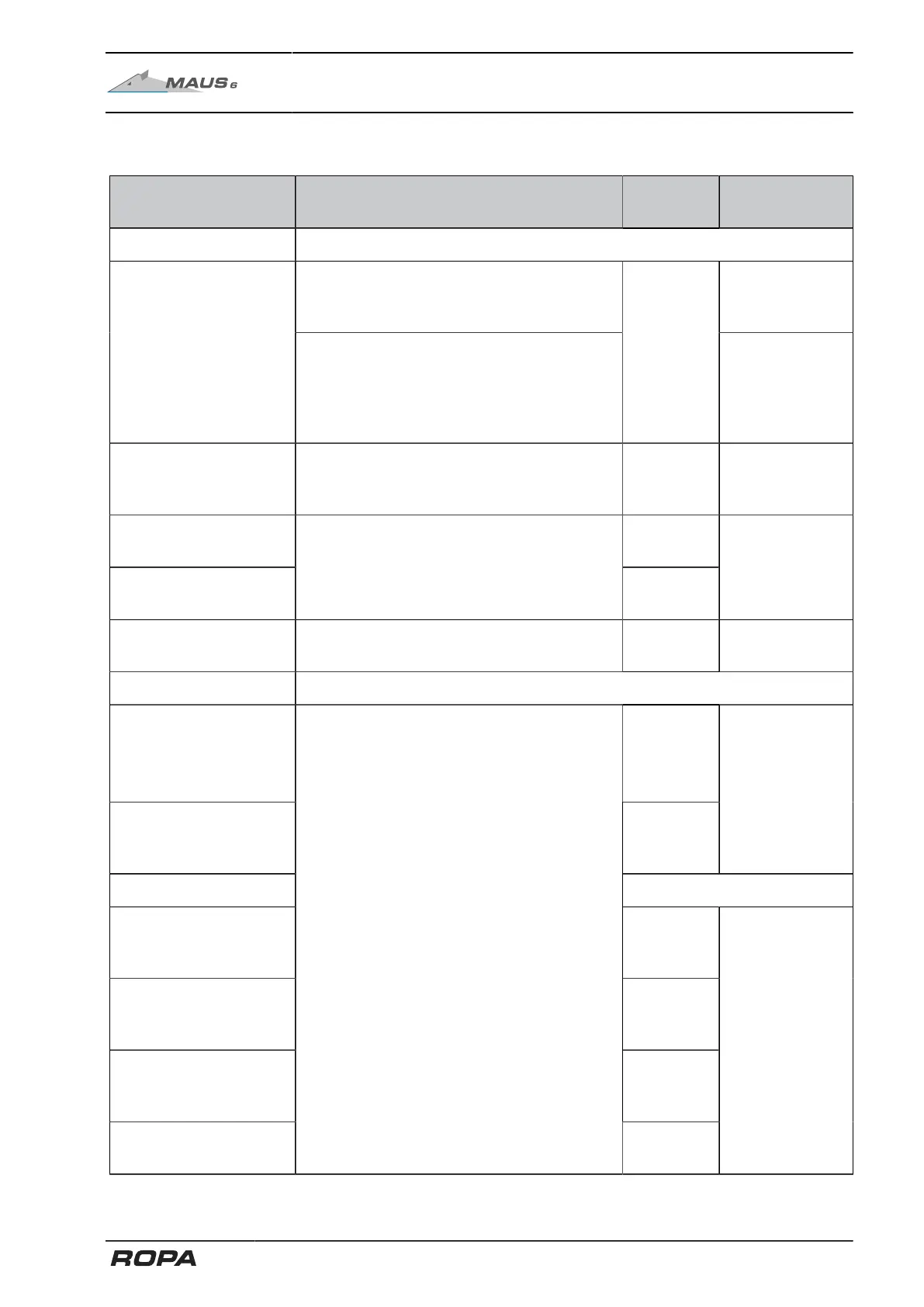

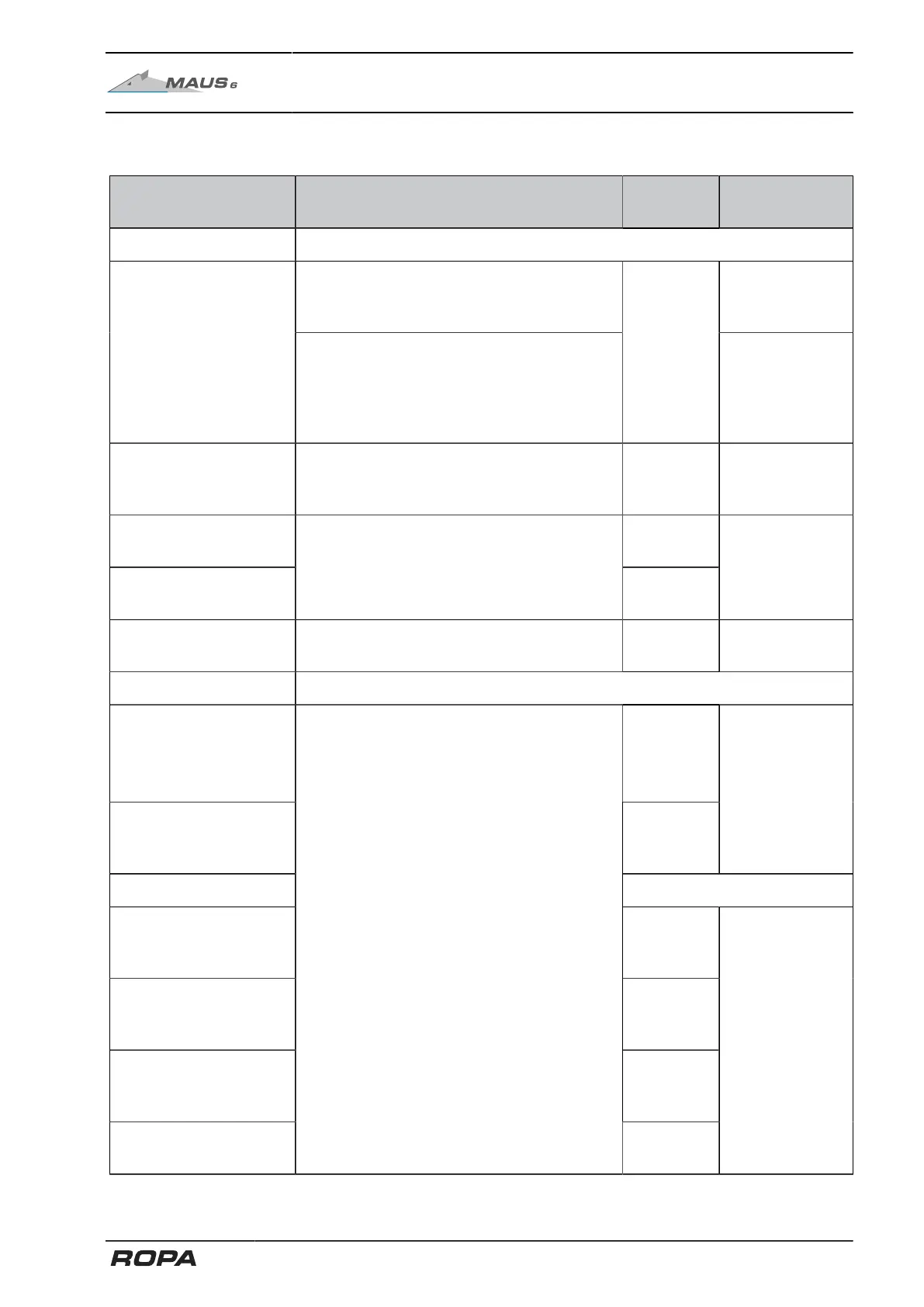

Lists/Tables/Plans/Diagrams/Maintenance Verification

Lubricating and operating supplies

9.1 Lubricating and operating supplies

Component Lubricant type

Filling vol-

ume

Intervals

Diesel engine OM 936

Engine oil, low SAPS

MB standard 228.52

(only for d-diesel engine, with particle filter)

every 1,000

oper. hrs. (See

Page 346)

Engine oil

Engine oil, semi-synthetic

multigrade oil as per MB standard 228.5

MB standard 228.51 is also permitted

(only for a-diesel engine and c-

diesel engine, without particle filter)

approx.

27 litres

every 500

oper. hrs. (See

Page 346)

Cooling system

Corrosion/antifreeze agent -40° as

per MB standard 325.5 and 326.5

(See Page 516)

approx.

25-30 litres

every 3 years

Fuel tank

approx.

1190 litres

Intermediate tank

Diesel fuel

Quality depending on diesel engine variant

and exhaust gas standard (See Page 349)

(approx. 27

l)

when needed

AdBlue® tank AdBlue® DIN 70070 or ISO 22241

approx.

95 litres

when needed

Axles

Differential gears

→ front axle

→ rear axle

approx.

22 litres

approx.

20 litres

Planetary gears

2 axles, 2 pcs. each

each

approx.

3.5 litres

annually

Pickup/cleaning

Pickup rollers gears 2

pcs.

each

approx.

9.0 litres

Gears for conveyor

rollers, 2 pcs.

each

approx.

3.5 litres

Gears for 4 pinch rollers

2 pcs.

each

approx.

1.4 litres

Gears for 8-set pinch

rollers (only with option)

Gear oil

API GL 5, SAE 90

approx.

6.0 litres

annually

501 / 546

Loading...

Loading...