Troubleshooting

7

7.10 Troubleshooting Without Fault Display

YASKAWA SIEPC71061705H GA700 Series Technical Manual 377

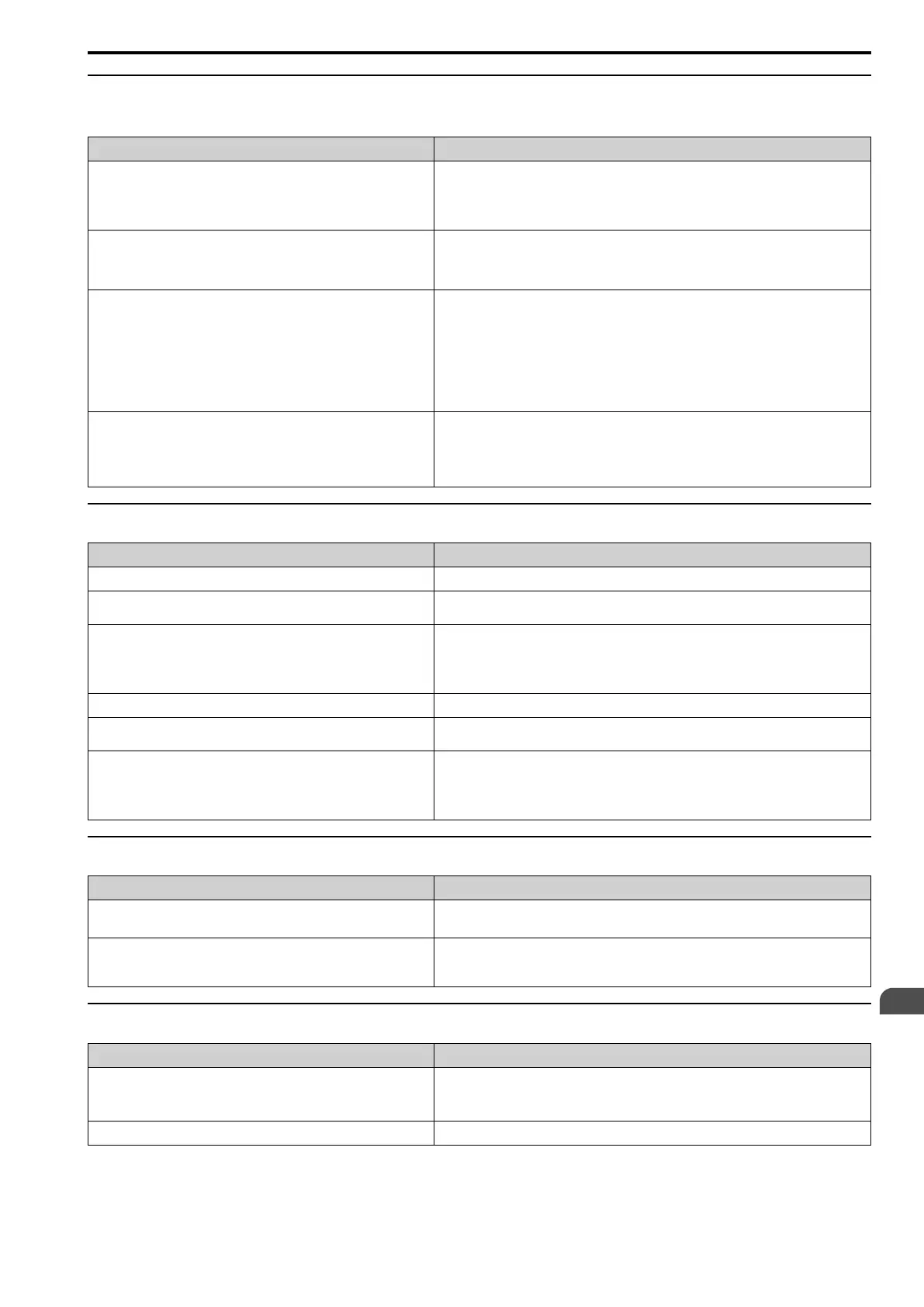

◆ The Drive Frequency Reference Is Different than the Controller Frequency

Reference Command

Causes Possible Solutions

The analog input gain and bias for the frequency reference input are set

incorrectly.

Examine the gain and bias settings for the analog inputs that set the frequency reference.

• Terminal A1: H3-03 [Terminal A1 Gain Setting], H3-04 [Terminal A1 Bias Setting]

• Terminal A2: H3-11 [Terminal A2 Gain Setting], H3-12 [Terminal A2 Bias Setting]

• Terminal A3: H3-07 [Terminal A3 Gain Setting], H3-08 [Terminal A3 Bias Setting]

The drive is receiving frequency bias signals from analog input terminals A1

to A3 and the sum of all signals makes the frequency reference.

• Examine parameters H3-02, H3-10, H3-06 [MFAI Function Select]. If two or more of these

parameters are set to 0, change the settings.

• Use U1-13 to U1-15 [Terminal A1, A2, A3 Input Voltage] to make sure that the analog input

values set to terminals A1, A2, and A3 are applicable.

The motor rotates faster than the frequency reference at low speed. • Decrease the value set in n4-70 [Speed Command Comp @ Low Freq] in increments of 0.1

Hz.

Note:

If you set the value too low, the motor can rotate in reverse.

• Set E1-09 > 0 [Minimum Output Frequency].

Note:

• The recommended setting for E1-09 is 0.5 Hz.

• When frequency reference < E1-09, the drive output will turn OFF.

PID control is enabled. If PID control is not necessary, set b5-01 = 0 [PID Mode Setting = Disabled].

Note:

When PID control is enabled, the drive adjusts the output frequency as specified by the target

value. The drive will only accelerate to the maximum output frequency set in E1-04

[Maximum Output Frequency] while PID control is active.

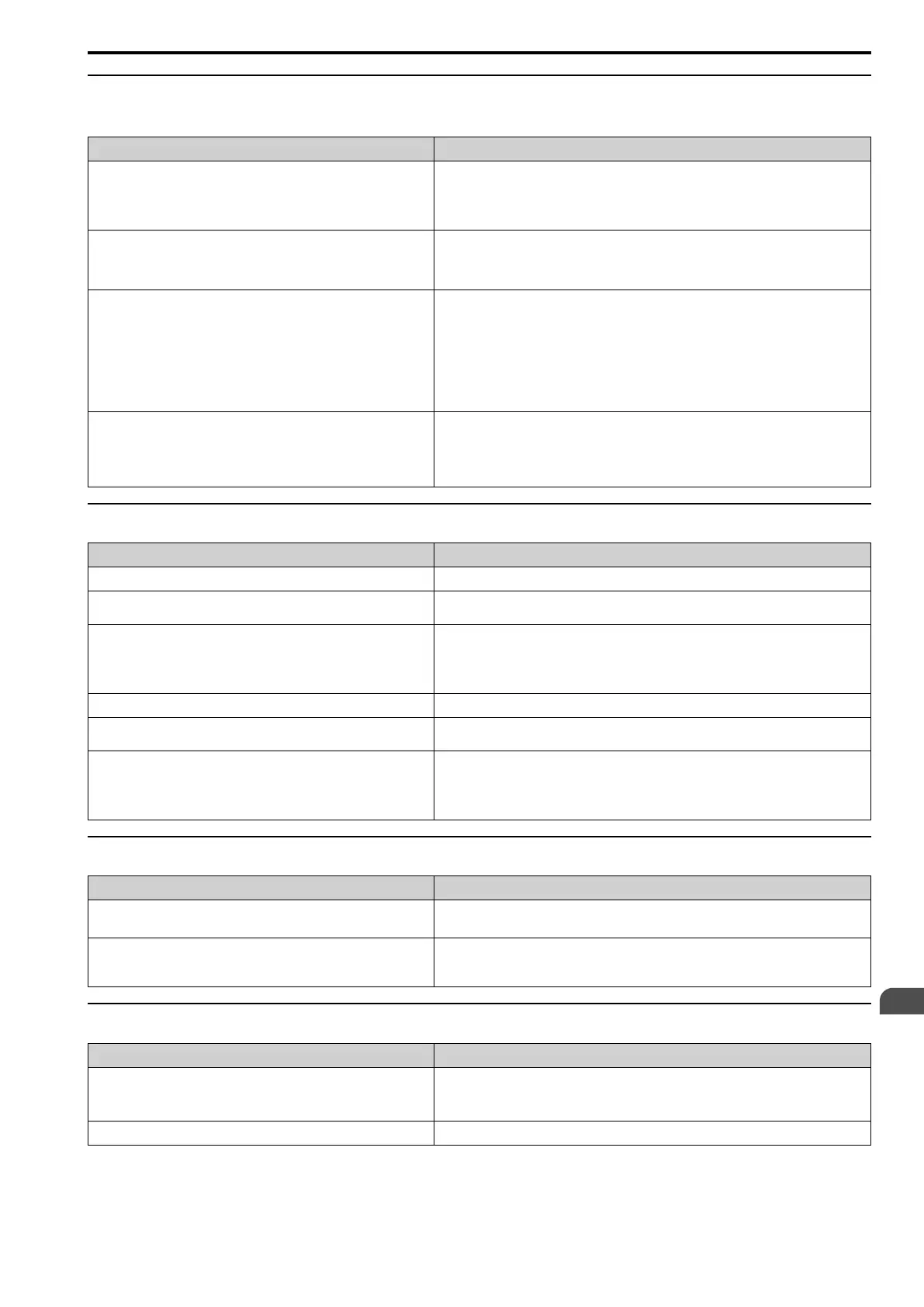

◆ The Motor Speed Is Not Stable When Using a PM Motor

Causes Possible Solutions

E5-01 [PM Motor Code Selection] is set incorrectly. Refer to “Motor Performance Fine-Tuning” in the technical manual.

The drive is operating the motor at more than the specified speed control

range.

Examine the speed control range and adjust the speed.

The motor is hunting. Adjust these parameters to have the largest effect:

• n8-55 [Motor to Load Inertia Ratio]

• n8-45 [Speed Feedback Detection Gain]

• C4-02 [Torque Compensation Delay Time]

Hunting occurs at start. Increase the value set in C2-01 [S-Curve Time @ Start of Accel].

Too much current is flowing through the drive. Set E5-01 [PM Motor Code Selection] correctly as specified by the motor. For special-purpose

motors, enter the correct value to E5-xx as specified by the motor test report.

Operation is not stable when n8-57 = 1 [HFI Overlap Selection = Enabled]. • Do High Frequency Injection Auto-Tuning.

• Decrease the value set in n8-41 [HFI P Gain] in increments of 0.5.

Note:

Set n8-41 > 0.0 for IPM motors.

◆ There Is Too Much Motor Oscillation and the Rotation Is Irregular

Causes Possible Solutions

Unsatisfactory balance of motor phases. • Make sure that the drive input power voltage supplies stable power.

• Set L8-05 = 0 [Input Phase Loss Protect Select = Disabled].

The motor is hunting. • Set n1-01 = 1 [Hunting Prevention Selection = Enabled].

• Increase the value of n2-01 [SpdFeedbackDetectCtr (AFR) Gain] or n2-02

[SpdFeedbackDetCtr(AFR)TimeConst1].

◆ Deceleration Takes Longer Than Expected When Dynamic Braking Is Enabled

Causes Possible Solutions

The stall prevention during deceleration setting is incorrect. • Examine the setting for L3-04 [Decel Stall Prevention Selection].

• When the drive has a dynamic braking option installed, set L3-04 = 0 [Disabled].

• If the drive detects ov [Overvoltage], set L3-04 = 3 [General Purpose w/ DB resistor].

The deceleration time setting is too long. Set C1-02, C1-04, C1-06, or C1-08 [Deceleration Times] to applicable values.

Loading...

Loading...