10.9 Peripheral Devices and Options

470 YASKAWA SIEPC71061705H GA700 Series Technical Manual

10.9 Peripheral Devices and Options

toTable 10.76 show the available peripheral devices and options for the drive. Contact Yaskawa or your nearest

sales representative to make an order.

• Selection: Refer to the drive catalog for information about available products.

• Installation and wiring: Refer to the instruction manual for each option.

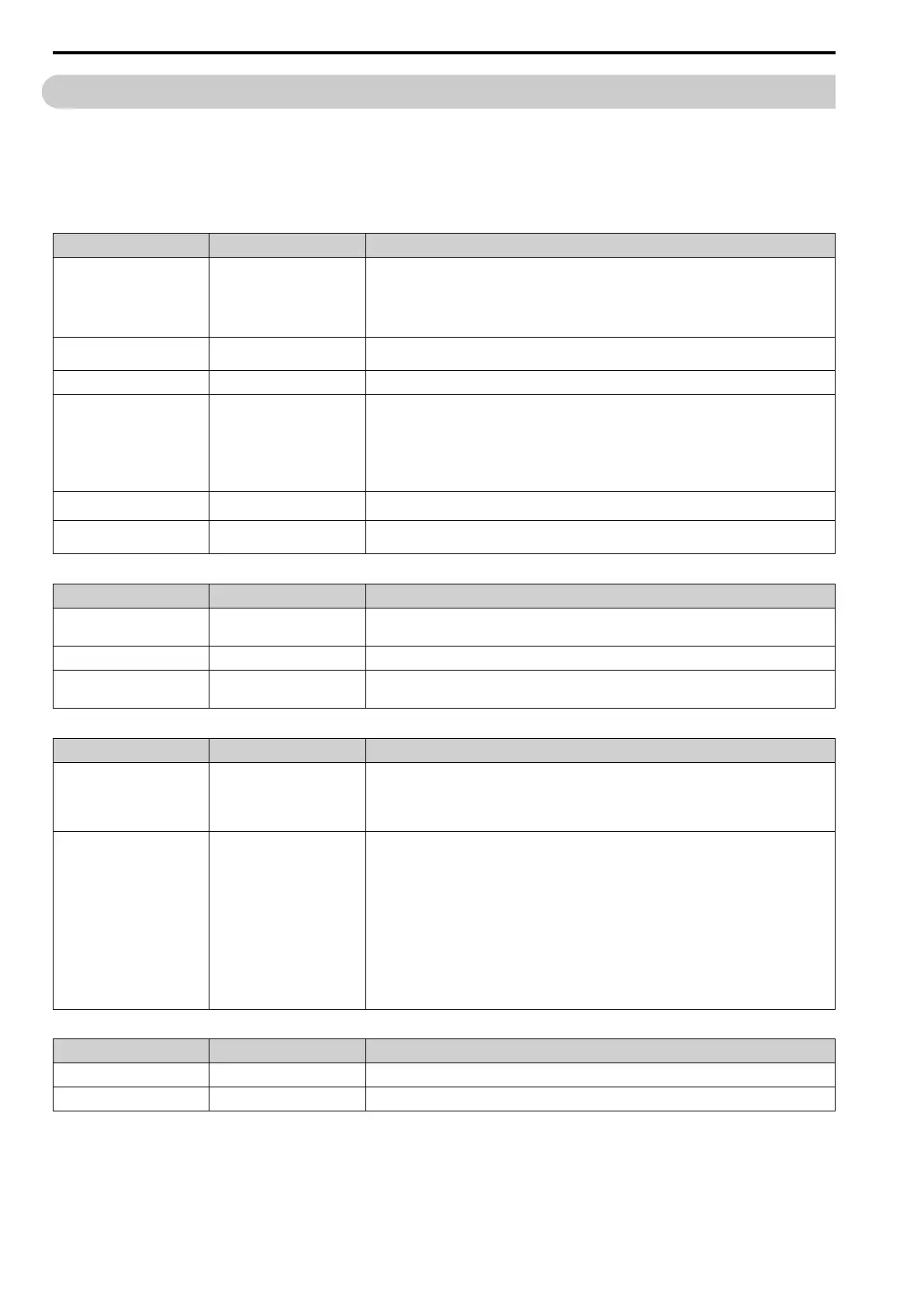

Table 10.72 Main Circuit Options

Name Model Intended Use

AC reactor LR3 series and ALR3 series

To improve the drive input power factor.

• To prevent damage to the drive when the power supply capacity is large. You must only use this option

when the power supply capacity is more than 600 kVA.

• To decrease harmonic current.

• To improve the power supply total power factor.

Braking Resistor ERF-150WJ Series

To decrease the regenerative energy of the motor and decrease the deceleration time (duty cycle of 3%

ED). You must also use the installation attachment.

Braking Unit CDBR series

Use with a braking resistor unit to decrease motor deceleration times.

Residual Current Monitoring/

Detection (RCM/RCD)

NV and NS series

To prevent short circuit damage to the power supply system, provide overload protection for wiring,

prevent electrical shock, and provide ground fault protection against earth leakage fires.

Note:

• You can use a molded-case circuit breaker as a replacement for a RCM/RCD that is upstream in the

power supply system.

• When you use a high frequency RCM/RCD at the power input side of the drive, make sure that each

drive has a minimum cumulative sensitivity amperage of 30 mA.

Molded-Case Circuit Breaker

(MCCB)

NF series

To prevent short circuit damage to the power supply system and provide overload protection for wiring.

Input Side Magnetic Contactor

(MC)

SC series

To prevent burn damage when connecting a braking resistor. This option fully opens the circuit between

the power supply and drive.

Table 10.73 Keypad

Name Model Intended Use

Keypad Remote Cable

1 m: WV001

3 m: WV003

To connect the keypad and drive.

This option is an RJ-45, 8-pin straight-through UTP CAT5e cable.

Installation Support Set A 900-192-933-001

To attach the keypad to the control panel. This option uses screws.

Installation Support Set B 900-192-933-002

To attach the keypad to the control panel. This option uses nut clamps.

Use this option when weld studs are located in the control panel.

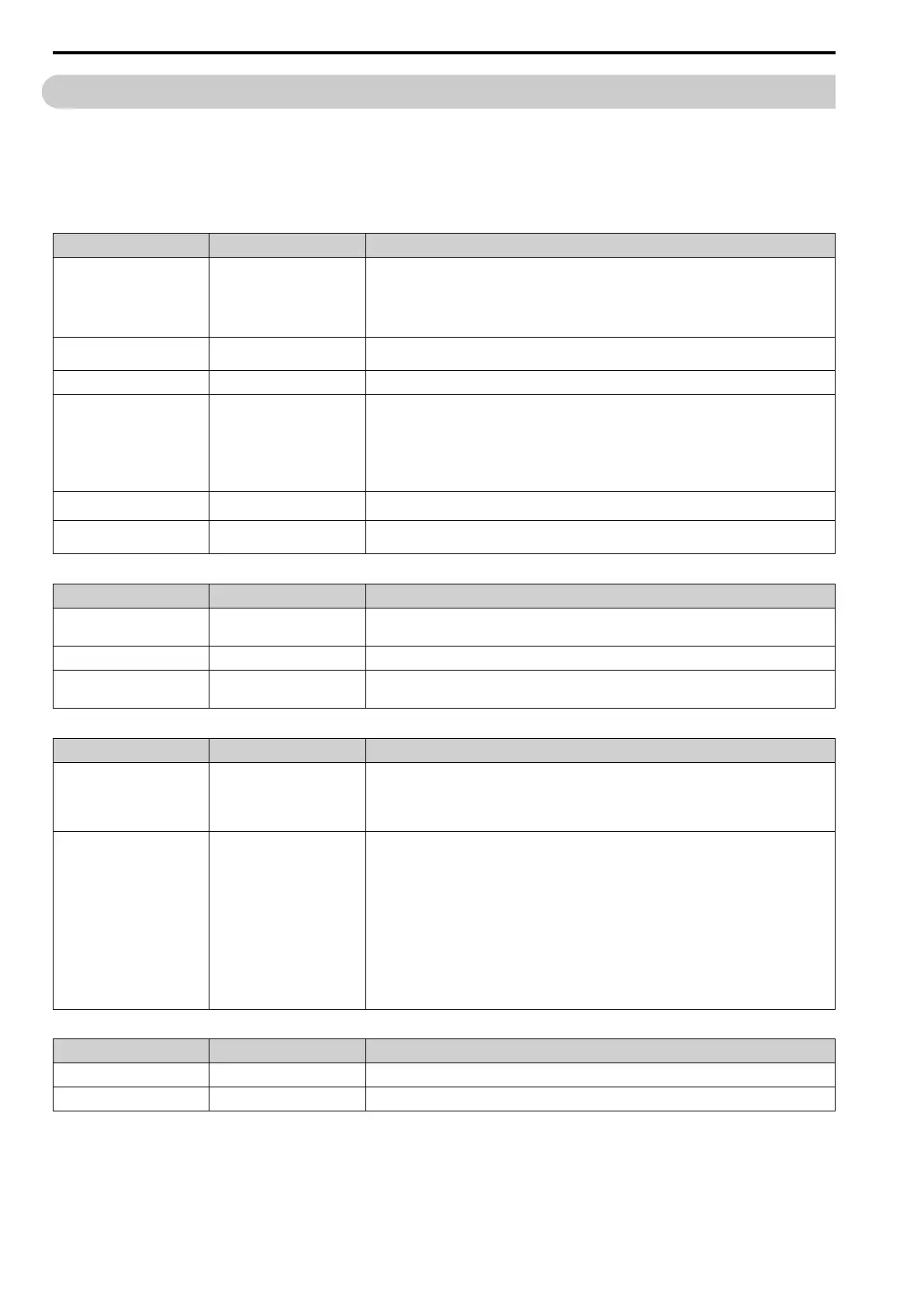

Table 10.74 Kit

Name Model Intended Use

External Heatsink Mount Kit

900-193-209-001

900-193-209-002

900-193-209-003

Use this option to install the heatsink outside of the control panel.

• 900-193-209-001: 2004 to 2042, 4002 to 4023

• 900-193-209-002: 2056, 4031, 4038

• 900-193-209-003: 2070, 2082, 4044, 4060

UL Type 1 Kit

900-192-121-001

900-192-121-002

900-192-121-003

900-192-121-004

900-192-121-005

900-192-121-006

900-192-121-007

900-192-121-008

900-192-121-009

900-192-121-010

To change an IP20/UL Open Type drive to an IP20/UL Type 1 drive.

• 900-192-121-001: 2004 to 2042, 4002 to 4023

• 900-192-121-002: 2056, 4031, 4038

• 900-192-121-003: 2070, 4044, 4060

• 900-192-121-004: 2082

• 900-192-121-005: 2110, 4075

• 900-192-121-006: 2138, 4089, 4103

• 900-192-121-007: 2169, 4140, 4168

• 900-192-121-008: 2211

• 900-192-121-009: 2257, 2313, 4208 to 4296

• 900-192-121-010: 2360, 4371

Table 10.75 Engineering Tools

Name Model Intended Use

DriveWizard -

To use a PC to program drives and manage parameters.

DriveWorksEZ -

To use a PC to do advanced drive programming.

Loading...

Loading...