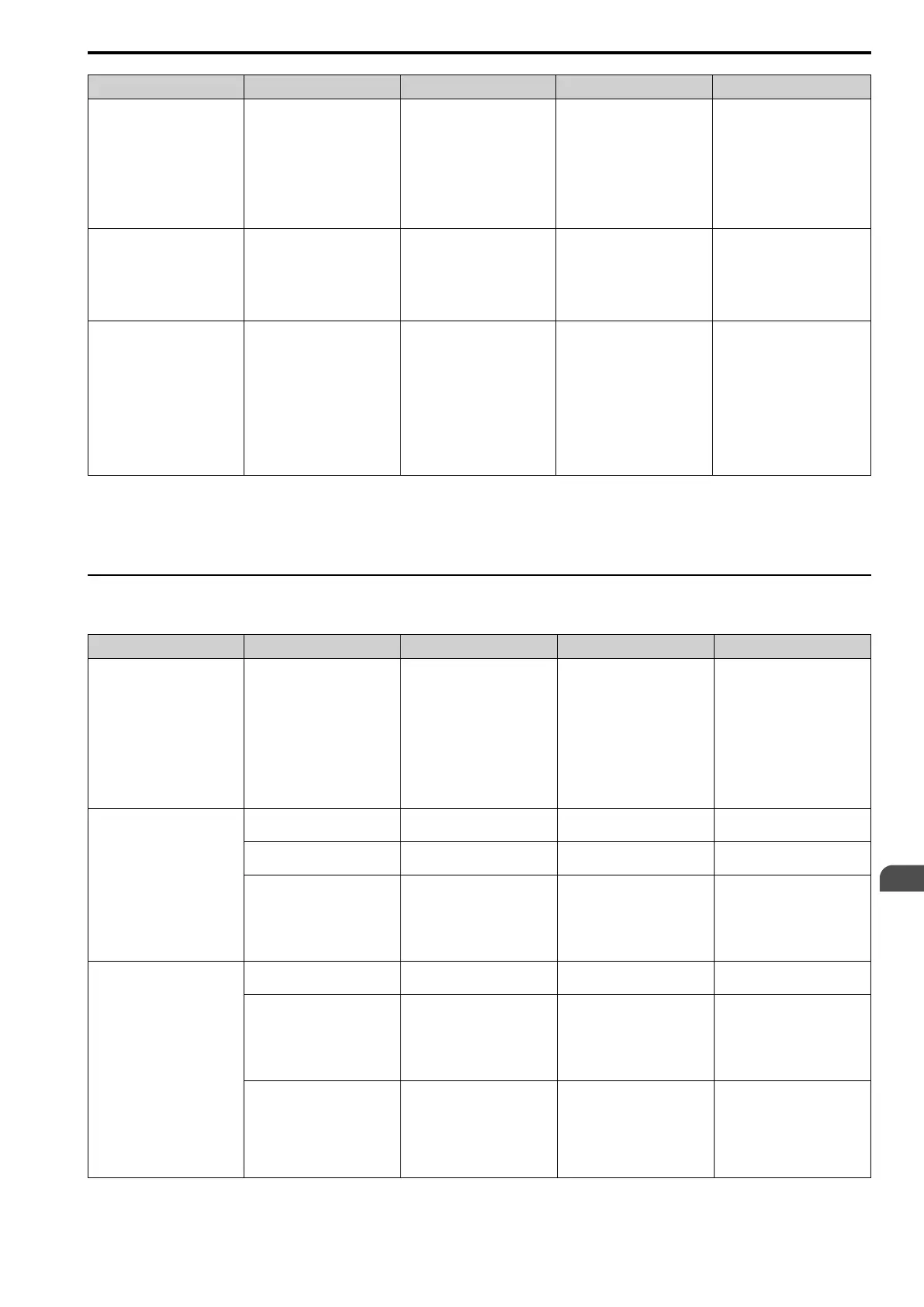

◆ Open Loop Vector Control for PM Motors

Table 4.21 Parameters for Fine Tuning the Drive (A1-02 = 5 [OLV/PM])

Issue Parameter Number Possible Solutions Default Recommended Setting

Unsatisfactory motor

performance

E1-xx parameters, E5-xx

parameters

• Check the settings for E1-06,

E1-04 [Base Frequency,

Maximum Output Frequency].

• Check the E5-xx and make

sure that you set all motor data

correctly.

Note:

Do not set E5-05 [PM Motor

Resistance (ohms/phase)] to a

line-to-line resistance value.

• Do Auto-Tuning.

- -

Unsatisfactory motor torque and

speed response

n8-55 [Motor to Load Inertia

Ratio]

Adjust to align the load inertia

ratio of the motor and machine.

0 Near the load inertia ratio.

n8-45 [Speed Feedback Detection

Gain]

Decrease the setting value in

increments of 0.05.

0.80 -

C4-01 [Torque Compensation

Gain]

Adjust the setting value.

Note:

If you set this value too high,

it can cause

overcompensation and motor

oscillation.

0.00 1.00

• Oscillation when the motor

starts.

• Motor stalls.

n8-51 [Pull-in Current @ Accel/

Decel]

Increase the setting value in

increments of 5%.

50% -

• b2-02 [DC Injection Braking

Current]

• b2-03 [DC Inject Braking

Time at Start]

Use DC Injection Braking at start.

Note:

This can cause the motor to

rotate in reverse for

approximately 1/8 of a turn at

start.

• b2-02: 50%

• b2-03: 0.00 s

• b2-02: Adjust as necessary.

• b2-03: 0.5 s

n8-55 [Motor to Load Inertia

Ratio]

Increase the setting value.

Note:

When you operate a single

motor or with a minimum

quantity of inertia, if you set

this value too high, it can

cause motor oscillation.

0 Near the load inertia ratio.

Loading...

Loading...