Rigging work

11.10 Rigging work on the main boom

Operating Instructions GMK5250L 3 302 633 en 11 - 97

27.09.2017

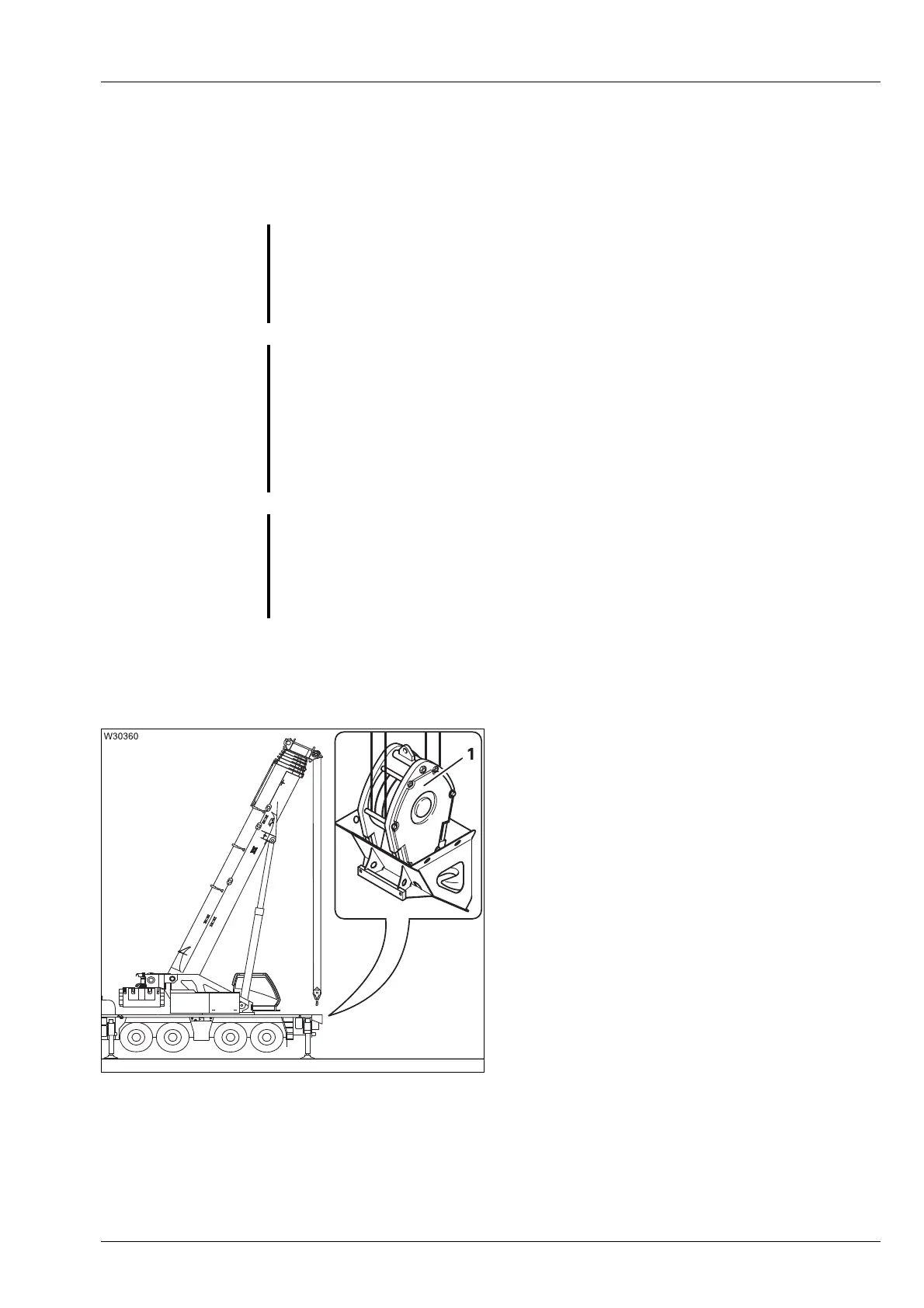

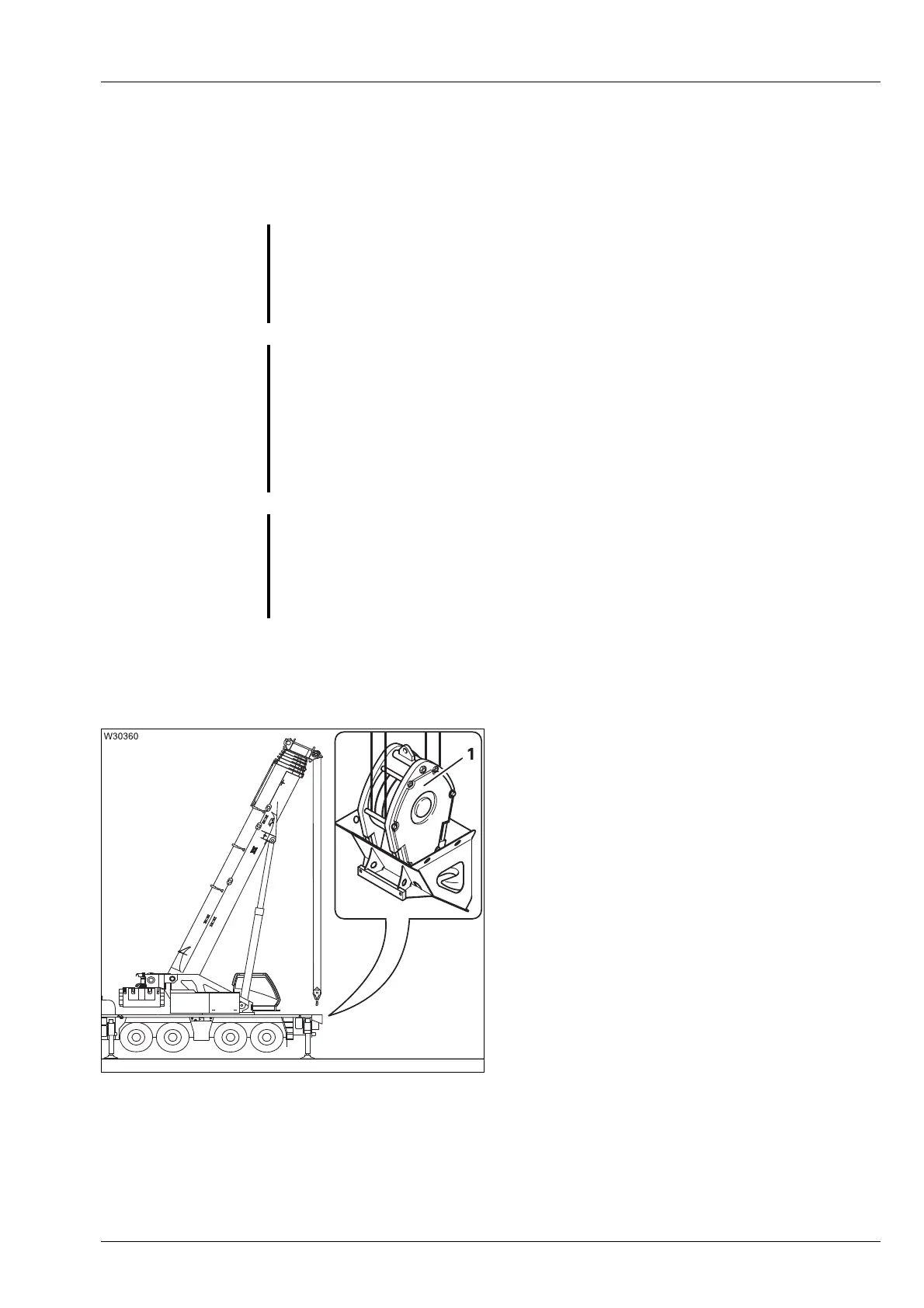

11.10.2 Hook block in the compartment

The hook block or separable hook block, each with 3 or 5 sheaves, can be

stored in the compartment for driving.

Prerequisites – The superstructure is in the position

0° to the rear.

– The boom head is directly over the hook block.

Picking up the hook block

• Remove the lashing straps.

• Unreel the hoist rope.

– Hook block:

• Reeve the hoist rope into the hook block (1);

à Reeving and unreeving the hoist rope,

p. 11 - 104.

– Hook block, separable:

• Attach the sheave package to the hook;

à Hook block, separable, p. 11 - 102.

• Lift the hook block out of the holder.

s

G

Risk of overturning while slewing!

Always check before slewing whether slewing is permitted in the truck

crane's current rigging mode. Correct the rigging mode if necessary;

à Slewing with the rigged counterweight, p. 11 - 93.

G

Danger of overturning when slewing with an overridden RCL!

Do not override the RCL before slewing the superstructure.

If slewing is not enabled then, for the

Standard slewing range type enter a

rigging mode for the 360° working range or for the

MAXbase slewing range

type enter a working radius for which slewing is enabled.

This prevents slewing into impermissible areas and the truck crane tipping

over as a result.

S

Risk of damage to the hoist rope!

To prevent slack rope, do not ease down too much hoist rope when picking

up and reeving the hook block!

Slack rope causes rope loops on the hoist drum, which can result in the load

slipping and the hoist rope being damaged!

Loading...

Loading...