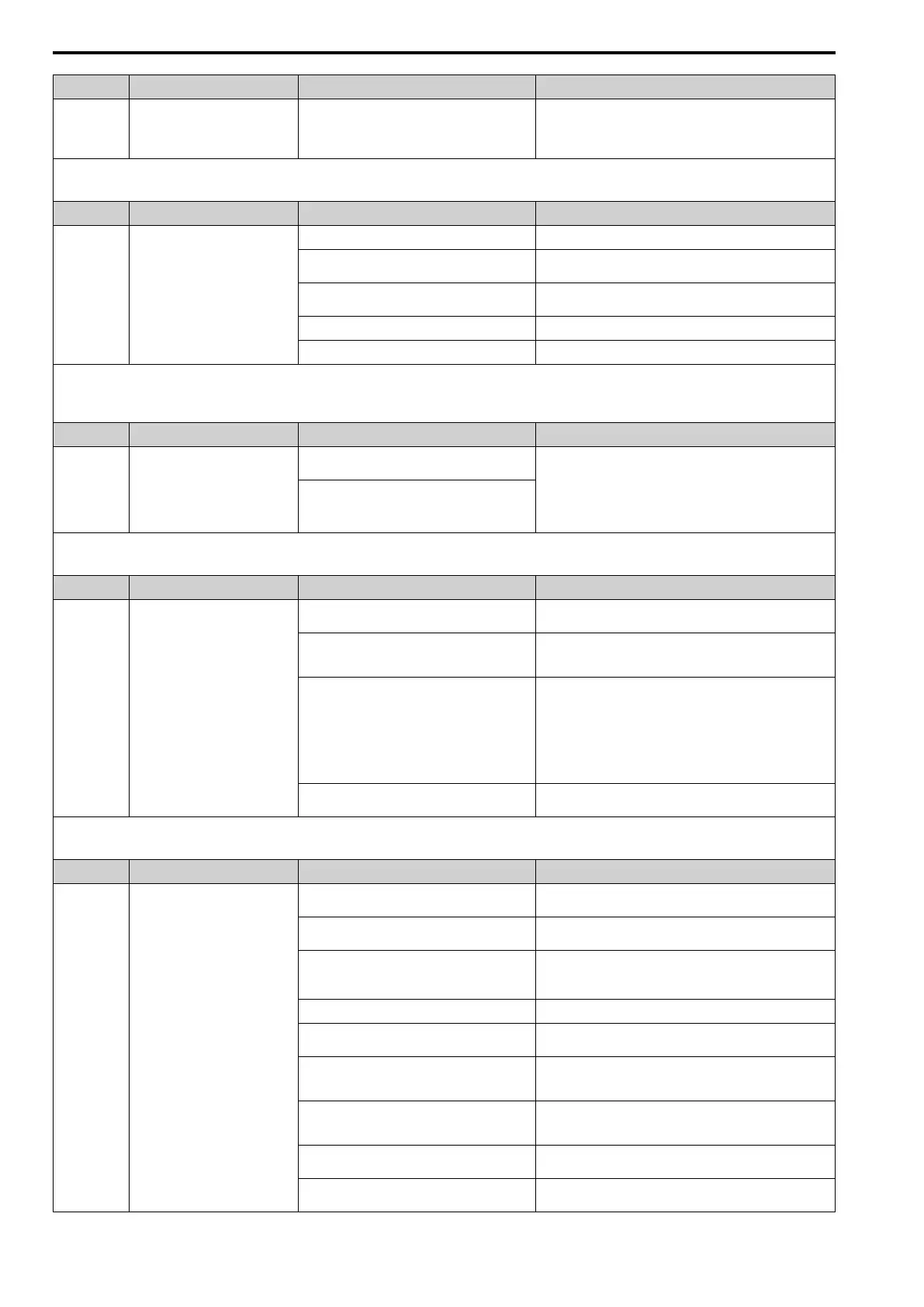

7.4 Fault

326 YASKAWA SIEPC71061705H GA700 Series Technical Manual

Code Name Causes Possible Solutions

CPF39 Control Circuit Error

A drive hardware problem occurred. • Re-energize the drive.

• If the fault stays, replace the control board or the drive. For

information about replacing the control board, contact

Yaskawa or your nearest sales representative.

Note:

• Do a Fault Reset to clear the fault.

• Fault trace is not available for these faults.

Code Name Causes Possible Solutions

dEv Speed Deviation

The load is too heavy. Decrease the load.

Acceleration and deceleration times are set too

short.

Increase the values set in C1-01 to C1-08 [Acceleration/

Deceleration Time].

The dEv detection level settings are incorrect. Adjust F1-10 [Speed Deviation Detection Level] and F1-11

[Speed Deviation Detect DelayTime].

The load is locked up. Examine the machine.

The holding brake is stopping the motor. Release the holding brake.

Note:

• The drive detects this error if the difference between the detected speed and the speed reference is more than the setting of F1-10 for longer than F1-11.

• Do a Fault Reset to clear the fault.

• If the drive detects this error, the drive will operate the motor as specified by the stopping method set in F1-04 [Speed Deviation Detection Select].

Code Name Causes Possible Solutions

dv1 Z Pulse Fault

The encoder option card or the encoder on the

motor side is damaged.

The encoder cable is disconnected or wired

incorrectly.

1. Repair wiring errors and connect disconnected wires.

Correctly ground the shielded wire of the encoder cable.

2. Re-energize the drive

3. If the fault stays, replace the control board or the drive. For

information about replacing the control board, contact

Yaskawa or your nearest sales representative.

Note:

• The drive detects this error if it does not detect a Z pulse during one motor rotation.

• Do a Fault Reset to clear the fault.

Code Name Causes Possible Solutions

dv2 Z Pulse Noise Fault Detection

Noise interference along the encoder cable. Isolate the encoder cable from the drive output line or a different

source of electrical interference.

The encoder cable is disconnected or wired

incorrectly.

Examine for wiring errors or disconnected wires in the encoder

cable, and repair problems. Correctly ground the shielded wire of

the encoder cable.

The drive is operating a motor with 24 or more

poles at zero speed.

• Set F1-46 = 1 [dv2 Detection Method Selection =

MechanicalAngle Detection Method].

• Increase F1-17 [Deviation 2 Detection Selection].

• Increase F1-47 [Deviation 2 Detection Level].

Note:

If you change the setting of F1-47, the sensitivity of detection

for dv2 can decrease.

The PG option or the encoder on the motor side is

damaged.

Repair the wiring and re-energize the drive, then replace the PG

option or the encoder if the problem continues.

Note:

• The drive detects this error if it detects more than one Z pulse per rotation for the number of rotations set in F1-17 [Deviation 2 Detection Selection].

• Do a Fault Reset to clear the fault.

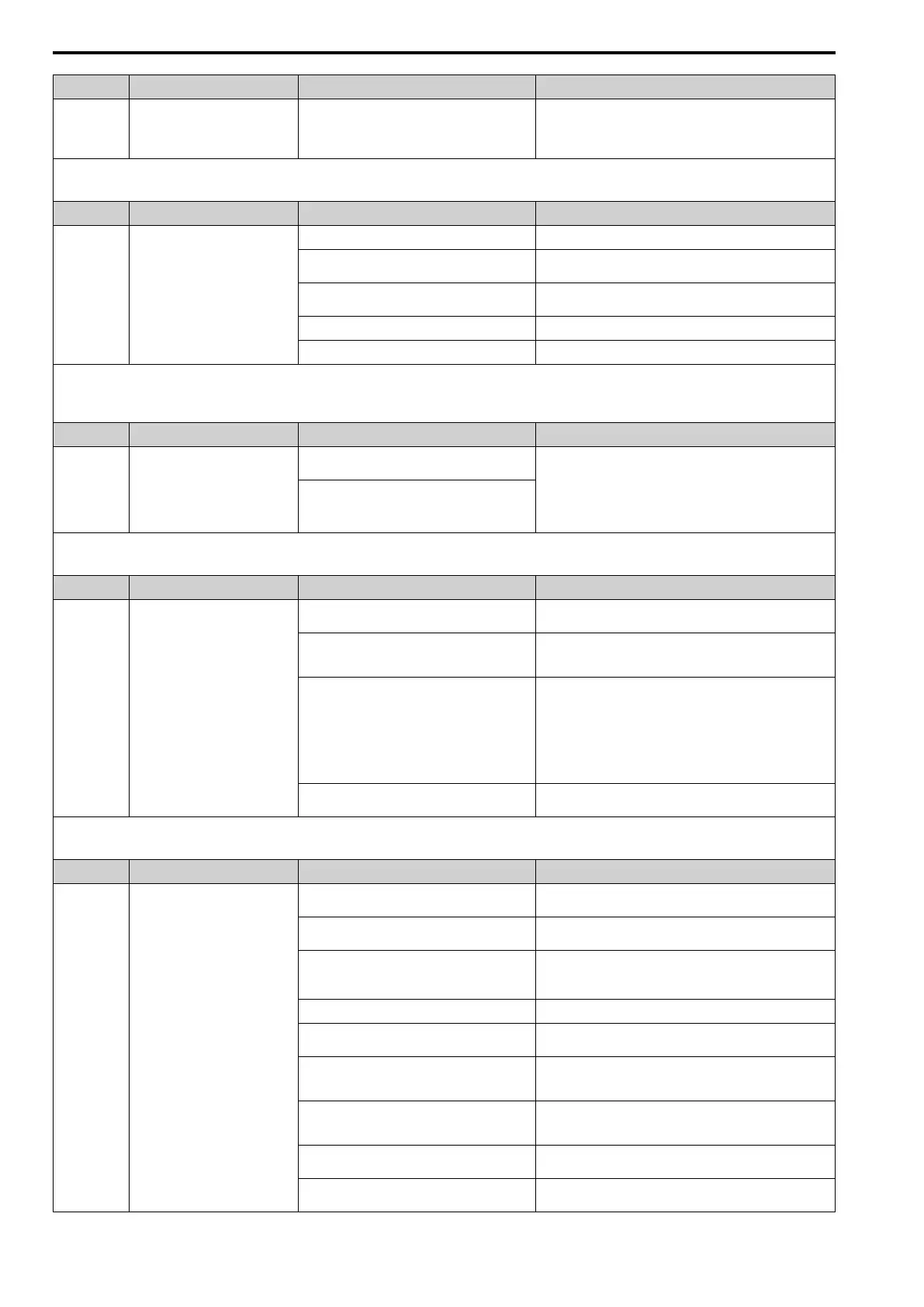

Code Name Causes Possible Solutions

dv3 Inversion Detection

E5-11 [Encoder Z-Pulse Offset] is set incorrectly. Correctly set the value for Δθ to E5-11 as specified by the values

on the motor nameplate.

There is a new encoder or the motor rotation

direction changed.

Do Z Pulse Offset Tuning.

An external force on the load side rotated the motor. • Make sure that the motor is rotating in the correct direction.

• Find and repair problems on the load side that cause the motor

to rotate from the load side.

Noise interference along the encoder cable. Correctly ground the shielded wire of the encoder cable.

The encoder cable is disconnected or wired

incorrectly.

Examine for wiring errors or disconnected wires in the encoder

cable, and repair problems.

The setting for F1-05 [Encoder 1 Rotation

Selection] is the opposite of the direction of motor

rotation.

Correctly connect the motor wiring for each phase (U, V, W).

The drive incorrectly detected the motor magnetic

pole position.

When U6-57 [PolePolarityDeterVal] < 819, increase n8-84

[Polarity Detection Current]. Consult the motor manufacturer for

information about maximum setting values.

n8-84 [Polarity Detection Current] is too low. Increase n8-84 from the default. Consult the motor manufacturer

for information about maximum setting values.

Pole Position Detection failed. If you are using an IPM motor, do High Frequency Injection

Auto-Tuning.

Loading...

Loading...