Operation

Central lubricating system

6.20 Central lubricating system

The machine is fitted with a central lubricating system and has two lubricating circuits

in the models with sieve conveyor cleaner and stone remover or three in the model

with 8-setpinch roller cleaner.

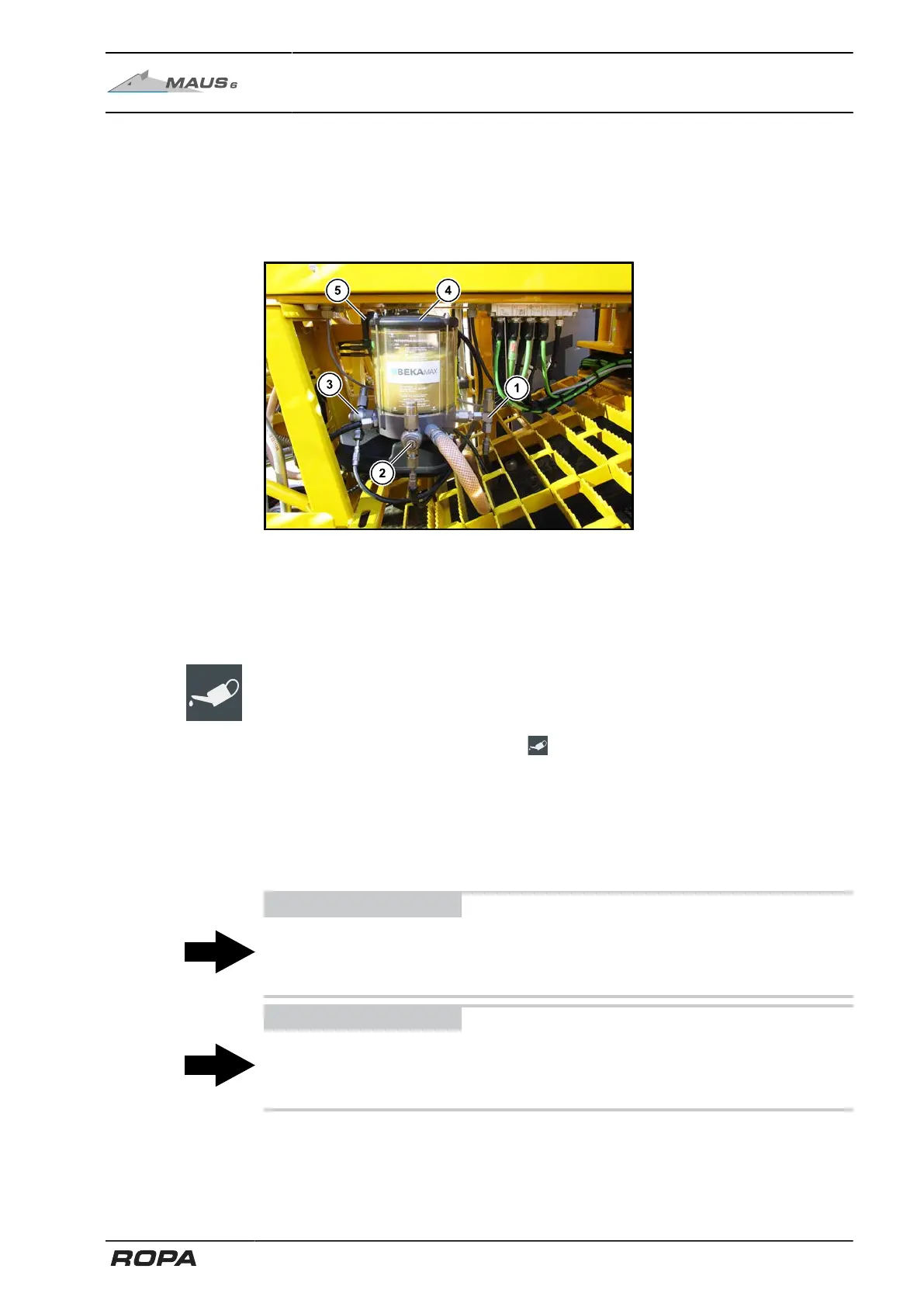

(1) Lubricating circuit 1 support

(2) Lubricating circuit 2 chassis

(3) Lubricating circuit 3 8-set pinch rollers cleaner

(4) 2-kg reservoir

(5) Vent pipe

All connected lubricating points are automatically supplied with grease. The lubricating

pump supplies the grease to the main distributors, the main distributors distribute the

grease to sub-distributors, and these supply it to the individual lubricating points. As

long as the lubricating pump is running, a stirring paddle is rotating in the grease reser-

voir and the R-Touch displays the icon .

Filling the central lubrication system

The 2-kg supply reservoir (4) is filled up via the refill pump (6) on the grease bucket

(7). Never completely fill up the 2-kg supply reservoir of the lubrication pump. Only fill

the supply reservoir of the lubrication pump for 90 %. In this way, you avoid blocking of

the ventilation pipe (5) on the 2-kg supply reservoir.

ADVICE

In any case, make sure that there is always sufficient grease supply in the grease

reservoir. In no case may the grease supply be used up so that air enters the pipe

system!

ADVICE

Fill the 2 kg supply reservoir when the engine is warm from operation as the grease

bucket stands on a heated platform. In such a way refilling is possible with a minimum

effort.

321 / 546

Loading...

Loading...