Startup Procedure and Test Run

4

4.10 Fine Tuning during Test Runs (Adjust the Control Function)

YASKAWA SIEPC71061705H GA700 Series Technical Manual 203

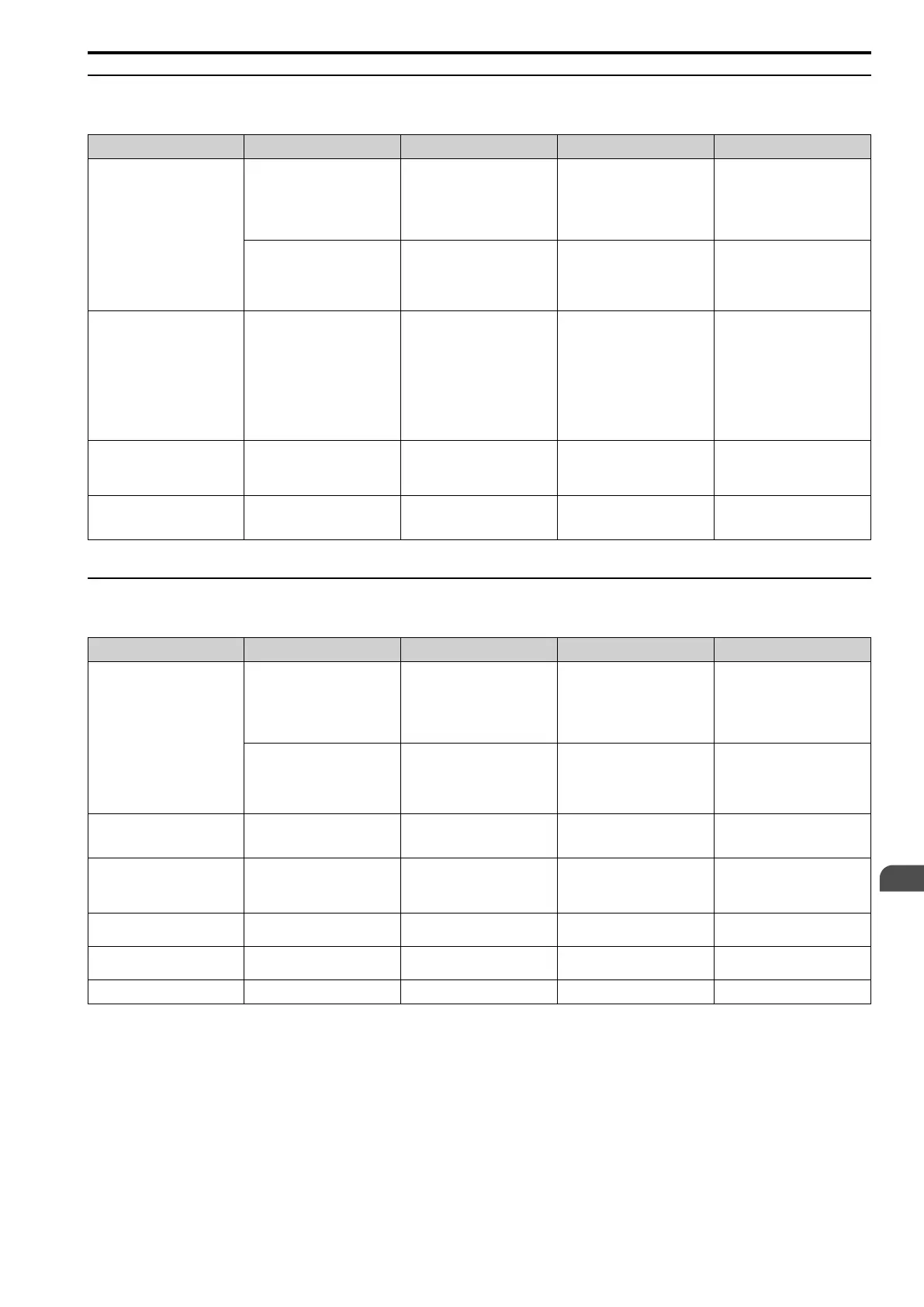

◆ Closed Loop Vector Control Method for PM

Table 4.23 Parameters for Fine Tuning the Drive (CLV/PM)

Issue Parameter Number Possible Solutions Default Recommended Setting

• Unsatisfactory motor torque

and speed response

• Hunting or oscillation

• High speed

C5-01 [ASR Proportional Gain

1]

• Low speed

C5-03 [ASR Proportional Gain

2]

• If torque or speed response are

slow, increase the setting value

in increments of 5.00.

• If hunting or oscillation occur,

decrease the setting value.

20.00 10.00 to 50.00

*1

• High speed

C5-02 [ASR Integral Time 1]

• Low speed

C5-04 [ASR Integral Time 2]

• If torque or speed response are

slow, decrease the setting

value.

• If hunting or oscillation occur,

increase the setting value.

0.500 s 0.300 to 1.000 s

*1

The drive cannot find speed

response for low speed or high

speed.

• C5-07 [ASR Gain Switchover

Frequency]

• High speed

C5-01 [ASR Proportional Gain

1]

C5-02 [ASR Integral Time 1]

• Low speed

C5-03 [ASR Proportional Gain

2]

C5-04 [ASR Integral Time 2]

Change the ASR proportional

gain and ASR integral time to

conform to the output frequency.

• C5-07 = 0.0 %

• C5-01 = 20.00

• C5-02 = 0.500 s

• C5-03 = 20.00

• C5-04 = 0.500 s

0.0% to maximum rotation speed

Hunting or oscillation C5-06 [ASR Delay Time]

If the rigidity of the machine is

unsatisfactory and vibration is

possible, increase the setting

value in increments of 0.010.

0.004 s 0.004 to 0.020 s

*1

Step-out

E1-xx parameters, E5-xx

parameters

Refer to the motor nameplate or

test report and set E1-xx or E5-xx

correctly.

- -

*1 The best values for a no-load operation are different than the best values for actual loading operation.

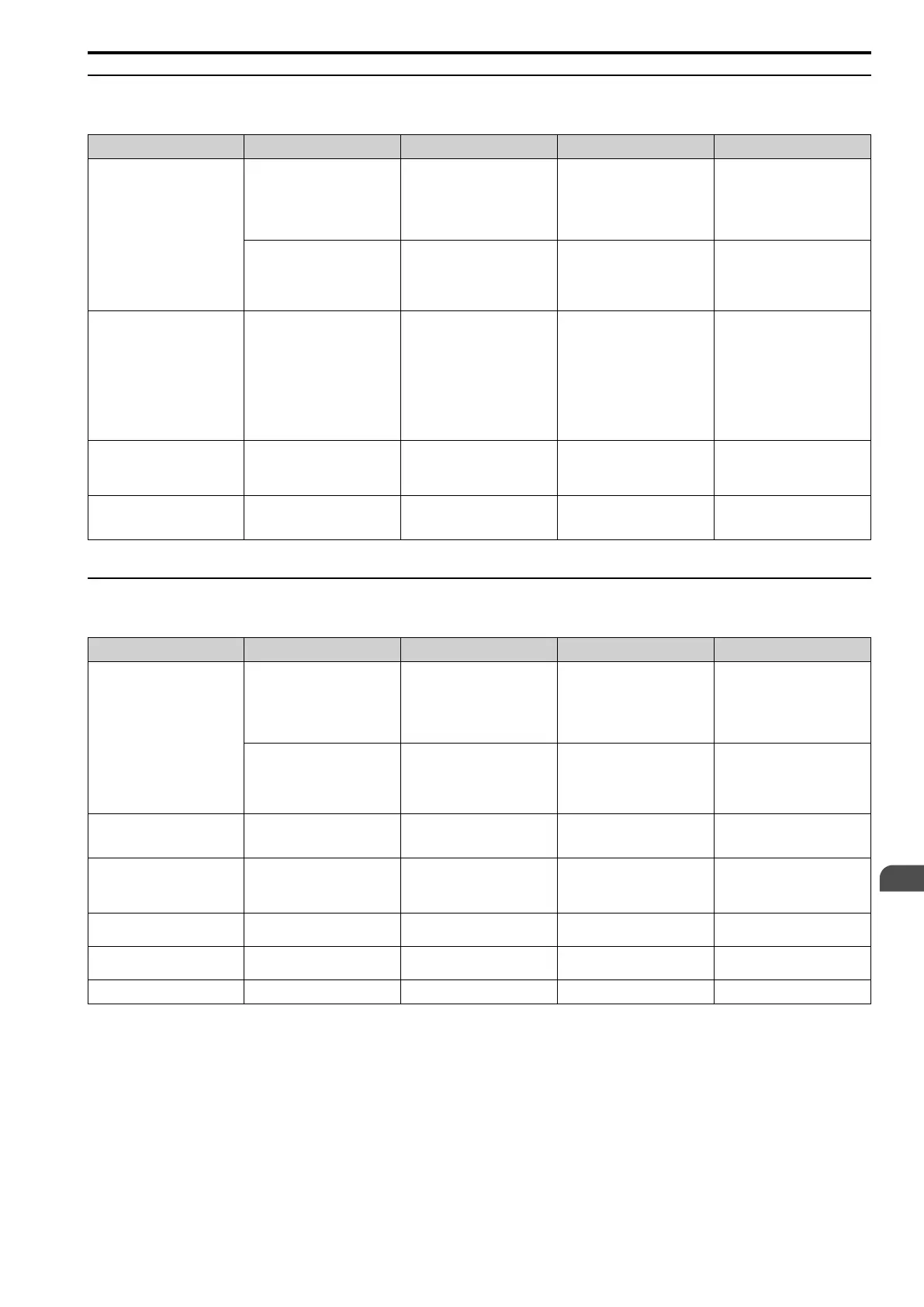

◆ EZ Open Loop Vector Control Method

Table 4.24 Parameters for Fine Tuning the Drive (A1-02 = 8[EZOLV])

Issue Parameter Number Possible Solutions Default Recommended Setting

• Unsatisfactory motor torque

and speed response

• Hunting or oscillation

• High speed

C5-01 [ASR Proportional Gain

1]

• Low speed

C5-03 [ASR Proportional Gain

2]

• If torque or speed response are

slow, increase the setting value

in increments of 5.00.

• If hunting or oscillation occur,

decrease the setting value.

10.00 10.00 to 50.00

*1

• High speed

C5-02 [ASR Integral Time 1]

• Low speed

C5-04 [ASR Integral Time 2]

• If torque or speed response are

slow, decrease the setting

value.

• If hunting or oscillation occur,

increase the setting value.

0.500 s 0.300 s to 1.000 s

*1

The drive cannot find ASR

proportional gain or integral time

for low speed or high speed.

C5-07 [ASR Gain Switchover

Frequency]

Change the ASR proportional

gain and ASR integral time to

conform to the output frequency.

0.0% 0.0% to maximum rotation speed

Hunting or oscillation C5-06 [ASR Delay Time]

If the rigidity of the machine is

unsatisfactory and vibration is

possible, increase the setting

value in increments of 0.010.

0.004 s 0.004 s to 0.020 s

*1

Step-out E9-xx parameters

Refer to the motor nameplate or

test report and set E9-xx correctly.

- -

Oscillation when the motor starts.

n8-51 [Accel / Decel Pull-In

Current]

Increase the setting value. 80% Increase in increments of 5%.

Motor stalls. L7-01 to L7-04 [Torque Limit] Increase the setting value. 200% Increase in increments of 10%.

*1 The best values for a no-load operation are different than the best values for actual loading operation.

Loading...

Loading...