Malfunctions during crane operation

14.5 Emergency operations and programs

14 - 46 3 302 633 en Operating Instructions GMK5250L

27.09.2017

For the MAXbase

slewing range

type

If the

Standard slewing range type is activated; à p. 14 - 45.

Slewing is not monitored by the RCL in emergency operation.

Due to the wide variety of possible outrigger spans and the asymmetry,

the permissible slewing ranges cannot be representing as simple tables.

When slewing with the hand-held control is unavoidable

• Refer to the lifting capacity table (provided in digital form only) for the

slewing ranges applicable to the current rigging mode.

• Note the slewing range divisions and the permissible (maximum and

minimum) working radii and lifting capacities for each.

Checking the

RCL display

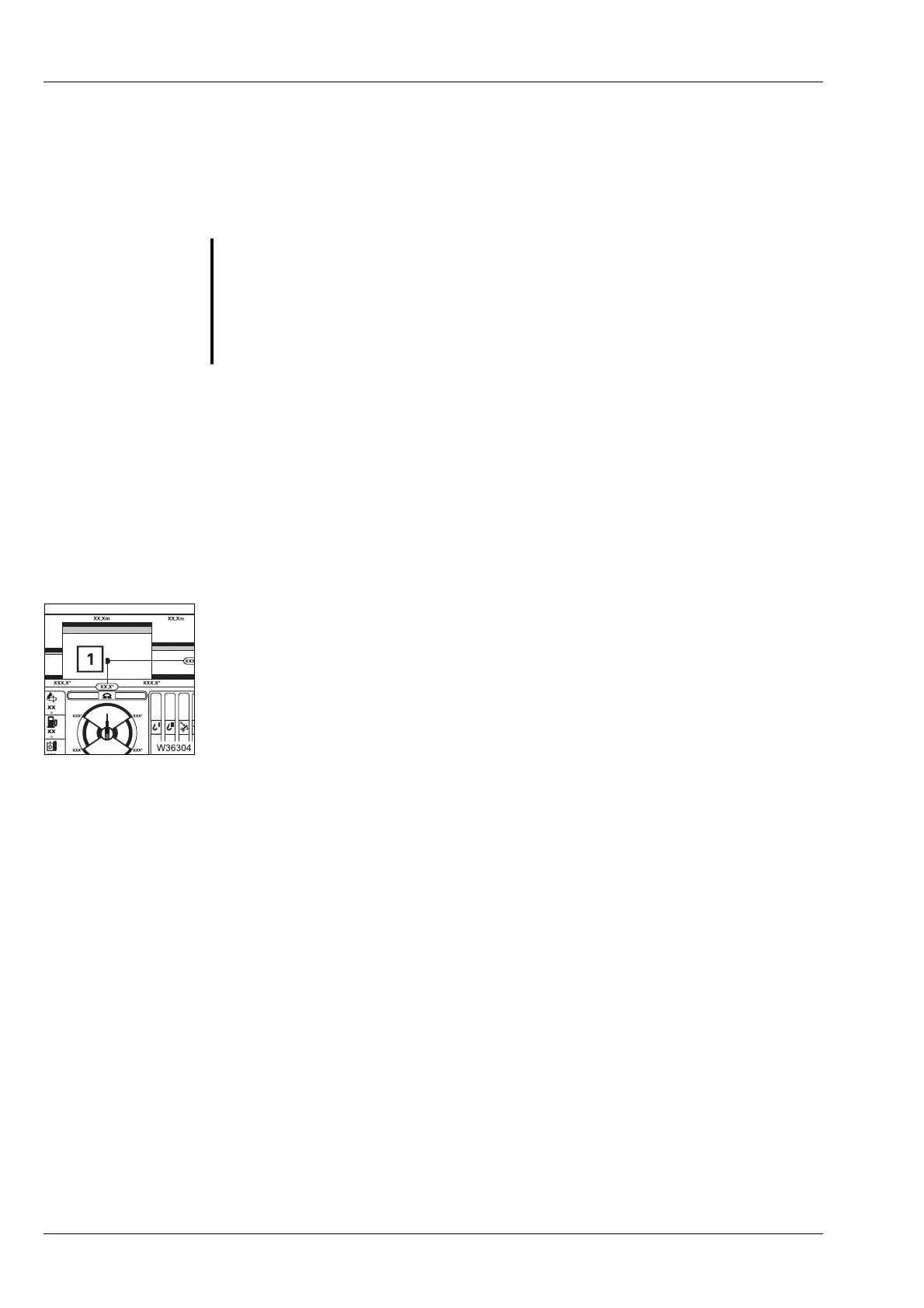

Check that the enabled slewing ranges and working radii specified in the

lifting capacity table are correctly shown on the RCL display.

• Slew slowly towards a safe range and check that the current position (1)

changes accordingly.

• Derrick slowly towards a safe range and check that the current position (1)

changes accordingly.

– If the RCL display still displays correctly

You can use the

RCL display for orientation while slewing and correct the

working radius before reaching the slewing range limits.

– If the RCL does not display correctly

Slew slowly only and monitor the slewing range limits and working radius

based on the values specified in the

lifting capacity table. You may need to

determine the current position via measurements, depending on the

availability of the displays (slewing angle/working radius).

G

Risk of overturning when slewing in emergency operation!

Execute the measures described in this section before slewing and during

slewing. Special caution must be exercised with the

MAXbase slewing

range type because several parameters must be monitored simultane-

ously.

If you have any doubts, contact

Manitowoc Crane Care.

Loading...

Loading...